BETE Axial Spray Nozzle Made From Chemical-Resistant Plastics

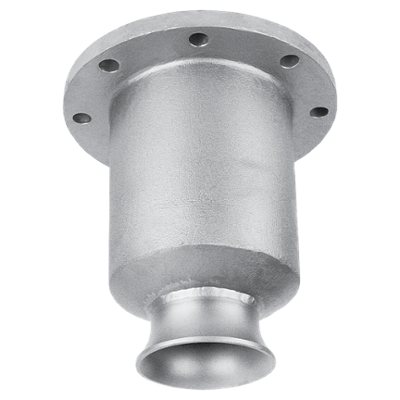

BETE Whirl Nozzles provide uniform distribution of relatively large droplets. Tangential or axial whirl nozzles feature an internal vane within the nozzle body which causes the liquid to “whirl”. The BETE NC Spray Nozzle is part of the BETE Axial Whirl Full Cone Nozzles and produces substantially uniform coverage over a circular area. Choose this nozzle when large particulate is not present.

Design Features of BETE NC Spray Nozzles

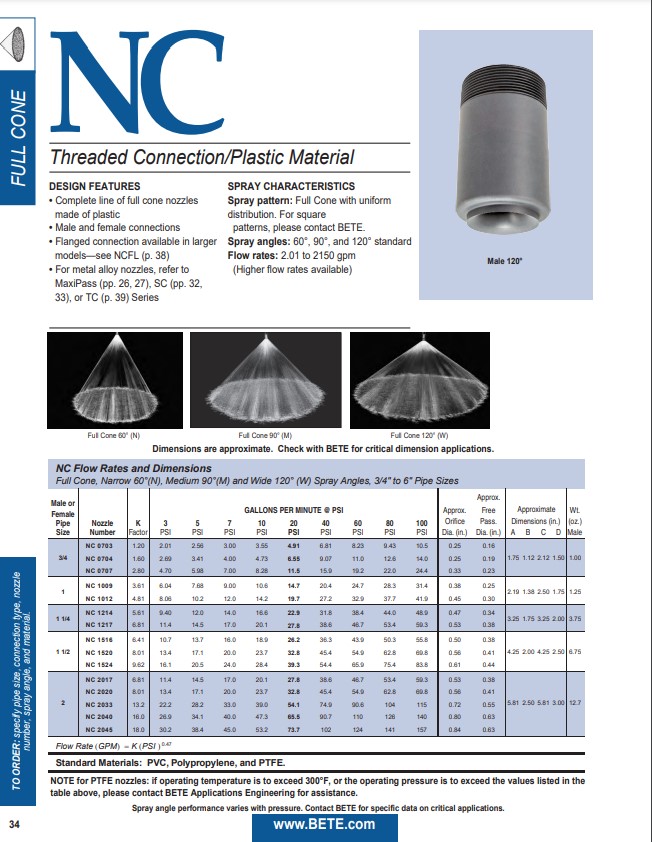

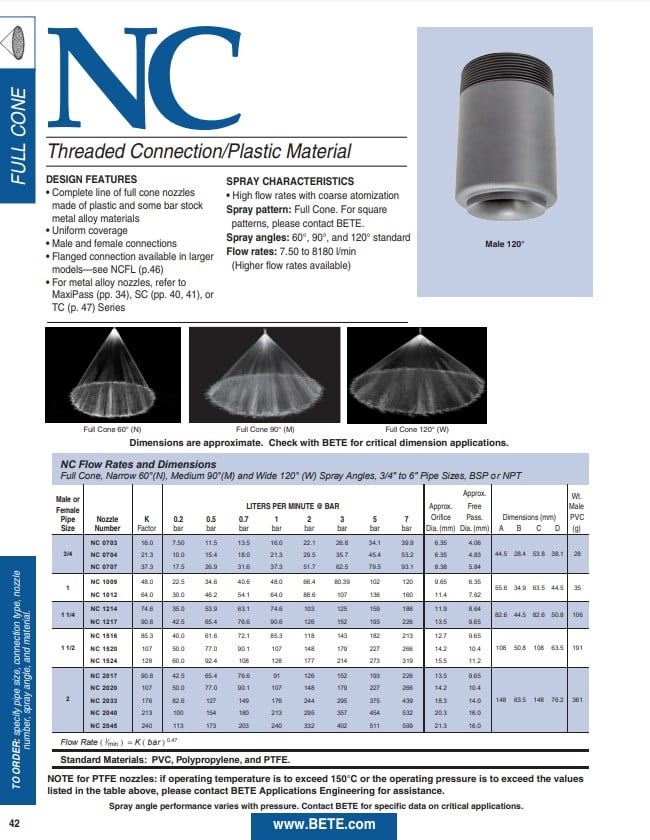

- High flow rates with coarse atomization

- Reliable, uniform coverage

- Manufactured in chemical-resistant plastics and some bar stock metal alloy materials

- Lightweight and rugged

- Made in the USA

- Can be customized to a particular flow rate and angle

- Male and female connections

- Wide range of flow rates and spray angles available

- Wide range of connection sizes and connection types available

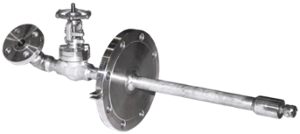

- Flanged connection available in larger models—see NCFL

- For metal alloy nozzles, refer to MaxiPass, SC or TC series

Spray Characteristics of BETE NC Spray Nozzles

- High flow rates with coarse atomization

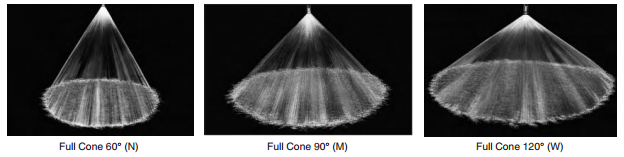

- Spray pattern: Full Cone

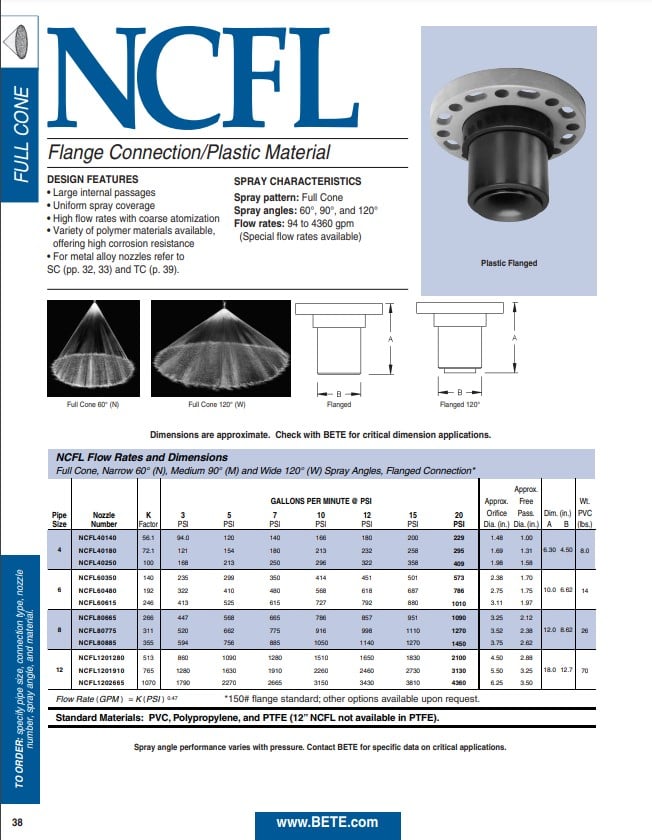

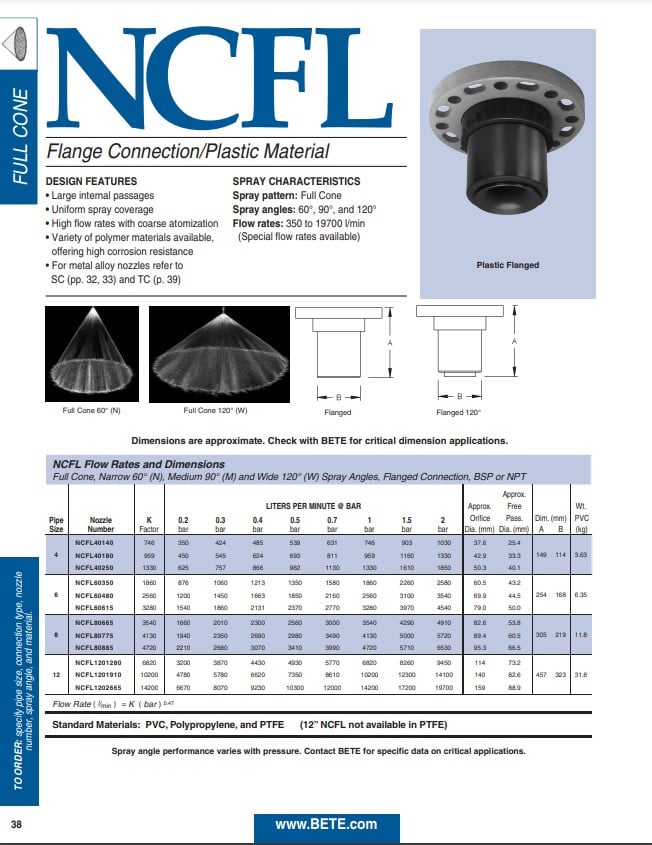

| Available Spray Angles | Flow Rate Range |

| 60 - 120° | 2.01 to 9320 gpm |

| Available Connection Types | Materials |

|

PVC, Polypropylene, PTFE |

BETE NC – Wide Angle, Low Flow:

How Spray Pattern is Achieved on BETE NC Spray Nozzles

- Atomization is achieved by the water being spun inside the nozzle and then exiting an orifice

- High flow rates produce coarse atomization