Vector Pumps Handle Aggressive or Corrosive Fluids, High-viscosity Fluids, and High-purity Solutions

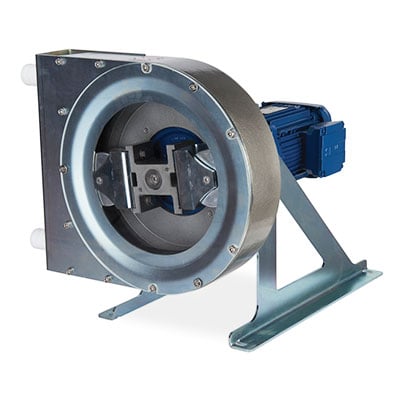

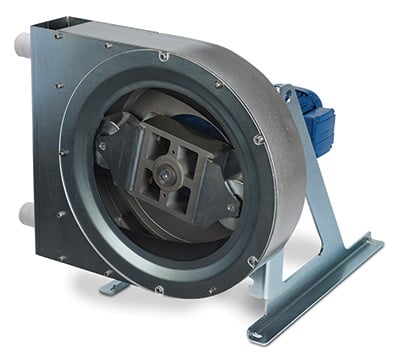

Available in 17 models to handle a wide range of processing requirements, Vector peristaltic pumps are ideal for pumping challenging fluids without altering their composition.

They move high-viscosity (up to 100,000 cps) pasty, pulpy, thick, abrasive, and corrosive solutions as well as fluids containing solids up to 3-1/2 inches (90 mm) in size.

Vector pumps isolate the fluid being pumped into a single, durable hose so they can handle tough fluids.

Advanced Design Features

- Dry pump cavity

- Self-priming operation

- Runs dry without damage

- Complete isolation of fluid pumped

- Heavy-duty roller bearings

- Variety of pump configurations, flows, and pressure ratings

- No dynamic seals, cups or packing to leak or wear

- Reversible flow

- Low maintenance

Typical Substances Handled

- Acids

- Bentonite Slurries

- Carbon Slurry

- Ceramic Slip

- Cosmetics & Creams • Dyes & Inks

- Eggs

- Ferric Chloride

- Flavorings

- Iron Oxide Pigments

- Jams & Preserves

- Lime Slurries

- Paint

- Sewage

- Sodium Hydroxide

- Shampoos

- Yogurt

Typical Industries Served

- Ceramics

- Chemical Processing

- Cosmetics

- Food & Dairy Processing

- Marine

- Mining

- Paints & Coatings

- Petrochemicals

- Pharmaceuticals

- Pulp & Paper

- Water & Wastewater Treatment

Vector Pump Performance Advantages

Pressure Ratings

- Up to 218 psig discharge pressure

Flow Capacities

- Up to 211 gpm

Contamination-free Pumping

- Fluid is contained in the hose and only contacts the hose

Fluid/Hose Compatibility

- Fiber-braided or extruded hoses can handle abrasive or corrosive fluids as well as food products or pharmaceutical materials

Low-shear/Non-emulsifying

- Transfers food and pharmaceutical solutions without crushing or foaming the fluids

Self-priming

- Requires no priming chamber; suction lifts to 29-1/2 feet depending on model

Dry Running

- Externally lubricated hose enables the pumps to run dry without stalling or damaging the hose or roller assembly; avoids pump failure and reducing pump life

Dependable Seal-less Design

- out, or need replacement

Handles Abrasive Solids

- Can pump abrasive fine particles and solids up to 3-1/2 inches (90 mm)

Easy to Clean

- Reversible rotary movement provides for easy-to-clean system piping; flushing may be eliminated

Easy to Service

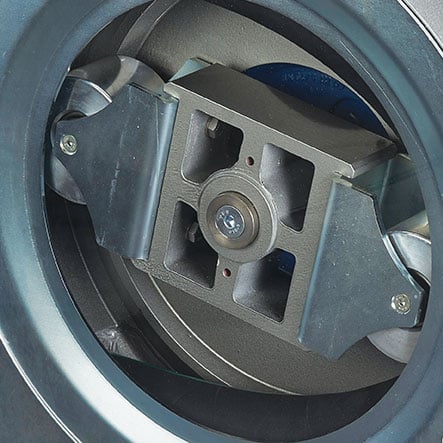

- Simple replacement of hoses saves time; clear plastic cover allows the pump to be checked easily during operation for any problems

Vacuum Capability

- A Vector pump can be used as a vacuum pump and for cleaning up spills; evacuates gases as well as fluids

Dosing Capability

- A Vector pump is also a positive displacement pump for metering; output flow is directly proportional to pump speed

Vector pumps are ideal for several applications in production of industrial and commercial paints, coatings, inks, and dyes.