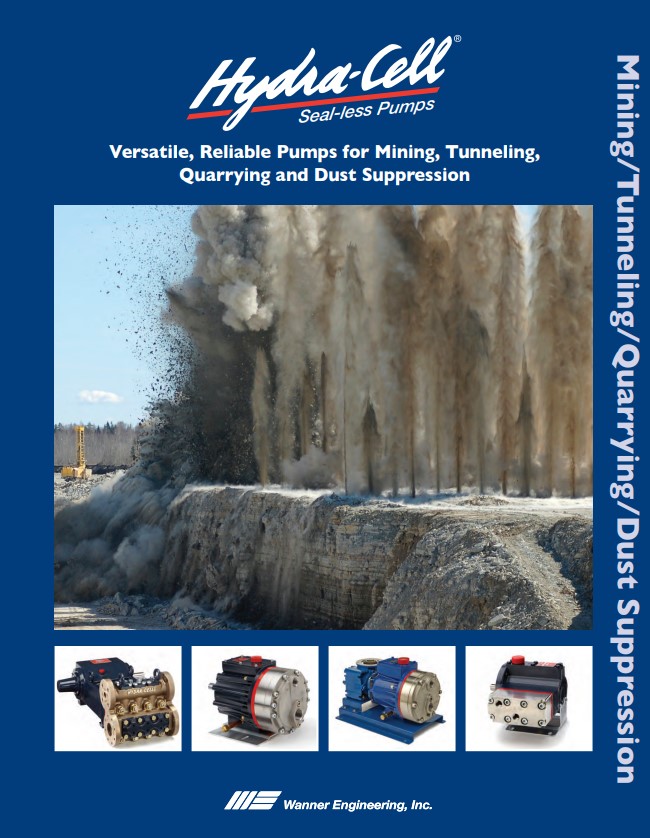

Mining, Tunneling & Quarrying

Whether pumping aggressive chemicals, drilling fluids, grouting slurries, water, or other challenging liquids, Hydra-Cell Seal-less pumps have the versatility to meet a wide range of industry applications.

- Borehole Stabilization (Injecting bentonite and other substances)

- Liquid Explosives (Charging liquid explosives into blast holes and rigs)

- Drill Head Cooling (Cooling the picks and coal cutters and tunneling machines while reducing dust generation)

- Hazardous Chemical Pumping (Metering hazardous solutions in metal extraction)

- Conveyor Cleaning (24/7 continuous duty in high-pressure jet cleaning)

- Gland Seal Flushing (Protecting large slurry pumps from seal damage)

- Gas Extraction (Powering a Venturi jet pump to lift drill hole water and release gas to the surface)

Hydra-Cell Performance Advantages Compared to Other types of Pumping Technologies

- Variety of models in a wide range of flow capacities and pressure ratings—plus an extensive choice in materials of construction—make Hydra-Cell ideally suited to many applications in the industry.

- Accurate and easy to control because the flow rate is proportional to the pump speed.

- Pumps the full spectrum of low-to-high-viscosity fluids.

- Handles abrasive solids up to 800 microns in size depending on pump model.

- Seal-less design minimizes maintenance and downtime because there are no mechanical seals, cups, or packing to leak, replace, or adjust.

- Operational efficiencies reduce energy costs.

- Tolerates non-ideal operating conditions.

- Can run dry indefinitely without damage (or additional maintenance) to the pump in case of accident or operator error.

- Hydraulically balanced diaphragm design for long life.

- Metering pump models are designed to exceed API 675 performance standards and provide smooth, linear, virtually pulse-free flow without the use of expensive pulsation dampeners.

Dust Suppression

Dust-filled air can cause discomfort for people living and working near quarries, and it can produce other forms of contamination. Fugitive dust created when crushing or transporting bulk materials can be controlled at its source by spraying very fine water droplets on the dust. This provides environmental protection and can help operators comply with safety codes and standards.

Hydra-Cell pumps are an ideal way to bring down the cost of dust suppression. High-pressure pump models power fugitive dust suppression and water fogging systems without the use of costly compressed air systems. The efficient and accurate operation of Hydra-Cell pumps also minimizes water usage and ensures a drier working environment.

Hydra-Cell pumps water or latex emulsions for airless spray in many types of installations:

- Cutting / Quarry Faces

- Crusher Stations

- Mills / Pulverizers

- Conveyor Belt Transfer Points

- Screens / Sieves

- Tips

|

|

|

|

| F/M/D/H Series Pumps | T Series Pumps | Q Series Pumps | Hydra-Cell Metering Solutions Pumps |

| Maximum flow rates from 1.0 to 65.7 gpm (3.8 to 248.7 l/min) | Maximum flow rates from 26 to 96 gpm (98.4 to 366.1 l/min) and pressure ratings from 1500 to 5000 psi (103 to 345 bar) | Maximum flow rates from 78 to 157 gpm (295 to 595 l/min) and pressure ratings from 1500 to 4500 psi (103 to 310 bar) | Maximum flow rates from to 8 to 890 gph |

Have a Fluid Handling Problem? We can help you find a Pumping Solution.

John Brooks Company caters to diverse industries, offering suitable pump solutions for nearly all fluid handling needs - including yours! Our success hinges on fostering a collaborative partnership with you, where we help you find a tailored solution to enhance your systems, boost productivity, and minimize operational expenses

Consult with a John Brooks Company Pump expert today to help you determine the most suitable pump type for your application needs.