Application #060532

Industry: Food Processing

Application: Tank Washing

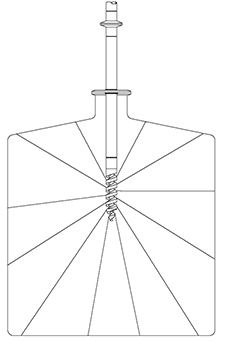

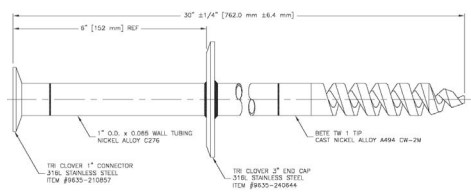

Product Description: Special Bete TW Lance with Sanitary Fittings

Situation: A food processing facility that produces various condiments was having a corrosion problem with their tank washing nozzles. The corrosion problem involved one of the very acidic, tomato-based condiments. The acidity, in addition to the 100°F (37.78°C) processing temperature and the submersion of the nozzles into the condiment resulted in the 316 stainless steel nozzles and lances succumbing to severe corrosive attack. In addition, due to the customer’s existing piping, the end solution also required Tri-Clover® sanitary fittings for the mounting flange and liquid inlet.

Solution: Because this application required a corrosion-resistant material, Bete Applications Engineers selected nickel alloy C as the material of choice to stand up to the highly acidic environment in which the nozzles and lances would be submerged. Food processing applications such as these require a smooth lance assembly profile and the Bete TW-1 tank washing nozzles were machined to special dimensions to have the same outside diameter as the tube.

Custom Spray Nozzle Solutions – Tank Washing Nozzles in Food Processing Facility Drawings and Sketches: