Custom Spray Nozzle Solutions – Rapid Cooling Using Liquid Nitrogen

Application #071524

Industry: Food Processing

Application: Rapid Cooling Using Liquid Nitrogen

Product Description: 1/4″ Bete L 40 Nozzles in Stainless Steel

Situation: A beverage company contacted Bete with an unusual and engaging application. The innovating company wanted to rapidly cool a 15% alcohol, 85% water solution by spraying liquid nitrogen through the mixture from the bottom of the tank. Bete Applications Engineers were sought out directly for their extensive experience in such interrelated fields.

Solution: While spraying cryogenic liquids to cool an area is not uncommon, spraying into an alcoholic beverage is. And while the primary concerns in such applications are similar, the results of the latter can be much more palatable. Typically spiral-type nozzles are used for their fine atomization and inherent “self-cleaning” characteristics. Any possible clogs from water condensing and freezing on the nozzle are generally washed out by upstream liquid nitrogen. These considerations become even more critical when a nozzle is immersed in the brew.

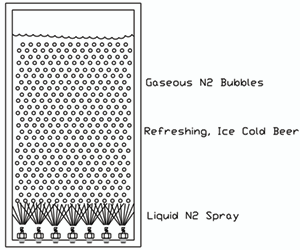

Since the liquid nitrogen may boil on contact with the alcohol mixture and the alcohol mixture may freeze on contact with the liquid nitrogen, and the two fluids have fairly similar densities, the spray pattern was hard to predict. However, nitrogen bubbles were expected to rise through and cool the beverage. To maximize this beverage/liquid nitrogen interaction, an array of ten Bete L 40 nozzles was proposed. The low flow rate of the L nozzles optimizes the use of liquid nitrogen while providing the benefits of the spiral design. Stainless steel was chosen as the material of construction for its general durability in such vital applications.

Custom Spray Nozzle Solutions – Rapid Cooling Using Liquid Nitrogen Drawings and Sketches: