Custom Spray Nozzle Solutions – Storage Silo Washing

Application #060949

Industry: Plastics

Application: Tank Washing

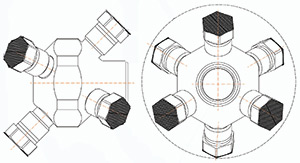

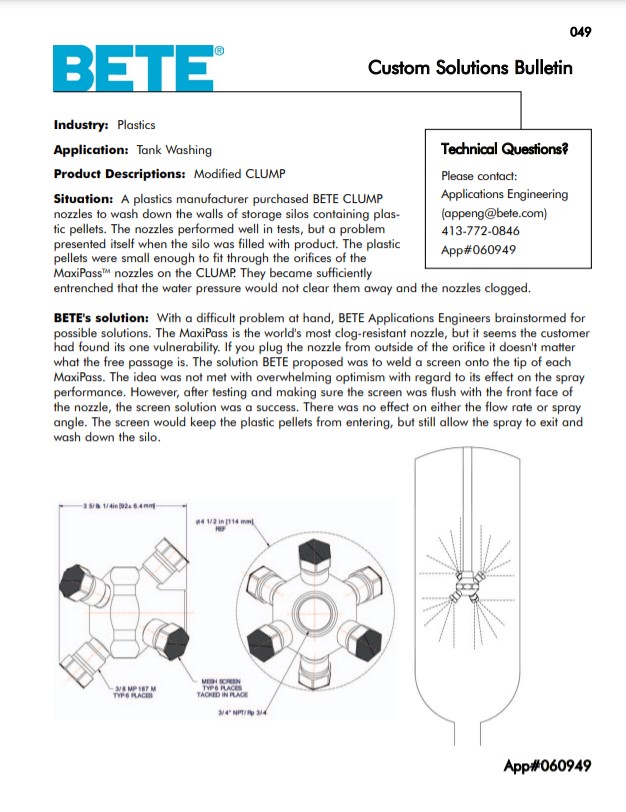

Product Description: Modified Bete CLUMP

Situation: A plastics manufacturer purchased Bete CLUMP nozzles to wash down the walls of storage silos containing plastic pellets. The nozzles performed well in tests, but a problem presented itself when the silo was filled with product. The plastic pellets were small enough to fit through the orifices of the Bete MaxiPass nozzles on the CLUMP. They became sufficiently entrenched that the water pressure would not clear them away and the nozzles clogged.

Solution: With a difficult problem at hand, Bete Applications Engineers brainstormed for possible solutions. The MaxiPass is the world’s most clog-resistant nozzle, but it seems the customer had found its one vulnerability. If you plug the nozzle from outside of the orifice it doesn’t matter what the free passage is. The solution Bete proposed was to weld a screen onto the tip of each MaxiPass. The idea was not met with overwhelming optimism with regard to its effect on the spray performance. However, after testing and making sure the screen was flush with the front face of the nozzle, the screen solution was a success. There was no effect on either the flow rate or spray angle. The screen would keep the plastic pellets from entering, but still allow the spray to exit and wash down the silo.

Custom Spray Nozzle Solutions – Storage Silo Washing Drawings and Sketches: