Pre-Engineered Packages | John Brooks Company

Solutions

Manufacturers

-

- Gorman-Rupp

- Wilden

- Hydra-Cell Sealless Diaphragm Pumps

- Hydra-Cell Metering Pumps

- Summit

- Vaughan

- SEEPEX

- E/One Sewer Systems

- Pulsafeeder EPO

- Pulsafeeder SPO

- Tuthill

- Finish Thompson

- Goulds Xylem

- Grundfos

- Albin Pump

- Almatec

- Ampco

- Blacoh

- CECO Dean

- CECO Fybroc

- Cornell

- Dickow

- Discflo

- Flux

- Graco

- Interpump

- March Pumps

- Mouvex

- Neptune

- Packo Pumps

- Patterson

- Pratissoli

- SANDPIPER Pumps

- Stan-Cor Pumps

- Standard Pump

- Vector Peristaltic Pumps

- Blackmer Gear Pumps

- Price

- Vogelsang

- National Pump Company

- Verderflex

-

Our Customer & Pre-Engineered Solutions

Our highly qualified in-house Engineering Team provides value-added services for customized engineered solutions built to your unique specifications.

Engineering Capabilities include

- 10 dedicated members in the group. 5 are Professional Engineers registered in Ontario. 2 are CETs.

- 2 of which are also registered as P. Engs in Manitoba, Saskatchewan, Alberta and BC.

- Certificates of Authorization for Ontario, Alberta, BC and Manitoba.

- Primary specialties are Mechanical & Electrical, with a lot of experience in pumps, piping and spraying applications. We also have extensive experience with controls, mechanical design and water/wastewater handling & treatment.

- John Brooks has a wholly-owned Fabrication facility called MDA Filtration located in Cambridge, ON. The John Brooks Engineering team handles Pressure Vessel certifications for MDA.

- We have a full-time contract administrator. We also have design and drafting capability using AutoCAD 2015 and are transitioning to 3D.

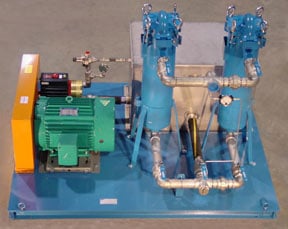

- The group has extensive experience managing municipal and industrial projects that include systems as small as a stand-alone simplex or duplex pump skid up to large, multi-million dollar projects for Shell, Suncor, Fluor, Bantrel, AMEC, etc.

- Our Engineering Systems work primarily focuses on value-added, turn-key skids featuring our core products.

John Brooks Manufacturing Capabilities

- Mississauga Location: In our Mississauga facility on Meadowpine Rd, we specialize in small-scale fabrication and assembly, focusing on pump sets, small system skids, and welding activities (shop employees are “ticketed” welders). Our material handling is limited to items weighing up to 3000 lbs.

- Cambridge Location: MDA Filtration, a John Brooks subsidiary, is a full ASME shop specializing in fabricating large-scale vessels, filtration skids, and Pump Skids. They hold TSSA certification for manufacturing piping assemblies compliant with B31.3 and B31.1. MDA Filtration is certified for pressure vessel fabrication under ASME Boiler and Pressure Vessel Code, Section VIII, Division I. Accredited by the American Society of Mechanical Engineers, they utilize U and UM stamps and adhere to the current edition of CSA Standard B51, Boiler, Pressure Vessels, and Pressure Piping Code. MDA Filtration excels in precision manufacturing with state-of-the-art technology.

Talk to one of our Experts

Reach out to our team of Spraying, Pumping, Filtering, Valve, and Systems Specialists today. We know we can help you with any municipal or industrial application challenges.