Spray Drying Technology for Higher Temperatures

The BETE Twist & Dry (TD) is an axial hollow cone whirl spray nozzle. In general, BETE Whirl Nozzles provide uniform distribution of relatively large droplets. Tangential or axial whirl nozzles feature an internal vane within the nozzle body which causes the liquid to “whirl”.

The hollow cone pattern is characterized by the heavy concentration of droplets around the edge of the spray cone. Little or no fluid is deposited in the middle of the cone. This spray pattern is a medium too low impact pattern being harder driving than the misting or full cone patterns but with less impact than flat fan or solid stream patterns.

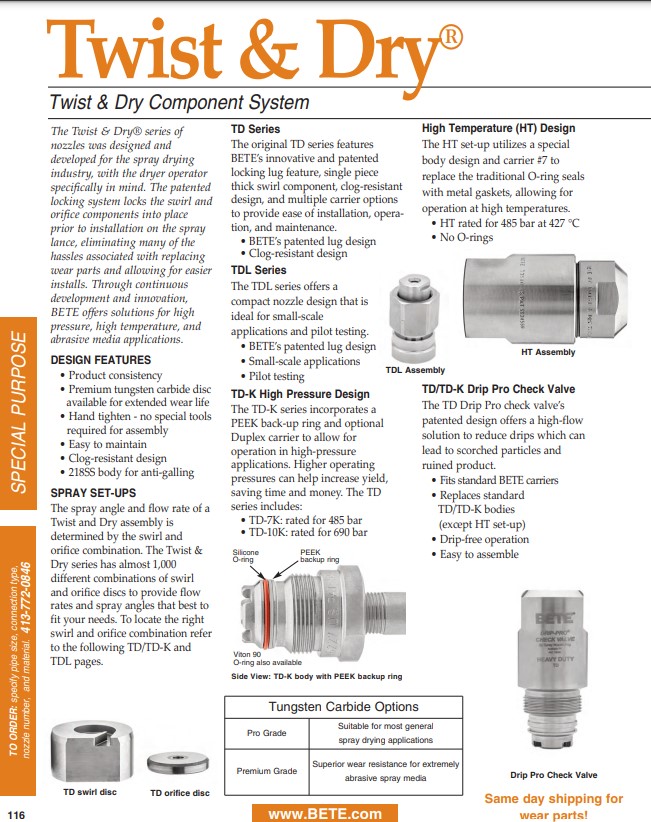

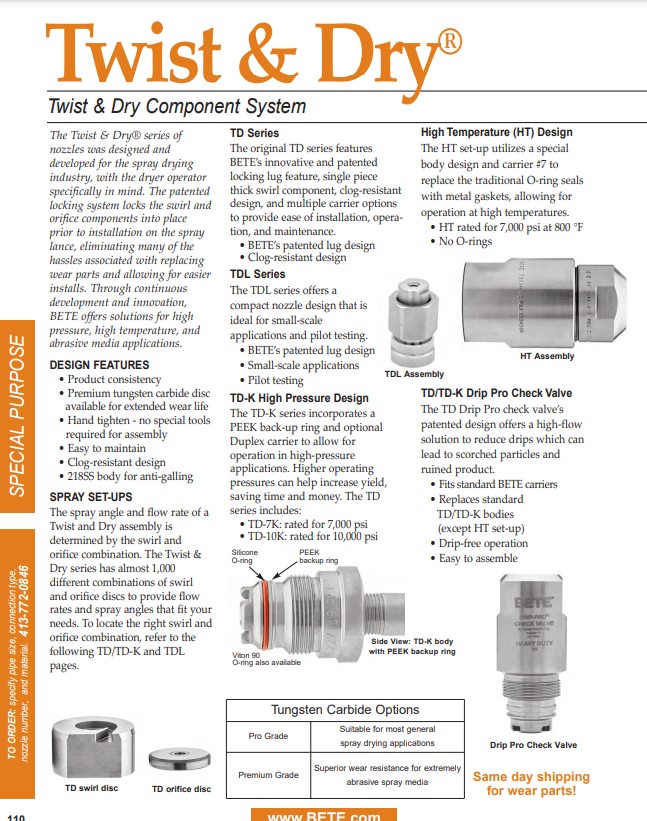

Design Features of BETE Twist & Dry (TD-HT) Spray Nozzles

- Patented locking mechanism for quick and easy change-out and maintenance

- Choose BETE TD-K to operate at high pressures for greater yield capacity

- PEEK backup ring with Viton® 90 or Silicone O-rings (for higher temperatures)

- Female-threaded or butt weld pipe connections

- Easy assembly, no special tools required

- Utilizes a special body design made from alloy 218 and 303 SS carrier rated for high-temperature applications

- Rated for 7,000 psi at 800°F

- Uses metal gaskets, no O-ring seals

- Clog-resistant

- Easy to maintain

- Hollow cone spray pattern available in 0-85 degrees

- Orifice size: 0.034″ through 0.157″ (0.864 mm through 3.99 mm)

- Interchangeable swirl and orifice discs for variable patterns and flow rates

Spray Characteristics of BETE Twist & Dry (TD-HT) Spray Nozzles

- Spray Pattern: Hollow Cone

How Spray Pattern is Achieved

- Spray exits on the same axis it enters

- Internal channels or vanes causes the liquid to spin, and the centrifugal force exerted upon the geometry of the exit creates the spray pattern

- Spray is concentrated on outer edges

- Smaller droplets than full cone