Lift Station Pump Clogging Eliminated

The Challenge

A municipality in Canada had a problem with “flushables” clogging their sewage pumps and negatively impacting the up-time of their sewage treatment system. The pumps were experiencing an excessive build-up of “flushable” wipes & rags, often causing damage to the impellers. These blockages resulted in extra maintenance costs for the municipality due to the need to frequently unclog the pumps. Unfortunately, this is a common issue that many municipalities face today. Flushable wipes and non-flushable items, such as masks & gloves, entering sewage systems and causing pump clogging and damage is an ever-increasing problem. This issue will worsen without an engineered solution like Eradicator Solids Management System for solids handling within sewage treatment systems.

The Solution

Our application experts investigated the problem and recommended the Eradicator Solids Management System from Gorman-Rupp. The Eradicator system and appropriate Gorman-Rupp pumps are designed to break up the materials and guide them through the pumps more easily – essentially eliminating the blockage. This municipality had 2 Gorman-Rupp T10 pumps installed, so installing the Eradicator system onto their existing pumps was easy and straightforward. The Eradicator system helped the municipality save on service and maintenance costs and eliminate unscheduled downtime of the system. The municipality was so impressed with the results that they are upgrading all of their Gorman-Rupp Lift Stations to Eradicator Technology. For existing Gorman-Rupp Super T Series pump installations where clog-prone materials are affecting uptime and maintenance costs, the Eradicator Converter Kit is the recommended solution.

The Results

- Eliminated Clogging

- Improved Up-time

- Reduced Nuisance After Hours Service Calls & Associated Costs

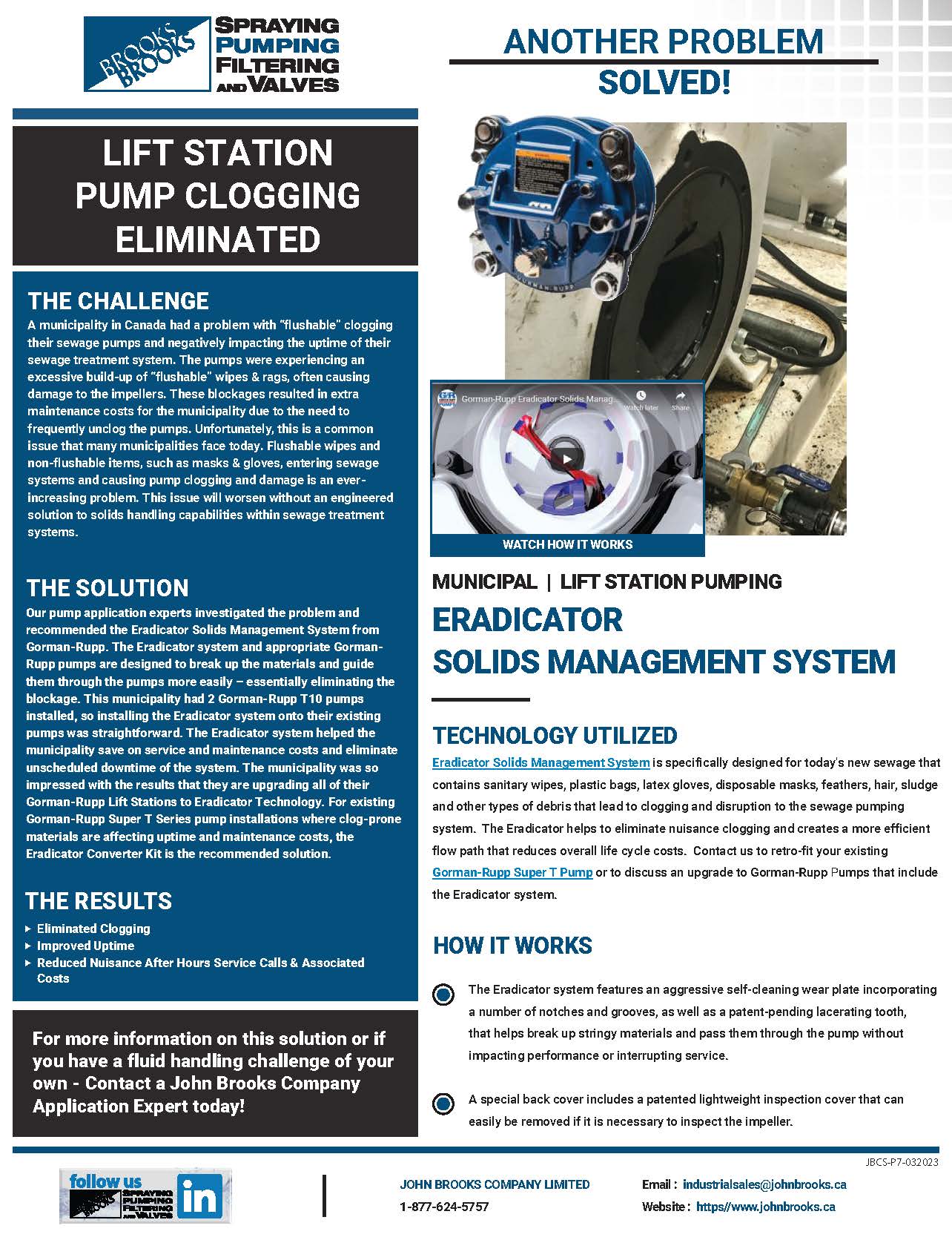

Technology Utilized

Eradicator Solids Management System is specifically designed for today’s new sewage that contains sanitary wipes, plastic bags, latex gloves, disposable masks, feathers, hair, sludge and other types of debris that lead to clogging and disruption to the sewage pumping system. The Eradicator helps to eliminate nuisance clogging and creates a more efficient flow path that reduces overall life cycle costs. Contact us to retrofit your existing Gorman-Rupp Super T Pump or to discuss an upgrade to Gorman-Rupp Pumps, including the Eradicator system.

How It Works

- The Eradicator system features an aggressive self-cleaning wear plate incorporating several notches and grooves and a patent-pending lacerating tooth that helps break up stringy materials and pass them through the pump without impacting performance or interrupting service.

- A unique back cover includes a patented lightweight inspection cover that can easily be removed if it is necessary to inspect the impeller.

Have a Pump Application Challenge? We can help you find a Pumping Solution.

John Brooks Company caters to diverse industries, offering suitable pump solutions for nearly all industrial and municipal application challenges - including yours! Our success hinges on fostering a collaborative partnership with you, where we help you find a tailored solution to enhance your systems, boost productivity, and minimize operational expenses

Consult with a John Brooks Company Pump expert today to help you determine the most suitable pump type for your pumping application needs.