Clog-Resistant Compact Tank Cleaning Devices

Tank Washing and Clog Resistant Nozzle

The TW series is primarily designed to wash and rinse smaller containers such as kegs and barrels.

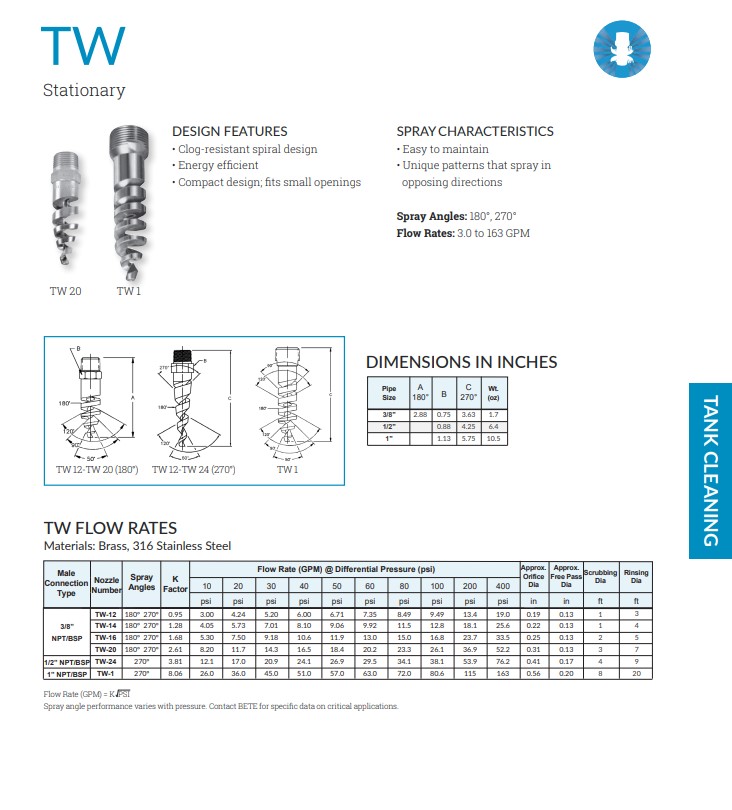

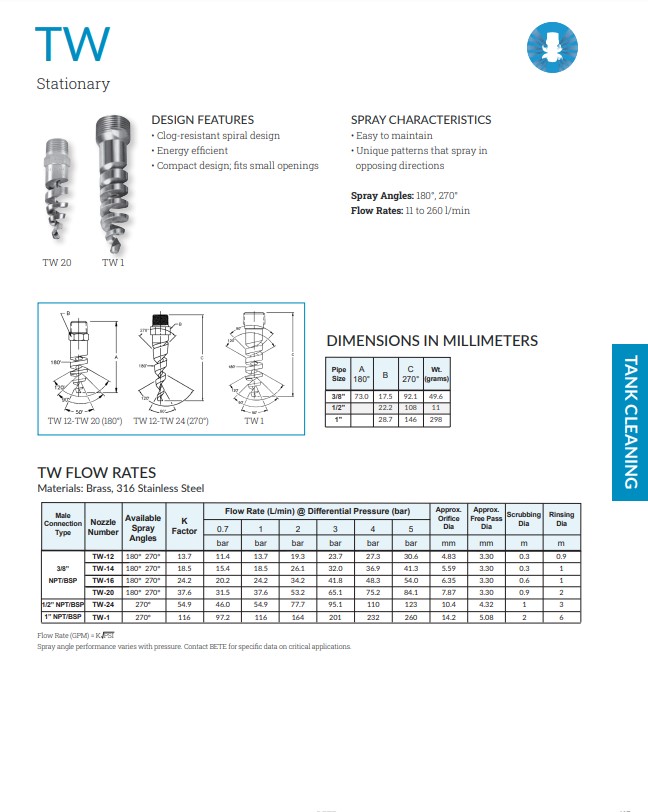

The TW12 – TW20 nozzles produce concentric spray cones of 180°, 120°, 90° and 50°. They are well suited to spraying upwards or horizontally. Like the Bete LEM they perform best at moderate pressures (10 – 30 psi, 1 – 2 bar). The TW spiral design has no internals and is a compact, clog- resistant, one- piece construction with no moving parts. These physical design attributes make it ideal for food and pharmaceutical washing environments. The TW is an excellent choice for applications requiring FDA compliance.

The TW1 is of slightly different design, delivering backward spray at 90° and 120° angles and higher flow capacity. Tank rinsing rather than scrubbing is the most appropriate application.

Design Features of the TW Tank Washing and Clog Resistant Nozzle:

– Clog-resistant spiral design

– Energy efficient; uses less water than conventional designs

– Compact design; fits small openings

Spray Characteristics of the TW Tank Washing and Clog Resistant Nozzle

– Easy to maintain

– Unique patterns that spray in opposing directions

– See Bete LEM for other tank washing applications

| Available Spray Angles | Flow Rate Range |

| 180 - 270° | 3 to 114 gpm |

| Available Connection Types | Materials |

|

Brass, 316, A494 CW2M (cast Nickel Alloy C-276) |

How Spray Pattern is Achieved

- The spray pattern of the spiral nozzle is formed by the fluid shearing along with the turns of the spiral, which produce multiple concentric cones. These cones form 2 to 3 bands of relatively coarse droplets, surrounded by wider bands of relatively fine droplets.