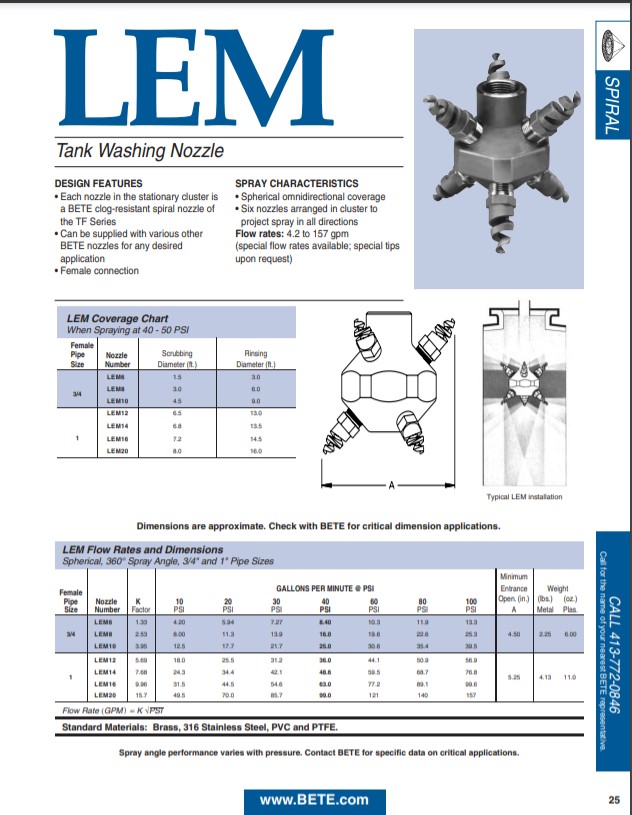

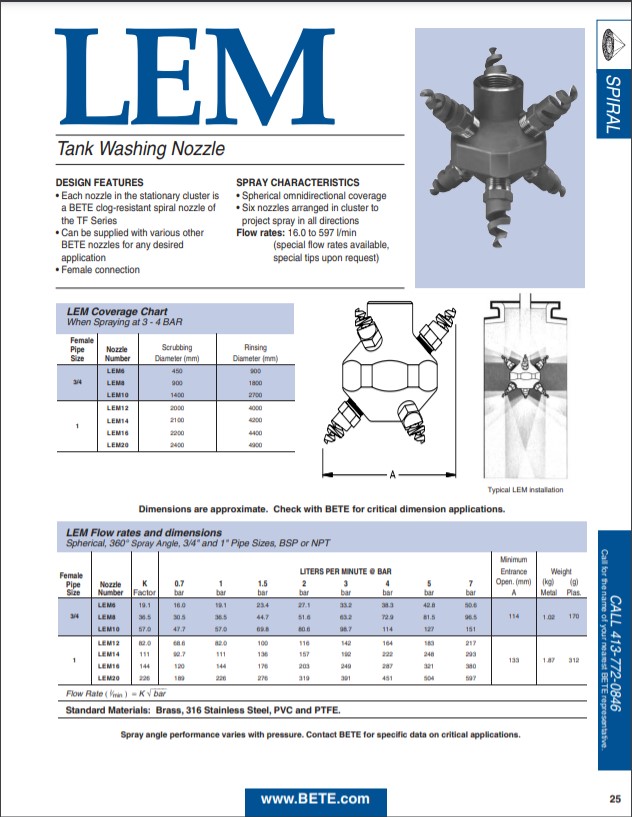

Bete LEM Spray Nozzle

Tank, Drum and Bottle Washing Nozzle

The LEM series produces an omni- directional spray. The spray is relatively low impact, with individual spray cones producing good rinsing in targeted areas. Typically the LEMs perform best at low to moderate pressures (10 – 30 psi, 1 – 2 bar, see chart). This series, as well as the Bete CLUMP series, creates symmetrical spray, “a wet puffball,” and is best suited to tanks whose width exceeds their height.

Design Features of the Bete LEM Tank, Drum, and Bottle Washing Nozzle

– Each nozzle in the stationary cluster is a BETE clog-resistant spiral nozzle of the TF series

– Can be supplied with various other BETE nozzles for any desired application

– Female connection

Spray Characteristics of the Bete LEM Tank, Drum and Bottle Washing Nozzle

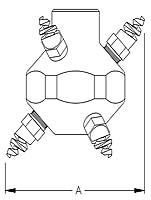

– Spherical omnidirectional coverage

– Six nozzles arranged in cluster to project spray in all directions

– Excellent for pre-wash cooling and fume absorption.

– Best rinsing performance between 10 – 30 psi (1-2 bar).

– Full 360° rinsing of moderate sized vessels (up to 16’, 4.88m dia.)

Spray Angles: 360°

Flow rates: 4.2 to 157 gpm (16.0 to 597 L/min)

Standard Materials: Brass, 316 Stainless Steel, PVC and PTFE.

.jpg)