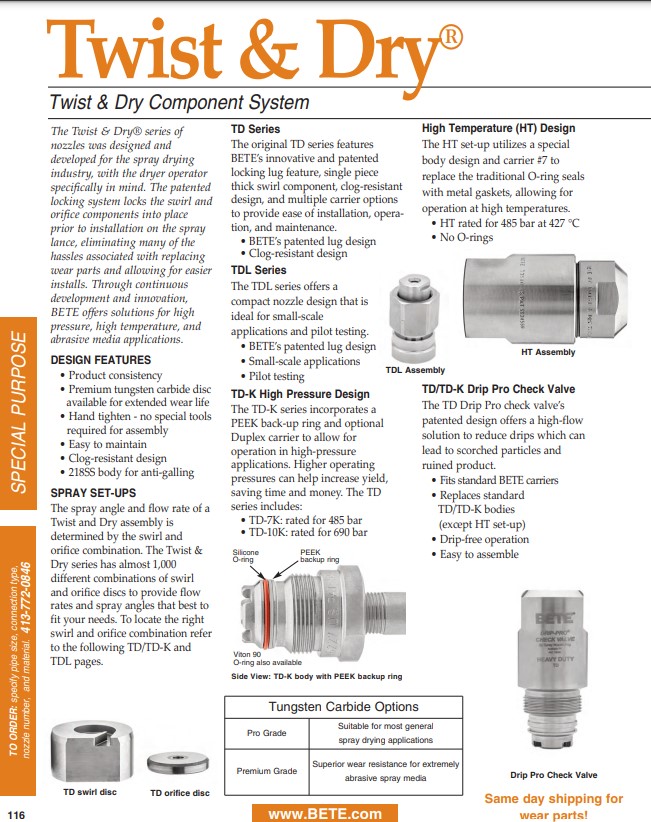

For over 70 years, BETE has been a leading producer of a wide range of hydraulic and air atomizing nozzles designed to meet various spray drying requirements. BETE offers original designs such as the Twist & Dry spray dry nozzle, featuring a patented locking mechanism, aimed at simplifying maintenance. BETE's commitment to consistent performance and quality has made BETE Spray Nozzles a trusted choice among companies, ensuring the production of high-quality products characterized by constant particle sizes and even moisture content.

In a spray dry system, the function of a spray nozzle is critical—it controls the feedstock flow rate and ensures the uniform distribution of atomized droplets/particles into the heated drying chamber. Typically operating at higher pressures or utilizing air atomizing techniques, spray dry nozzles produce droplets in the optimal 30 – 120 micron range. This optimized surface area-to-volume ratio allows for quicker drying compared to other drying methods. In fact, in many dryers, evaporation reaches 95% completion within seconds.

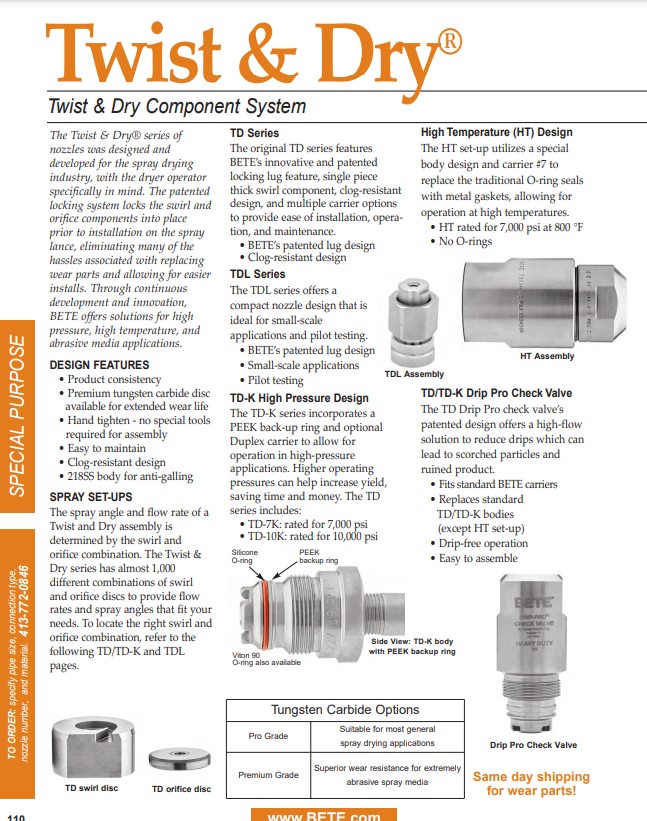

BETE prioritizes durability and safety, which is why their spray dry nozzles are constructed from high strength, wear-resistant, and high-temperature materials. This ensures a long service life and safe operation even in the demanding high-pressure, high-temperature, and abrasive applications often encountered in the spray drying industry. Moreover, BETE provides easy access to replacement orifice discs and swirls to facilitate maintenance.

Common Applications and Industries Served by BETE Spray Nozzles

- Chemical Processing Industry: Detergents, soaps, dyes

- Food and Beverage Processing Industry: Plant proteins, vitamins, pet foods

- Various Powders: Polycarbonate, polyvinyl, cellulose, metal, and ceramic powders

- Powdered Products: Cream/milk, cheese, baby formula, whey, protein, and instant coffee

Important Factors to Consider When Selecting BETE Spray Drying Nozzles

- Available pressure drop (∆P) across the nozzle, calculated as ∆P = supply pressure at nozzle inlet - process pressure outside nozzle.

- Dryer specifications: Size, velocity, pressure, temperature, and humidity.

- Materials of construction: Consider the required materials suitable for corrosive environments.

- Spray media flow rate: Determine the necessary spray media flow rate for your application.

- Spray media properties: Density, viscosity, solids content, and particulate size should align with your specific needs.

BETE Spray Drying Nozzles in Action

/chemical-processing-brochure.jpg)