Low Flow and Compact Carrier Body Spray Dry Nozzles

BETE Whirl Nozzles provide uniform distribution of relatively large droplets. Tangential or axial whirl nozzles feature an internal vane within the nozzle body which cause the liquid to “whirl”. The BETE TDL (low flow, Twist & Dry) spray nozzle is part of the BETE Axial Whirl nozzle product line.

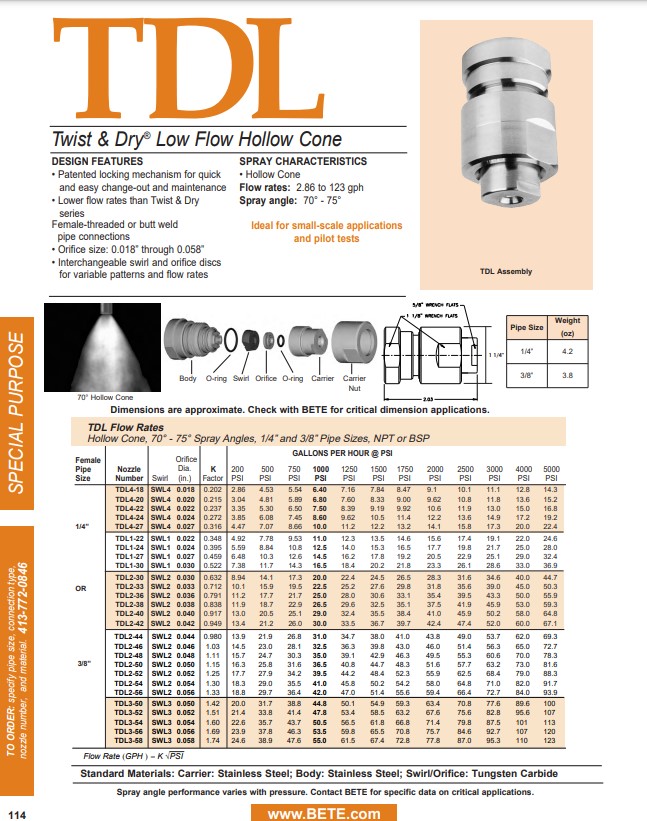

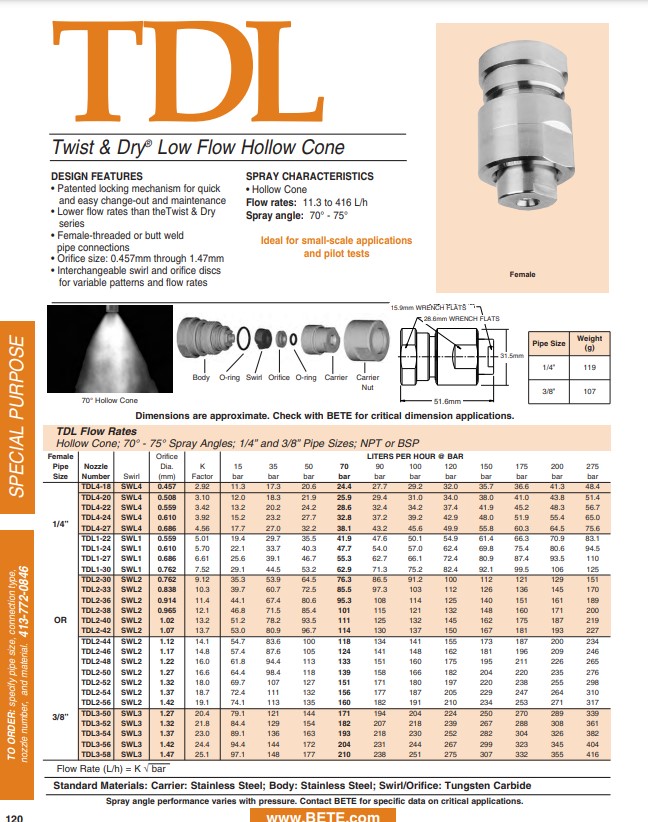

BETE TDL Spray Nozzle Design Features

- Patent pending

- Parented locking mechanism for quick and easy change-out

- 2-piece body for easy maintenance

- Lower flow rates than BETE TD series

- Female threaded or butt weld pipe connections

- Orifice size: 0.018″ through 0.058″ (0.457mm through 1.47mm)

- Interchangeable swirl and orifice discs for variable patterns and flow rates

- Idea for small-scale applications and pilot tests

- Replacement swirls and discs are readily available

Spray Characteristics of the BETE TDL Spray Nozzles

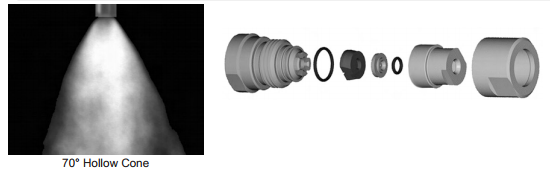

- Spray pattern: Hollow Cone

How Spray Pattern is Achieved

- Spray exits on the same axis it enters

- Internal channels or vanes causes the liquid to spin, and the centrifugal force exerted upon the geometry of the exit creates the spray pattern

- Spray is concentrated on outer edges

- Smaller droplets than full cone

| Available Spray Angle | Flow Rate Range |

| 70° | 0.0476 to 2.05 gpm |

| Available Connection Types | Material |

|

Tungsten Carbide (Pro) / 303 / 218 |

Applications for the BETE TDL Dry Spray Nozzles

- Spray Drying (processing of milk, other foods and chemical products)