The Vaughan Rotamix System for reliable – cost effective – mechanical hydraulic mixing – sludge tanks, digesters and other high-volume applications.

Vaughan Rotamix System Features

|

|

The Vaughan Rotamix System is exactly what it claims to be — the best mixing system available today. No more issues with conventional systems — just real cost-effective sludge mixing.

Conventional, Cost-effective Sludge Mixing Wastewater Applications

- Anaerobic Digesters

- Egg-Shaped Digesters

- Sludge Storage Tanks

- Sludge Blending Tanks

- Influent Channels

- Equalization Tanks

- Secondary Digesters

- Aerobic Digesters w/ Aeration

- Alum Sludge

- Lime Slurry Storage

- Lime Stabilization

- Anoxic Zone Mixing

- Septage Waste Haulers

- CSO Tunnels

- CSO Retention Basins

- Ground Storage Tanks

- Biogas Applications

What Makes the Vaughan Rotamix System Different

Nobody else in the market can claim to have the Rotamix Systems Nozzle Assemblies and the Vaughan Chopper Pump.

The Vaughan Rotamix System Nozzle Assemblies

|

The Rotamix system uses fixed nozzle assemblies. Once the nozzle assembly is installed, the nozzles are adjusted to the factory specified angle, and permanently tightened. No additional adjustment is required.

Nozzle assemblies are offered in single and double nozzle (patent pending) configurations, depending on tank diameter and depth. All fittings are ductile cast iron and glass-lined for abrasion resistance, reduced friction, and to eliminate Struvite adhesion. The tapered nozzle barrels are 1-inch thick for long-term wear protection. The entire assembly is white metal sandblasted, and then powder coated with 3M TM Scotchkote TM Fusion Bonded Epoxy Coating, a one-part, heat-curable, thermosetting epoxy coating for superior surface protection. Each nozzle assembly includes a 10-year full warranty. |

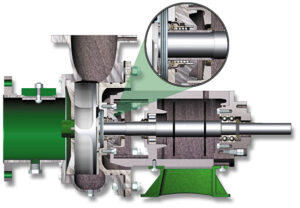

Vaughan’s chopper pump is the heart of the Rotamix system.

Vaughan’s proven technology over the past 45 years provides long-term low maintenance, and the highest reliability of any chopper pump. Continuously chopped solids not only eliminate nozzle clogging, but enhance sludge quality. Digester efficiency is increased by further reducing solids size and increasing surface contact.

Vaughan’s unique features necessary to provide this reliability include:

- Patented chopping design eliminates nozzle clogging

- Wear parts heat treated to 60+ Rockwell C Hardness extends pump life

- Oversized shafting and bearings extends pump life

- Heavy duty “flushless” mechanical seal (other seal designs available) assures leak-free operation

- Back pull-out design allows adjustment of all cutting clearances without disconnecting suction or discharge piping

Other configurations available include vertical dry pit, submersible, self-priming, vertical wet well, and recirculating pumps. All Vaughan pumps include a written Performance Guarantee, your assurance of clog-free pump operation.

Fluid Dynamics Software

Computational Fluid Dynamics

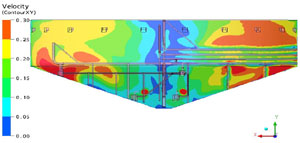

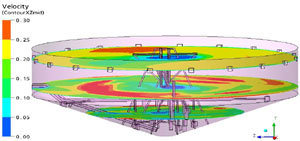

The CFD (Computational Fluid Dynamics) software used at Vaughan Co., Inc. for analysis is among the top programs available in the world for this type of detailed computer flow modeling work. The problem is solved using techniques similar to finite element stress analysis. Essentially, the fluid volume is broken down into hundreds of thousands of volume elements to be analyzed. Final results can be plotted in various formats including vector, velocity and streamline, on various tank configurations including cylindrical, rectangular and oval.

All Rotamix designs are supported by CFD analysis, either by standard modeled geometries, or using customized models individualized to meet specific application parameters on a consultation basis.

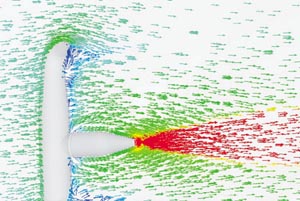

Vector Plots

|

Vector plots use arrows to show direction of fluid flow, verifying flow patterns as well as velocities. Vector plots also show flow patterns and velocities around objects such as support columns, verifying ability to mix while predicting potential “dead spots”. |

Velocity Plots

|

Velocity plots show variations in velocity as blended solid colors. Velocity plots have proven that small diameter nozzles producing high velocity provide more complete mixing than larger diameter low-velocity nozzle designs using equal amounts of energy. Higher velocity allows flow patterns to travel farther, while inducing significantly more entrained fluid.

In a theoretical comparison, larger-diameter low-velocity nozzles would be required if used with standard non-clog pumps, in an attempt to keep from plugging the nozzle openings with whole solids. |

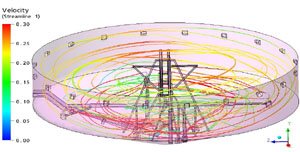

Streamline Plots

|

Streamline plots predict the path of flow for a particle starting at any given point. The plotted path shows the actual movement of the particle around the tank, confirming both horizontal and vertical movement within the mixing pattern. |

|

This image shows a streamline plot for a particle at steady state (a period of time determined long enough to create a steady state of mixing within the tank). This plot proves not only that the rotational mixing has both horizontal and vertical movement, but also that a vertical-axis vortex is created. |