Custom Spray Nozzle Solutions – Smoke Stack Gas Cooling

Application #071049

Industry: Marine Pollution Control

Application: Smoke Stack Gas Cooling

Product Description: 1/4″ Bete L40 Nozzle

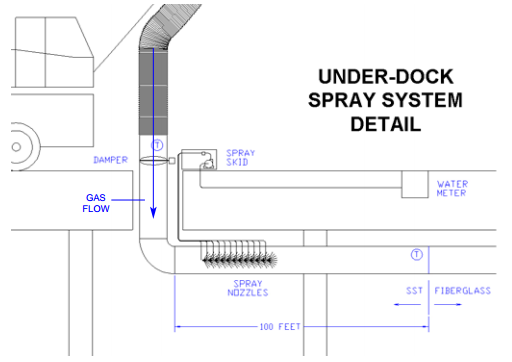

Situation: An engineering firm contacted Bete requesting nozzles for a gas cooling process. Their system was put in place over ship’s smokestacks as they came into port to capture and treat the exhaust gases. The exhaust gases needed to be cooled from 600°F to 300°F (316°C to 149°C) before it entered the fiberglass section of ducting. There is 100 ft (30.5 m) of straight ducting to construct a quench length, which is located under the dock. The quench length was requested to be as short as possible. Other concerns expressed by the company were of varying inlet gas temperatures, gas flows, and periodic maintenance.

Solution: A nozzle was selected using the worst-case conditions and a quench length of 20 ft (6.1 m). Bete Applications Engineers recommended that the nozzles be grouped in “stages” of 3 or 4 nozzles that would allow the system to be kept at a constant water pressure. Depending on the conditions of the gas, a stage could be turned off or on to decrease or increase the water flow rate. The other concern was that the nozzles had to be mounted under the dock in the 100 ft (30.5 m) of ducting. Because the quench length was only 20 ft, it was concluded that the nozzles could be moved to a section above the dock that provided access for easier maintenance.

Custom Spray Nozzle Solutions – Smoke Stack Gas Cooling Drawings and Sketches: