Custom Spray Nozzle Solutions – Special Tank Washing Application

Application #060476

Industry: Chemical Processing

Application: Tank Washing

Product Description: Special Kynar Bete LEM 8

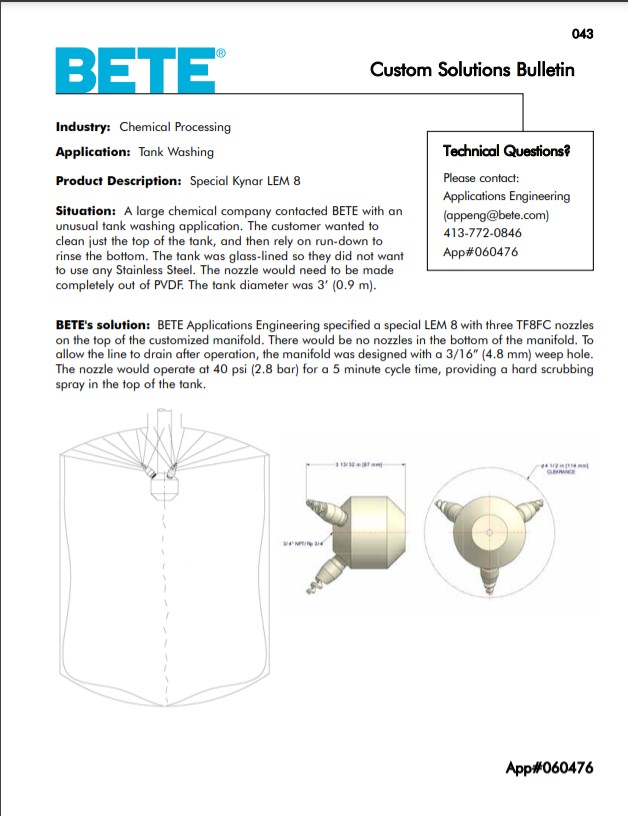

Situation: A large chemical company contacted Bete with an unusual tank washing application. The customer wanted to clean just the top of the tank, and then rely on run-down to rinse the bottom. The tank was glass-lined so they did not want to use any Stainless Steel. The nozzle would need to be made completely out of PVDF. The tank diameter was 3′ (0.9 m).

Solution: Bete Applications Engineering specified a special Bete LEM 8 with three TF8FC nozzles on the top of the customized manifold. There would be no nozzles in the bottom of the manifold. To allow the line to drain after operation, the manifold was designed with a 3/16″ (4.8 mm) weep hole. The nozzle would operate at 40 psi (2.8 bar) for a 5 minute cycle time, providing a hard scrubbing spray in the top of the tank.

Custom Spray Nozzle Solutions – Special Tank Washing Application Drawings and Sketches: