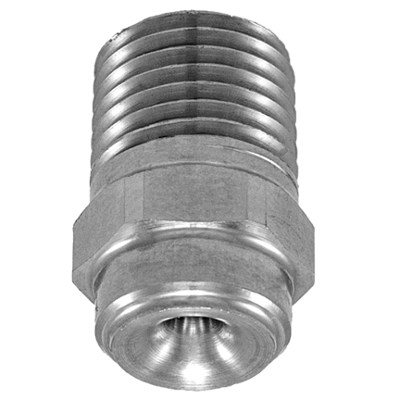

BETE Spray Nozzles for Optimal Product Cooling Applications

BETE provides a range of high-quality spray nozzles designed to efficiently lower the temperature of diverse components and parts. Many manufacturing processes necessitate heating the product during operation and subsequently cooling it to ambient temperature. This applies especially to metal processing industries, including castings, extrusions, and hot-worked products, as well as components subjected to heat treatment. The food industry often packages products at elevated temperatures, requiring subsequent cooling prior to storage and shipping.

Effective Solid Object Cooling with BETE Spray Nozzles

BETE's top-notch spray nozzles designed to efficiently lower the temperature of diverse components and parts. Many manufacturing processes necessitate heating the product during operation and subsequently cooling it to ambient temperature. This applies especially to metal processing industries, including castings, extrusions, and hot-worked products, as well as components subjected to heat treatment. The food industry often packages products at elevated temperatures, requiring subsequent cooling prior to storage and shipping.

Effective solid object cooling is achieved primarily through coolant spraying, typically utilizing water. The cooling rate via water spray is contingent upon factors such as object shape, initial temperature, desired final temperature, object's heat capacity, and convection coefficient between the object and water. The object's shape, taking into account surface area, volume, and indirectly thermal conductivity, plays a vital role. It's crucial to acknowledge that the object's heat transfer capabilities may vary, especially when composed of multiple substances.

Enhanced Cooling Efficiency with BETE Nozzle Spray

The key approach involves evenly distributing a substantial volume of water across the object, ensuring maximum contact and efficient heat transfer from the object to the water. Nozzle spray proves advantageous as it can effectively cover objects of varying shapes. While cooling is a time-consuming process, spraying coolant accelerates it significantly compared to simple submersion. As the object cools down, the water in contact with the object absorbs heat. To maintain the cooling process, it's essential to flush warm water, allowing cooler water to continue the cooling process. This flushing action is an inherent feature facilitated by the liquid flood and spray dynamics generated by a spray nozzle.

Liquid Nitrogen Cooling in Specialized Product Cooling Applications

In specific specialized cooling applications, liquid nitrogen is employed for rapid and cost-effective cooling or freezing of products. The remarkably low boiling point of liquid nitrogen (-320 °F) enables maintenance of extremely low temperatures and high cooling efficiency, particularly in product cooling applications.

Common Applications and Industries for BETE Nozzle Cooling

- Conveyor cooling: cooling cans, bottles, and jars after processing and pasteurization

-

Stationary cooling: cooling larger objects and components that are sitting still

-

Extrusion cooling: accelerate the cooling of extruded products such as wires, tubing, etc. as they travel through a dedicated cooling zone

-

Complex casting cooling: evenly cooling complex components/castings with varying wall thickness

-

Spiral freezing tunnels

-

Steel Industry

Important Factors to Consider When Choosing Product Cooling Nozzles

- Target temperature for cooling object(s)

- Shape of object(s)

- Specific heat of object(s) material

- Speed of travel (if moving)

- Required coverage

- Available and required cooling media flow rate

- Available liquid pressure drop (∆P) across the nozzle

- ∆P = supply pressure at nozzle inlet - process pressure outside nozzle