Clog-Resistant Stationary Tank Cleaning Devices

Tank Washing Nozzle, Drum Washing Nozzle and Bottle Washing Nozzle

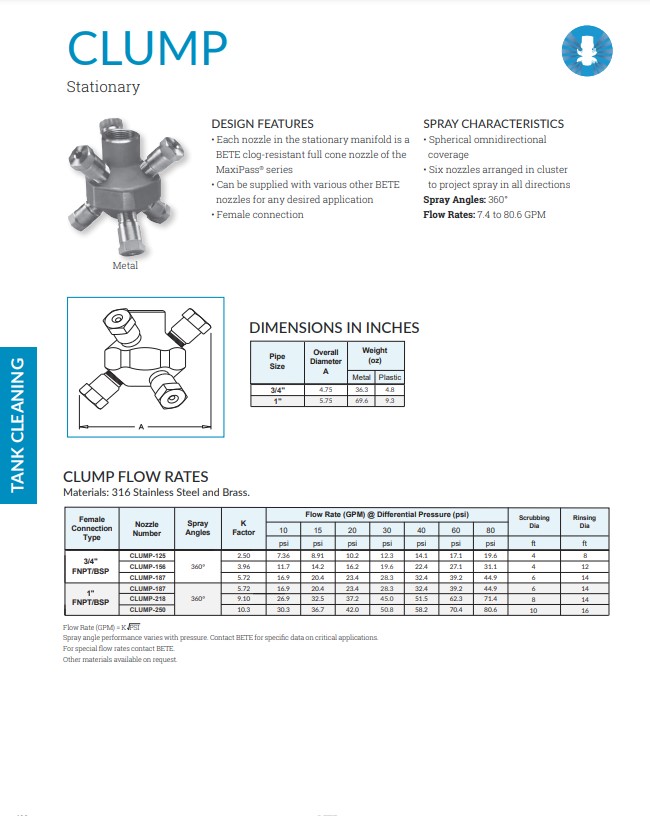

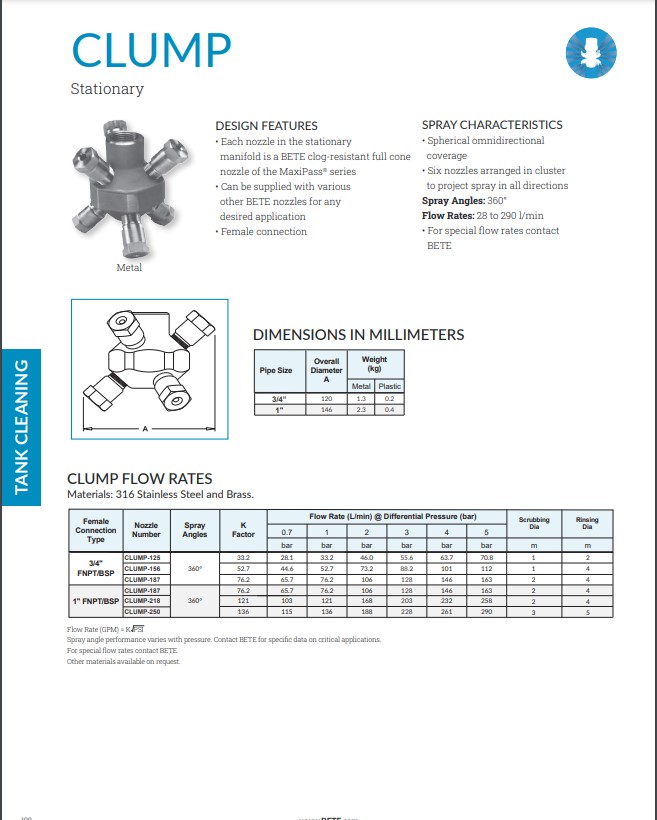

The Bete CLUMP is an assembly of Bete MaxiPass nozzles in a manifold providing omni-directional coverage similar to the Bete LEM. The CLUMP provides an even spray pattern and a larger free passage. It’s peak performance is at 10-30 psi (1-2 bar) and can fit through openings 4.75′ and 575′ (37.4mm and 146mm). Stationary nozzles, such as the CLUMP spray head, are characterized

by a particularly large cross-section. In addition, these nozzles are extremely low maintenance.

Design Features of the Bete CLUMP Spray Nozzle:

– Each tank washing nozzle in the stationary cluster is a BETE clog-resistant full cone nozzle of the MaxiPass series

– Can be supplied with various other BETE nozzles for any desired application

– Female connection

– Symmetrical spray make them more suited to short tanks, full 360° washing

– Very large free passage

– Spray nozzle heads for industrial tank cleaning, drum, and tote washing

– Six clog-resistant MaxiPass® full cone nozzles arranged in a cluster to project spray in all directions

Spray Characteristics of the Bete CLUMP Spray Nozzle:

– Spherical omnidirectional coverage

– Six nozzles arranged in cluster to project spray in all directions

Standard Materials: 316 Stainless Steel. Other materials available on request. 3/4″ CLUMP not available in PTFE

| Available Spray Angle | Flow Rate Range |

| 360° | 7.38 to 124 gpm |

| Available Connection Types | Materials |

|

Brass, 316, A494 CW2M (cast Nickel Alloy C-276) |

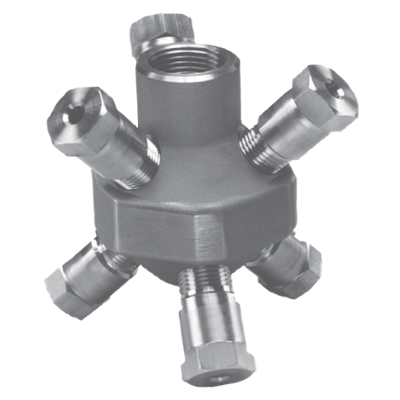

Bete CLUMP Spray Nozzle Visual:

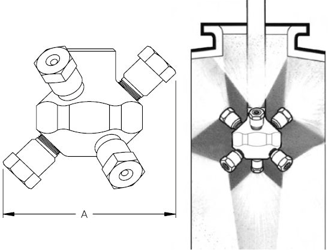

Tank Washing Nozzles:

How Spray Pattern is Achieved

- A manifold distributes water to several standard full cone nozzles with orientations positioned to achieve a full omnidirectional spray coverage