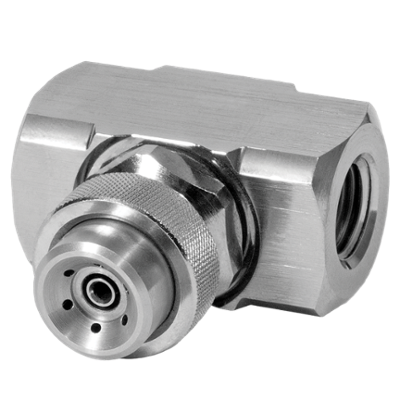

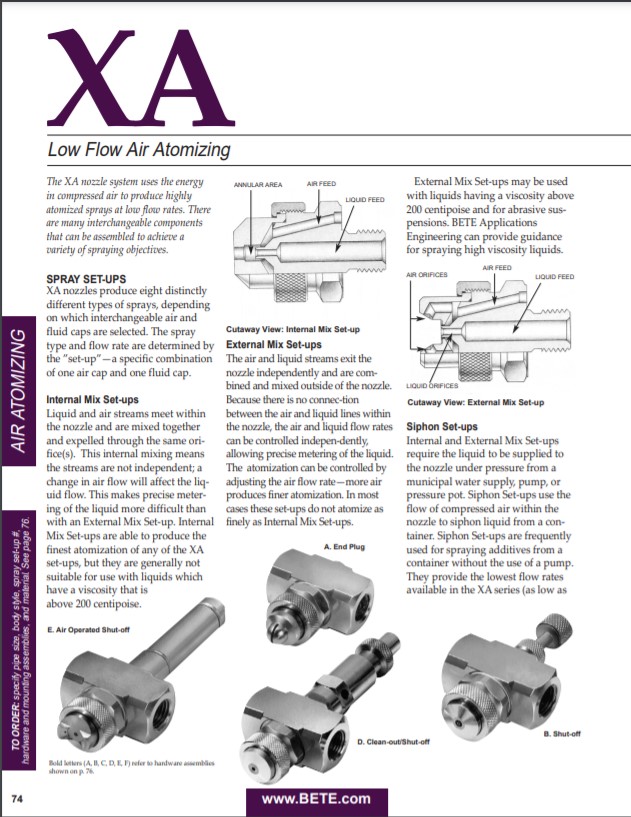

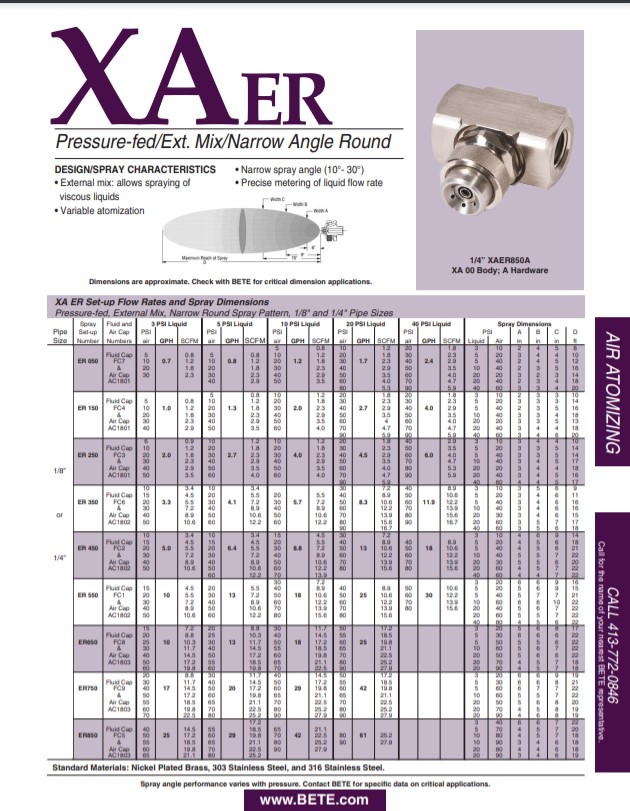

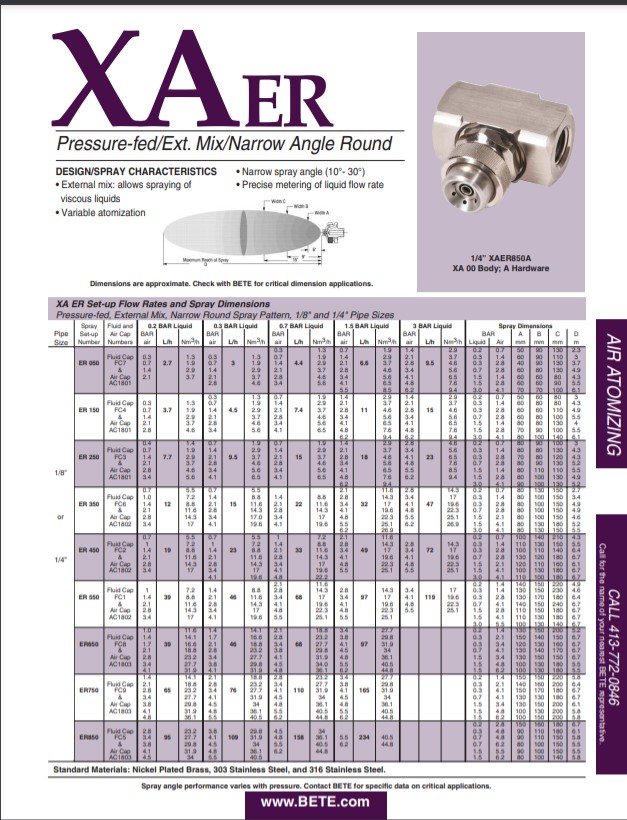

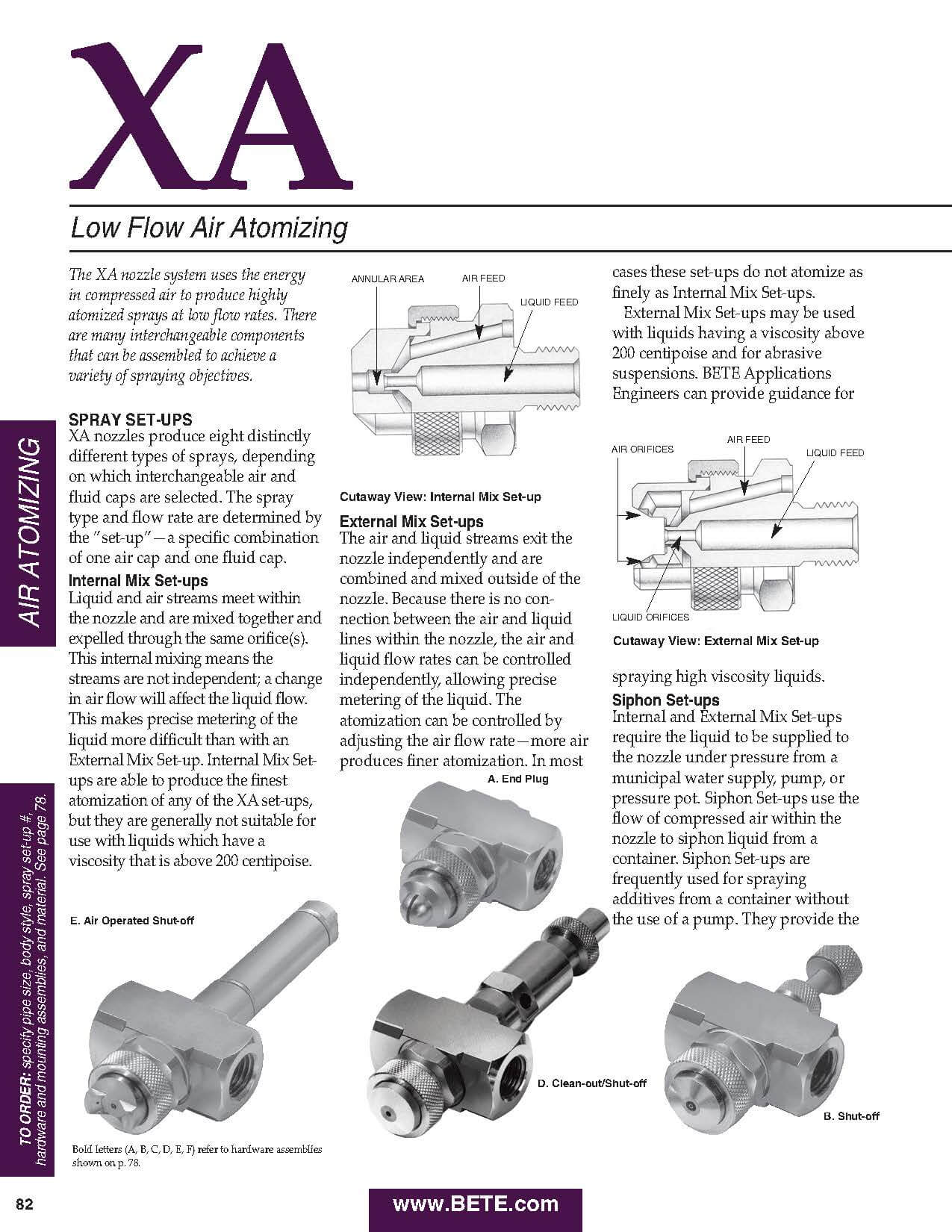

External Mix, Pressure-Fed Pneumatic Spray Nozzles

Design Features of BETE XAER Air Atomizing Spray Nozzles

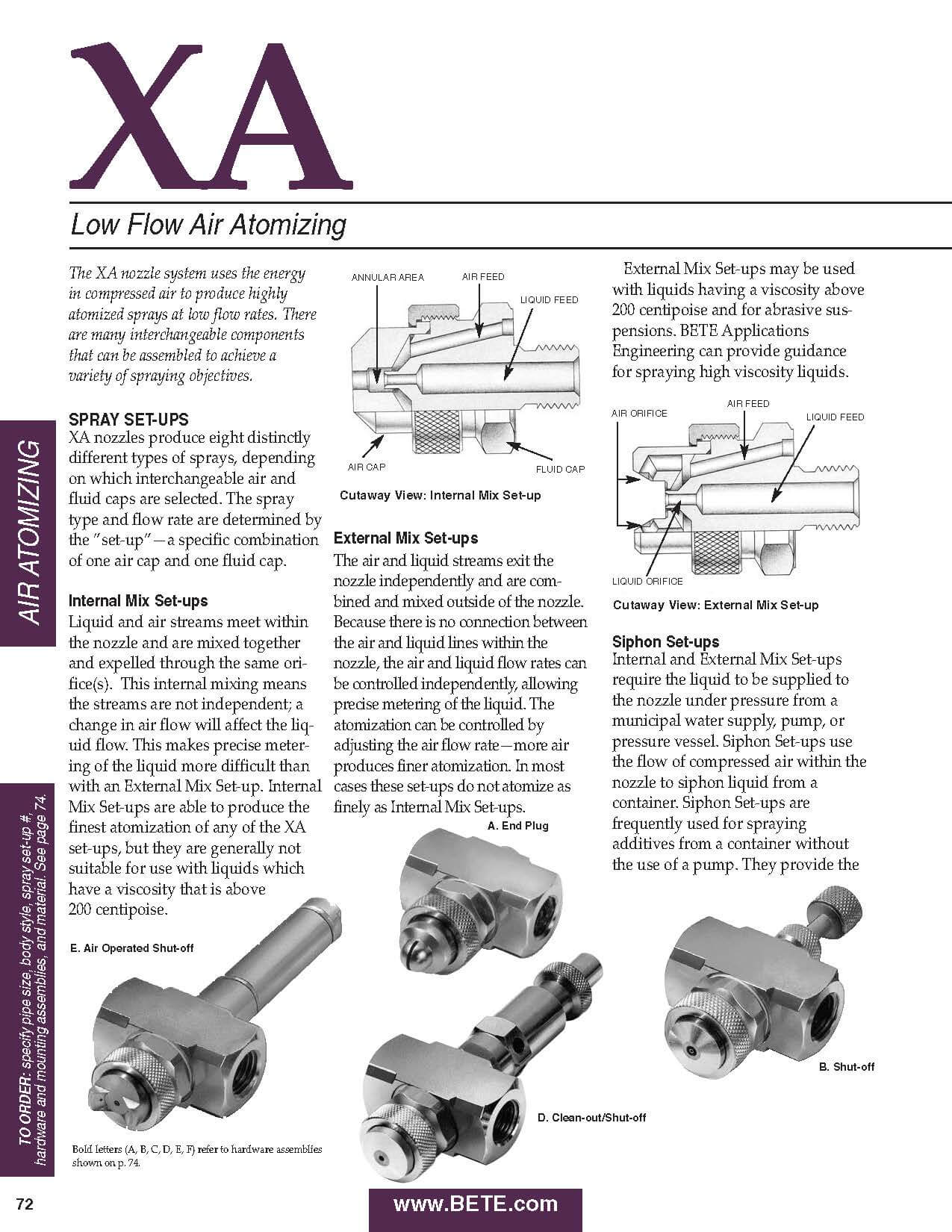

- External mix allows for the spraying of viscous materials, and

- Flow rates are regulated by fluid pressures and are independent of air pressure making the nozzle performance easier to control

- Capable of spraying high viscosity (100+ cP) fluids that require a round spray pattern

- Varying atomization

- Narrow spray angle of 10° to 30°

- Exact metering of the liquid flow rate

Spray Nozzle Characteristics

- The round pattern of the BETE XAER spray nozzle complements the existing XAEF nozzle, which produces a flat fan spray pattern

- Operating with an external mix allows the atomization of the fluid to take place outside of the nozzle

Spray Patterns

- Full Cone

- Air Atomizing

| Available Spray Angle | Materials | Available Connection Types |

|

20° |

Nickel-plated Brass, 303, 316, Nickel-plated Brass / 304, 303 / 304 |

|

Common Applications

- Air Atomizing

- Air Conditioning

- Coating

- Concrete Curing

- Cooling: Evaporative

- Fogging

- Gas Cooling

- Humidification

- Lubrication

- Misting

- Moistening

- Odor Control

- Scrubbing: Conditioning

- Scrubbing: Dry

- Spray Drying: where the fluid pressure is typically lower and the fluid viscosities are typically higher

The versatility of this nozzle is demonstrated by one of its more unique applications; injecting a viscous liquid into a gas stream containing powder particles in order to coat the powder with the liquid.