Hydra-Cell Sealless Pump Overview & Selection

________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________

|

|

|

| T Series | Q Series |

________________________________________________________________________________________________________________________

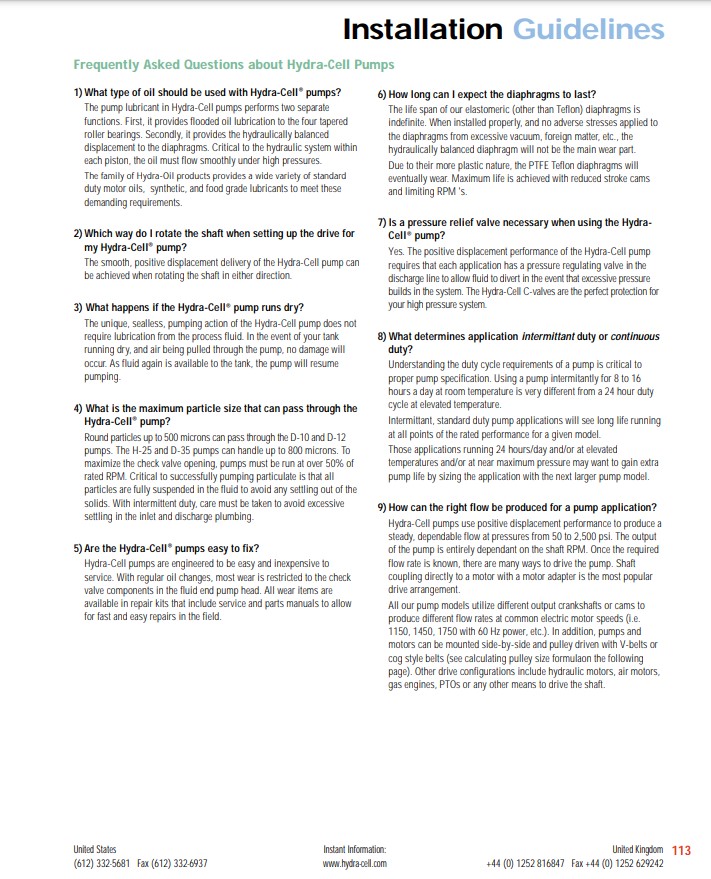

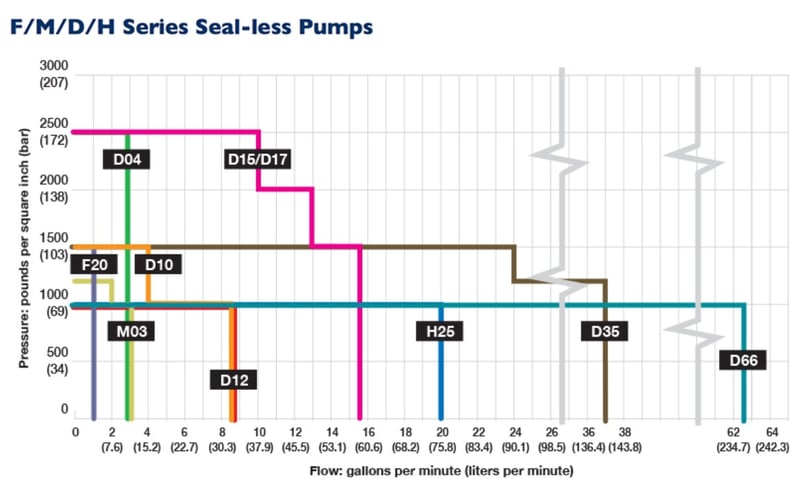

Hydra-Cell Flow Capacities and Pressure Rating

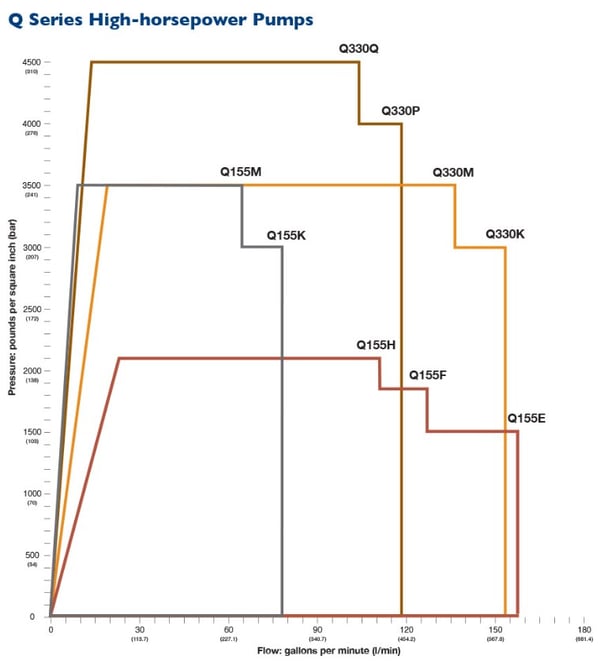

For initial Sealless Pump selection, use this chart below and click on the sealless pump model with the appropriate flow and pressure values to meet your application.

Design Considerations for Sealless Pumps

The graph above displays the maximum flow capacity at a given pressure for each model series. The table below lists the maximum flow capacity and maximum pressure capability of each model series.

Please Note: Some models do not achieve maximum flow at maximum pressure. Refer to the individual model specifications in this section for precise flow and pressure capabilities by specific pump configuration.

| Maximum Capacity gpm (l/min) | Maximum Discharge Pressure psi (bar) | Maximum Operating Temperature F (C)** | Maximum Inlet Pressure psi (bar) | |||

| Model | Non-metallic* | Metallic | Non-metallic | Metallic | ||

| F20 | 1.0 (3.8) | 350 (24) | 1500 (103) | 140º (60º) | 250º (121º) | 250 (17) |

| M03 | 3.1 (11.7) | 350 (24) | 1200 (83) | 140º (60º) | 250º (121º) | 250 (17) |

| D04 | 2.9 (11.2) | N/A | 2500 (172) | N/A | 250º (121º) | 500 (34) |

| D10 | 8.8 (33.4) | 350 (24) | 1500 (103) | 140º (60º) | 250º (121º) | 250 (17) |

| D12 | 8.8 (33.4) | N/A | 1000 (69) | N/A | 250º (121º) | 250 (17) |

| D15 & D17 | 15.5 (58.7) | N/A | 2500 (172) | N/A | 250º (121º) | 500 (34) |

| H25 | 20.0 (75.9) | 350 (24) | 1000 (69) | 140º (60º) | 250º (121º) | 250 (17) |

| D35 | 36.5 (138) | N/A | 1500 (103) | N/A | 250º (121º) | 500 (34) |

| D66 | 62.5 (236.6) | 250 (17) | 1000 (69) | 120º (49º) | 200º (93.3º) | 250 (17) *** |

* 350 psi (24 bar) maximum with PVDF liquid end; 250 psi (17 bar) maximum with Polypropylene liquid end.

** Consult factory for correct component selection for temperatures from 160 ̊F (71 ̊C) to 250 ̊F (121 ̊C).

*** 50 PSI (3.4 Bar) for non-metallic.

________________________________________________________________________________________________________________________

| Maximum Capacity | Maximum Discharge Pressure | Maximum Inlet Pressure | Maximum Operating Temperature | |||||

| Model | (gpm) | (l/min) | (psi) | (bar) | (psi) | (bar) | (F)* | (C)* |

| T100E | 96 | 366.1 | 1500 | 103 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| T100F | 76.5 | 289.6 | 1850 | 128 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| T100H | 68 | 257.8 | 2100 | 145 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| T100K | 45 | 170.4 | 3000 | 207 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| T100M | 38 | 143.8 | 3500 | 241 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| T100S | 26 | 98.4 | 5000 | 345 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| T200K | 93 | 352 | 3000 | 207 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| T200M | 83 | 314 | 3500 | 241 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| T200P | 72 | 272 | 4000 | 276 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| T200Q | 63 | 238 | 4500 | 310 | 500 | 34 | 180 ̊ | 82.2 ̊ |

* Consult factory for correct component selection for temperatures above 180 ̊F (82 ̊C) or below 40 ̊F (4 ̊C)

________________________________________________________________________________________________________________________

| Maximum Capacity | Maximum Discharge Pressure | Maximum Inlet Pressure | Maximum Operating Temperature | |||||

| Model | (gpm) | (l/min) | (psi) | (bar) | (psi) | (bar) | (F)* | (C)* |

| Q155E | 157 | 595 | 1500 | 103 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| Q155F | 127 | 490 | 1850 | 128 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| Q155H | 111 | 421 | 2100 | 145 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| Q155K | 78 | 295 | 3000 | 207 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| Q155M | 63 | 238 | 3500 | 241 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| Q330K | 153 | 579 | 3000 | 207 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| Q330M | 136 | 514 | 3500 | 241 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| Q330P | 118 | 446 | 4000 | 276 | 500 | 34 | 180 ̊ | 82.2 ̊ |

| Q330Q | 104 | 393 | 4500 | 310 | 500 | 34 | 180 ̊ | 82.2 ̊ |

* Consult factory for correct component selection for temperatures above 180 ̊F (82 ̊C) or below 40 ̊F (4 ̊C)

________________________________________________________________________________________________________________________

Hydra-Cell Pumps for Mining, Tunneling, Quarrying & Dust Suppression

Applications by Mining Market

- Borehole Stabilization (Injecting bentonite and other substances)

- Liquid Explosives (Charging liquid explosives into blast holes and rigs)

- Drill Head Cooling (Cooling the picks and coal cutters and tunneling machines while reducing dust generation)

- Hazardous Chemical Pumping (Metering hazardous solutions in metal extraction)

- Conveyor Cleaning (24/7 continuous duty in high-pressure jet cleaning)

- Gland Seal Flushing (Protecting large slurry pumps from seal damage)

- Gas Extraction (Powering a Venturi jet pump to lift drillhole water and release gas to the surface)

Have a Fluid Handling Problem? We can help you find a Pumping Solution.

John Brooks Company caters to diverse industries, offering suitable pump solutions for nearly all fluid handling needs - including yours! Our success hinges on fostering a collaborative partnership with you, where we help you find a tailored solution to enhance your systems, boost productivity, and minimize operational expenses

Consult with a John Brooks Company Pump expert today to help you determine the most suitable pump type for your application needs.