Very Fine Spray Hydraulic Atomizing Nozzles for Dust Suppression

By using nozzles with very small orifices, a fine droplet size can be attained even at relatively low pressures. Misting nozzles utilize two main technologies; the first is the use of an impingement pin to achieve atomization, the second uses a very small whirl to achieve atomization. When used at higher pressures, direct pressure misting nozzles produce a droplet size that rivals air atomizing nozzles. BETE P Spray Nozzles use liquid “impinges” on pin for extra-fine atomization.

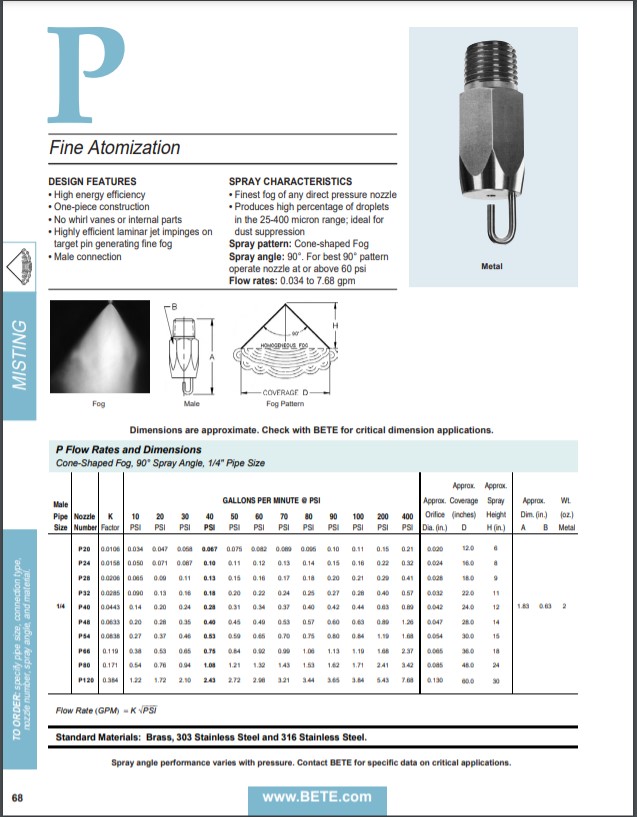

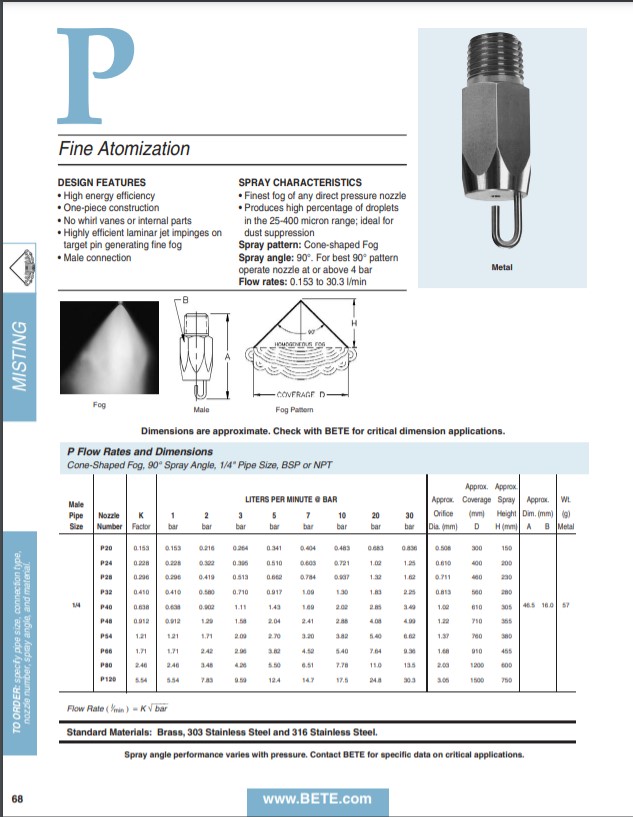

Design Features of BETE P Misting and Fogging Nozzles

- High energy efficiency

- One-piece construction

- No whirl vanes or internal parts

- Highly efficient laminar jet impinges on target pin generating fine fog

- Male connection

- Finest fog of any direct pressure nozzle

- Produces a high percentage of droplets in the 25-400 micron range; ideal for dust suppression

BETE P Misting and Fogging Nozzle Spray Characteristics

- Finest fog of any direct pressure nozzle

- Produces high percentage of droplets in the 25-400 micron range; ideal for dust suppression

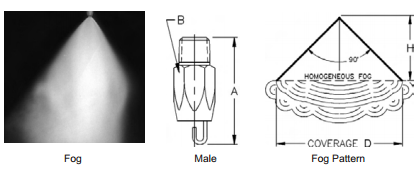

- Spray pattern: Cone-shaped Fog

- Spray angles: 90°. For best 90° pattern, operate nozzle at or above 60 psi (4 bar)

- Flow rates: 0.034 to 7.68 gpm (0.153 to 30.3 L/min)

How Spray Pattern is Achieved

- High pressure shears the liquid by forcing it through tiny openings. An impingement pin distributes the liquid as it leaves the nozzle, deflecting it on the chosen surface.

| Available Spray Angle | Flow Rate Range |

| 90° | 0.0335 to 21 gpm |

| Available Connection Types | Materials |

|

Brass, 303, 316, 310, 321, 347, Nickel Alloy C-276 |

Spray Angle Visual and Drawings

Misting Higher Flow

-Misting-and-Fogging-Nozzles/BETE_MicroWhirl-Head-Image.png)