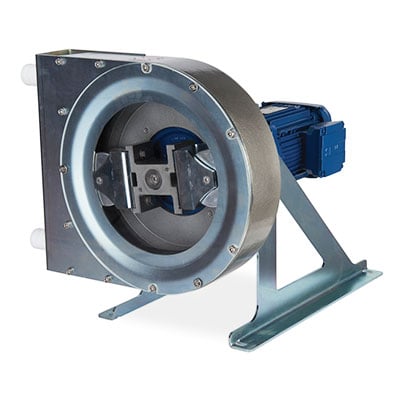

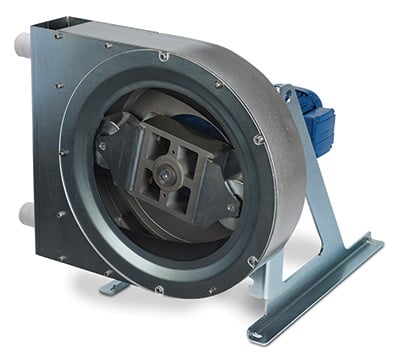

Vector Peristaltic Pump Operating Principle

Vector peristaltic pumps work by compressing and relaxing a hose positioned between a rotating device and a circular pump housing. Vector 2000 Series pumps use rotating rollers that provide the same “push” with far less hose wear.

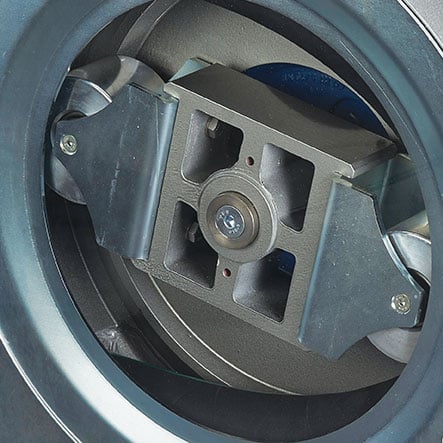

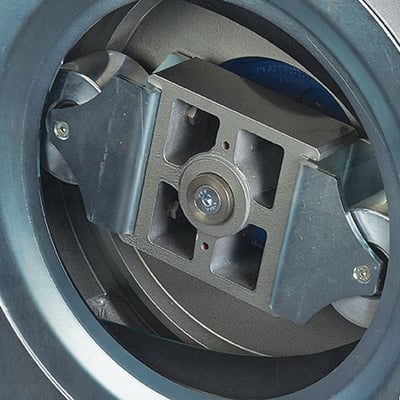

Superior Roller Design

Vector uses an evolutionary roller mechanism instead of a rigid shoe to push fluids through its hose. This ensures longer working life with less downtime for maintenance.

The rollers generate less friction than shoes, extending hose life and reducing downtime.

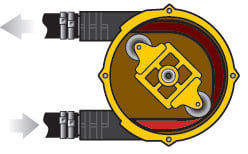

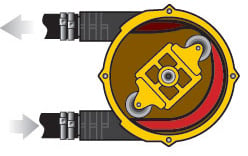

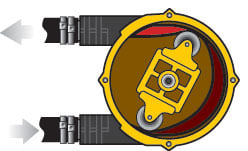

Fluid positioned ahead of the rollers gets pushed forward as the rollers rotate inside of the case.

Meanwhile, the portion of the hose just behind the rollers rebounds to create a vacuum.

The vacuum draws fluid into the pumping hose, which is then pushed forward by the rollers.

Vector Peristaltic Pump Operating Principle

Vector peristaltic pumps work by compressing and relaxing a hose positioned between a rotating device and a circular pump housing. Vector 2000 Series pumps use rotating rollers that provide the same “push” with far less hose wear.

The peristaltic method employed in Vector pumps can create 100% compression at all times. As a result, there is virtually no slipping. Metering is highly accurate. Up to 29-1/2 feet of suction lift is produced.

How do Vector Peristaltic Pumps Operate?

Despite this powerful pumping action, Vector pumps will not cause frothing or delicate emulsions to break up.

Since fluids travel through a single hose, they never come into contact with moving valves, springs, or seals.

This makes Vector pumps ideal for handling abrasive, shear-sensitive, or corrosive fluids. Dyes, thick fluids, and solids up to 3-1/2 inches (90 mm) are also readily pumped.