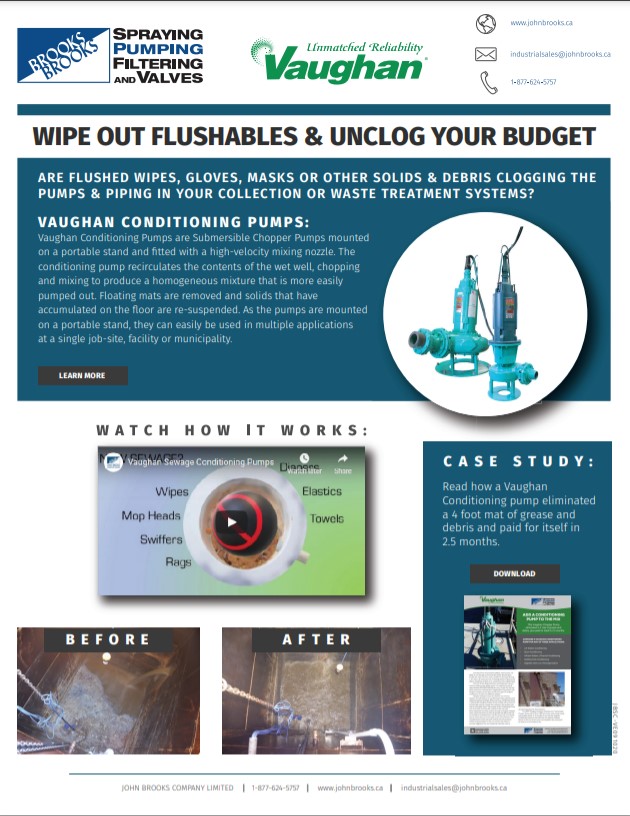

Vaughan Conditioning Pump Trial - Test before you Invest!

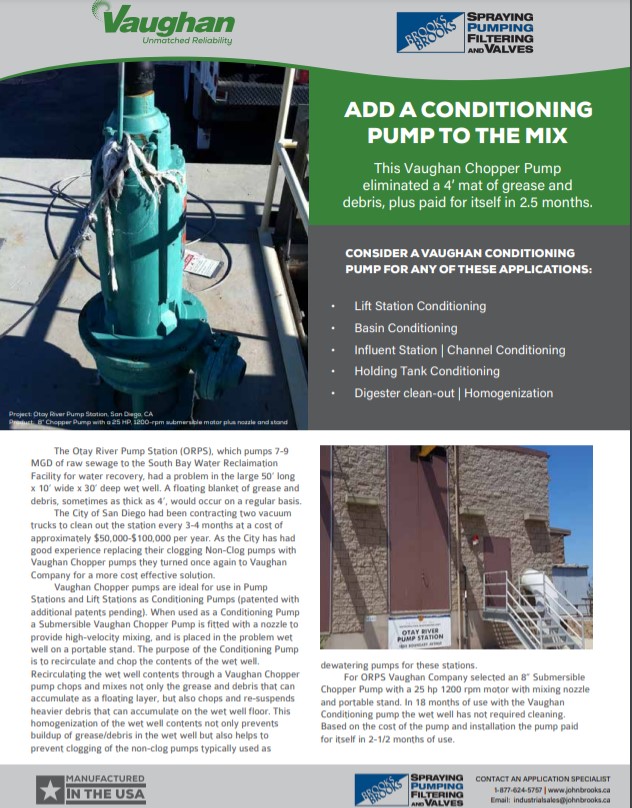

The Vaughan Conditioning Pump has proven to pay for itself in 2.5 months.

Vaughan developed the Conditioning Pump with versatility, allowing it to be used in various scenarios to prevent expensive cleaning cycles and maintenance requirements.

Save Money with the Vaughan Conditioning Pump by:

- Reducing Vacuum Truck Visits.

- Preventing existing pumps from clogging.

- Eliminating unnecessary third party cleaning cycles and unwanted costs.

- Re-suspending solids on tank floors allows duty pumps to pump and remove solids.

Elevate Your Operations with Vaughan Conditioning Pumps

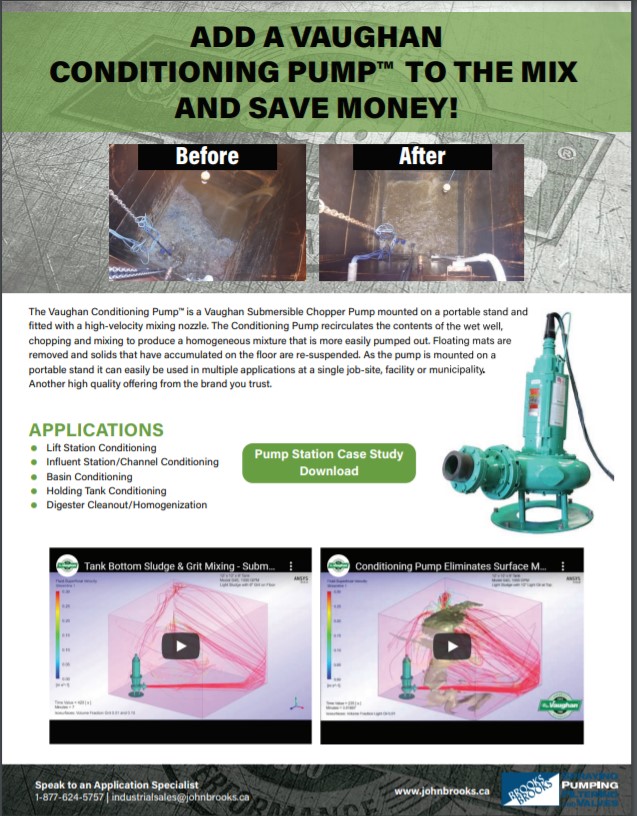

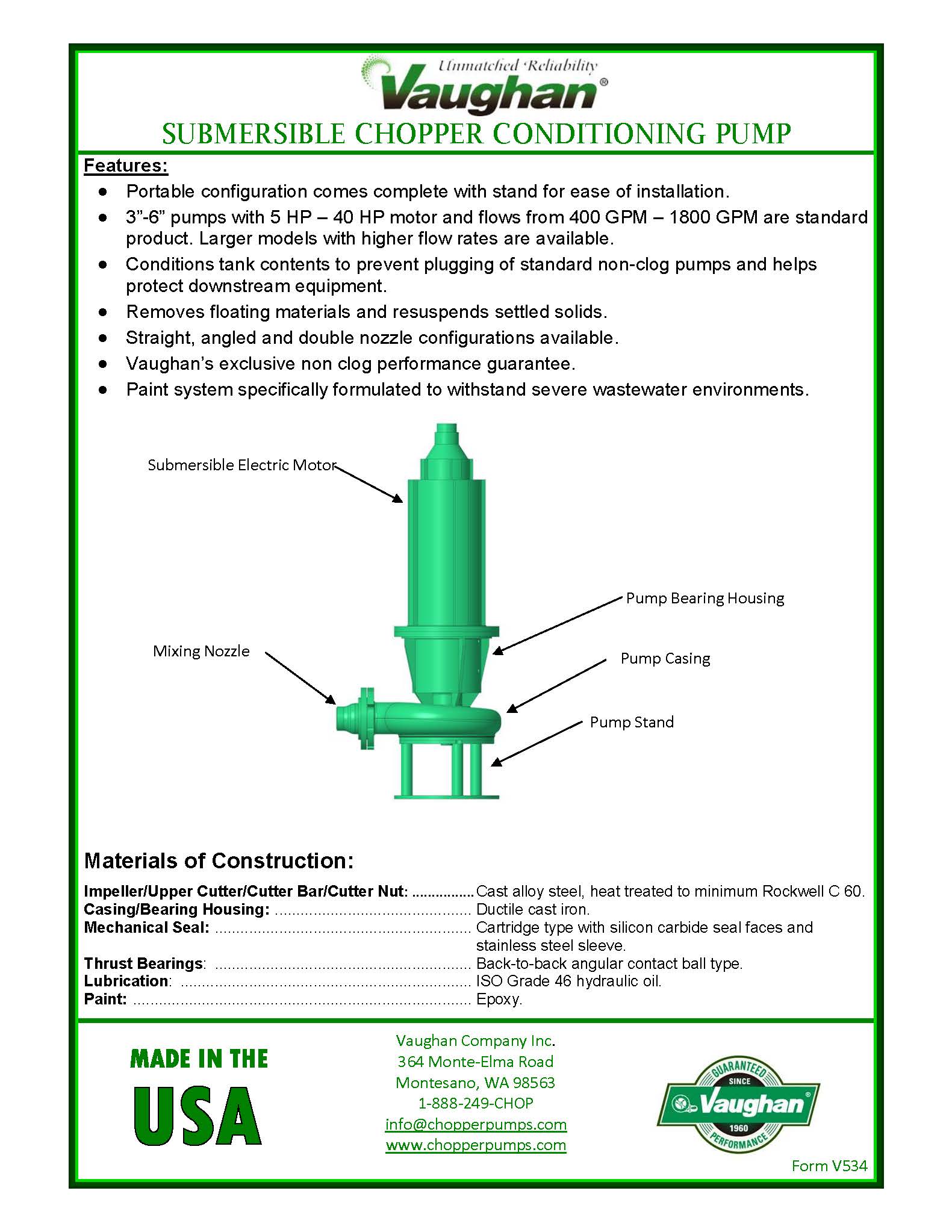

Vaughan Conditioning Pumps are Submersible Chopper Pumps, mounted on a portable stand and equipped with a high-velocity mixing nozzle, are designed for wet well applications. The Conditioning Pump takes wet well mixing to the next level, ensuring efficient chopping and mixing, resulting in a homogeneous mixture that's easily pumped out. With Vaughan Conditioning Pumps, floating mats are efficiently removed, and accumulated solids on the floor are expertly re-suspended.

The versatility of Vaughan Conditioning Pumps extends to their portability, allowing them to be applied across various scenarios within a single job site, facility, or municipality.

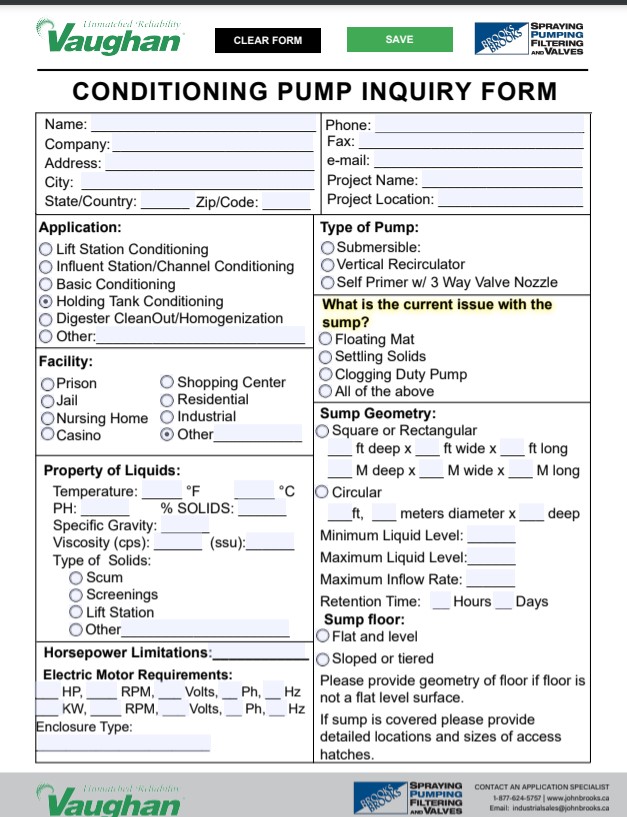

|

|

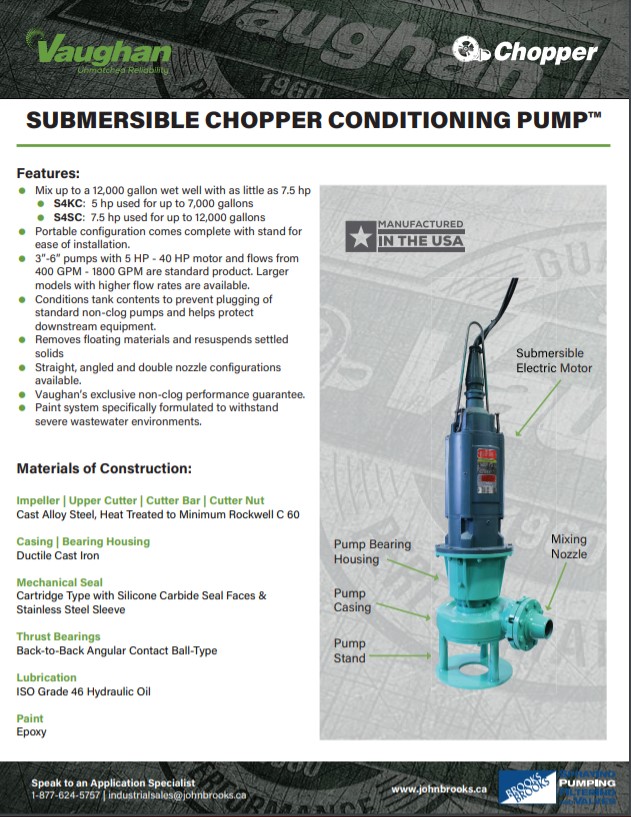

Materials of Construction

Impeller | Upper Cutter | Cutter Bar | Cutter Nut

Cast Alloy Steel, Heat Treated to Minimum Rockwell C 60

Casing | Bearing Housing

Ductile Cast Iron

Mechanical Seal

Cartridge Type with Silicone Carbide Seal Faces & Stainless Steel Sleeve

Thrust Bearings

Back-to-Back Angular Contact Ball-Type

Lubrication

ISO Grade 46 Hydraulic Oil

Paint

Epoxy

Vaughan Conditioning Pump Videos

| Tank Bottom Sludge & Grit Mixing – Submersible Pump

CFD animation demonstrating how a 6 inch layer of grit buildup on a tank floor is suspended, mixed, and homogenized in minutes. Streamlines indicate fluid paths, demonstrating complete tank mixing using a Recirculating Submersible CHOPPER Pump (Tank Size: 12x12x9′). |

|

Vaughan Conditioning Pump Eliminates Surface Matting This CFD animation demonstrates how a Vaughan submersible “S4S” Conditioning (Chopper) Pump can mix a 12” layer of oil or surface matting into a 12’ x 12’ x 09’ tank in five minutes. Conditioning Pumps provide an extra level of treatment to any wastewater system by “conditioning” the contents of a pit before the solids are transferred to another location. The Conditioning Pump utilizes a nozzle and portable-stand design that allows the unit to be moved from pit to pit as needed. Once the Conditioning Pump is lowered into a reception pit, it goes to work to reduce solids sizes, keep particles suspended, and emulsify any stratosphied layers. The Conditioning Pump is perfect for Fats, Oils, and Greases (FOG) applications or any process that requires a uniform mix. Other applications include hospital waste reception pits, prisons, waterparks, industrial sites, big box stores, etc. |