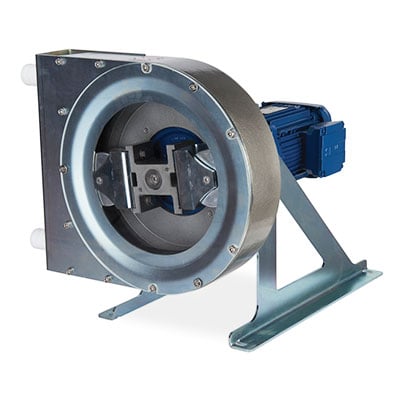

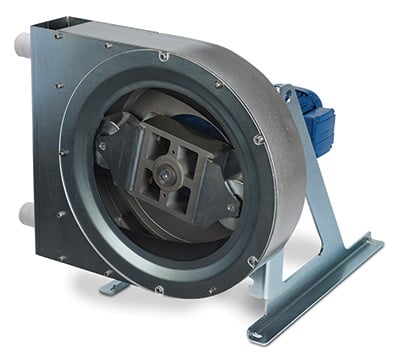

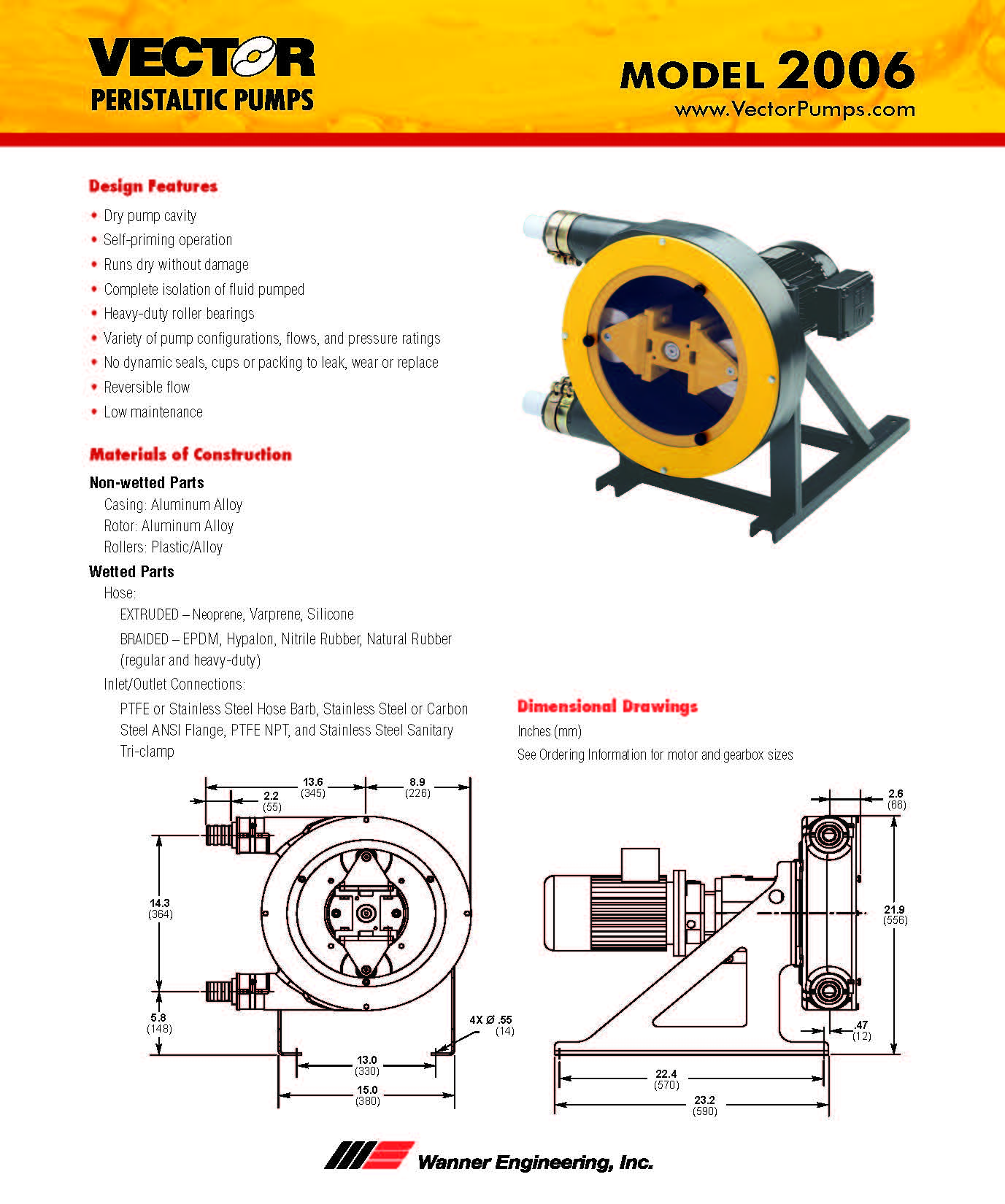

Vector Peristaltic Pump Model 2006

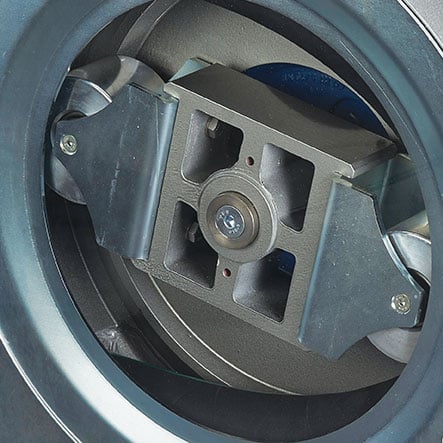

Design Features of Vector Peristaltic Pump Model 2006

The best solution for difficult process fluids

- Dry pump cavity

- Self-priming operation

- Runs dry without damage

- Complete isolation of fluid pumped

- Heavy-duty roller bearings

- Variety of pump configurations, flows, and pressure ratings

- No seals, cups or packing to leak or wear

- Reversible flow

- Low maintenance

Vector Peristaltic Pump Applications

Vector peristaltic pumps can handle the most difficult process fluids to serve a wide range of commercial, institutional, industrial, and municipal markets. Examples of many successful applications are listed in this section - but these are not limitations. If you have a difficult fluid to process not listed, contact one our pump experts for application assistance.

Building & Construction

- Adhesives, dyes, glues, grout, iron oxide pigments, paints, plaster, pottery, tile

Ceramic & Glass

- Clay slips, dyes, enamels, glazes, grinding water, grout, quartz paste, silicon

Chemical Processing

- Abrasive mixes, acids, adhesive resins, caustic soda, detergent paste, latex, pigments, polyester mixes, polymers

Distilleries

- Alcohol, spices, spirits

Electrical

- Polyester slurries for insulating wire

Food & Beverage Processing

- Bentonite and carbon slurries, butter, cake dough, cake frosting, caramel, chocolate, cream, egg yolks with whites, fats, flavorings, fruit juices, gelatins, ice cream, jams and preserves, milk, mustard, potato waste, syrups, tomato sauce, water and salt mixtures, yeast solution, yogurt

Marine

-

Sewage, wastewater, solid waste

Meat Processing

- Acids, animal and waste blood, hair and bone mixtures

Medical, Pharmaceutical & Cosmetics

- Face creams, latex, lotions, plasma, protein solutions, shampoo, vaccines, Vaseline

Mining, Tunneling & Quarrying

- Coal, copper and platinum slurries

Photographic

- Acids, diluents, thinners

Pulp & Paper

- Abrasive, fibrous fluids, aluminum sulfate, boiler wastewater, caustic soda (lye), cold seal, dyes, hydrochloric acid, inks, pre-paint coatings, sulfuric acid

Tanneries

- Acids, dyes, ferrous sulfate, waste fluids with solids

Textile Manufacturing

- Acids, adhesives, bleach, dyes, sizing

Water & Wastewater Treatment

- Acids, activated carbon, aluminum sulfate, caustic soda (lye), ferrous chloride, flocculants, foam inhibitors, lime slurries, solid waste

________________________________________________________________________________________________________________________

Specifications:

| Fluid Characteristics | |

| Viscosity: | 15,000 cps max. |

| Liquid Temperature: | 180°F (82°C) max. |

| Solid Size: | (See Selection Guide) |

| Fiber Length: | 1-7/8 inch (47.6 mm) max. |

| Specifications | |

| Discharge Pressure: | 60 psig (4.1 bar) max. |

| Suction Lift: | 24 ft. (7.3 m) |

| Suction Pressure: | 25 psig (1.7 bar) max. |

| Horsepower:* | 2 max. |

| Hose Size: | 30 x 55 x 1150 mm |

| Displacement: | 0.182 gal/rev |

| Weight (pump only): | 95 lbs. (43 kg) |

| Weight (with drive): | 171 lbs. (78 kg) |

* Pumps are shaft driven and require a gearbox and motor.

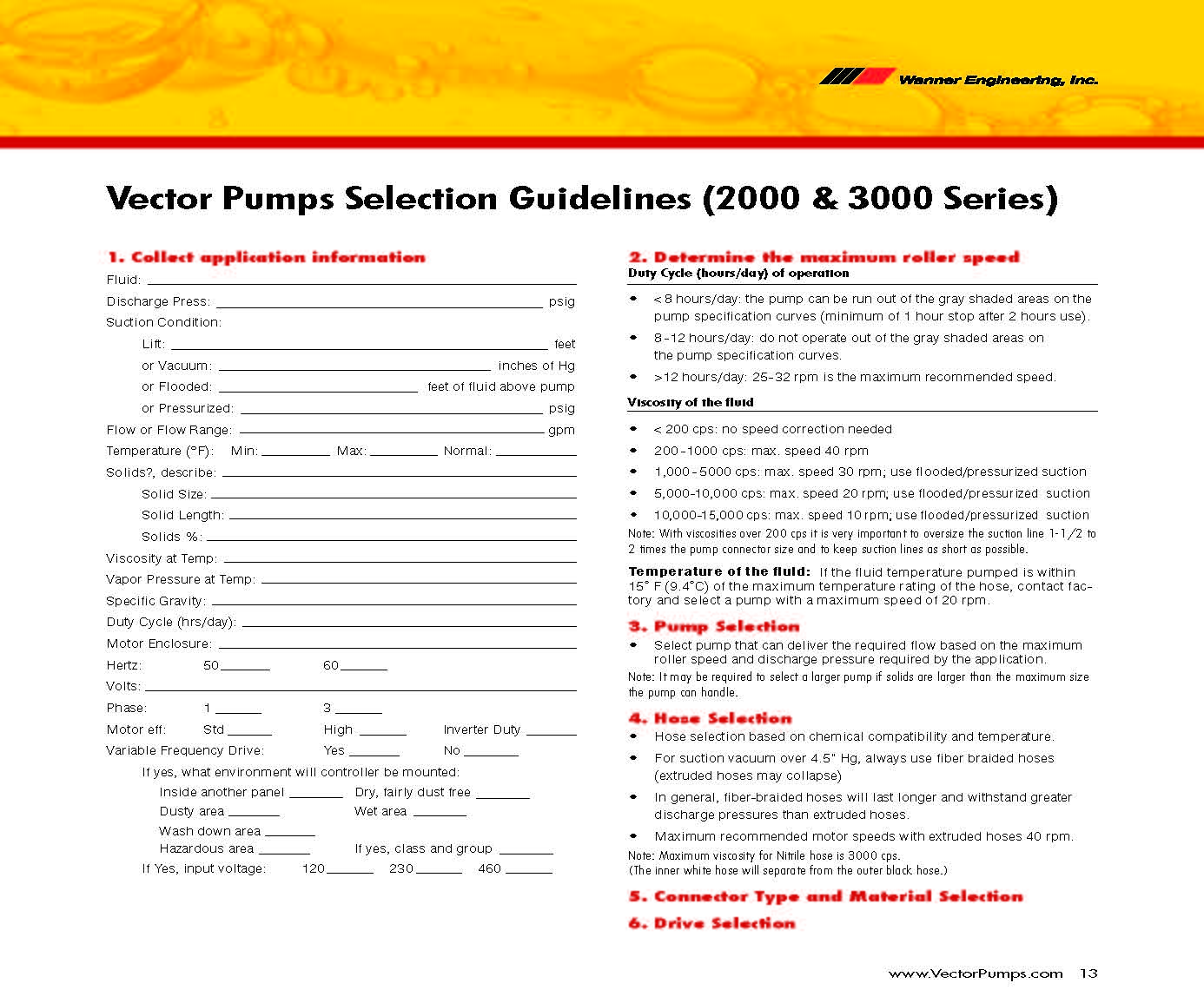

Have a Fluid Handling Problem? We can help you find a Pumping Solution.

John Brooks Company caters to diverse industries, offering suitable pump solutions for nearly all fluid handling needs - including yours! Our success hinges on fostering a collaborative partnership with you, where we help you find a tailored solution to enhance your systems, boost productivity, and minimize operational expenses

Consult with a John Brooks Company Pump expert today to help you determine the most suitable pump type for your application needs.