Custom Spray Nozzle Solutions – Light Cycle Oil Quench

Application #020552

Industry: Petroleum

Application: Light Cycle Oil (LCO) Quench

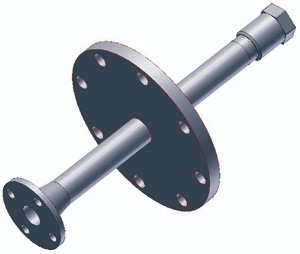

Product Description: Special Bete MaxiPass Lance

Situation: A customer came to Bete looking for a nozzle that would spray light cycle oil (LCO) and steam to quench a hydrocarbon gas stream entering an FCC riser. The purpose of the steam was to achieve finer atomization than would be achieved with LCO only.

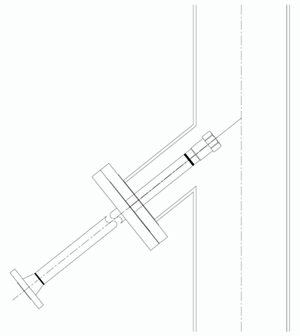

Solution: The material of choice for the MaxiPass 656N was AMS-5387 (Cobalt Alloy 6) because of the erosive nature of the stream into which it was spraying. In this case the nozzle was to be welded to a 304H stainless steel lance. The nozzle was to be fed with a 1-1/2 inch 300# ANSI flange. Because the lance needed to meet x-ray weld standards, the inlet flange had to be a weld neck style flange. Bete welders used their years of experience to perform the challenge of the 304H to cobalt alloy 6 weld, the feed flange to pipe weld, and the mounting flange weld. The mounting flange was a 6 inch raised face flange to mate with the existing stub end already on the riser. The MaxiPass nozzle is an ideal choice for LCO-steam (two-phase) applications because of its internal S-shaped vane that not only ensures a homogeneous LCO-steam mixture, but an even distribution of the mixture as well. The Bete MaxiPass series is a proven performer in LCO-steam applications.

Custom Spray Nozzle Solutions – Light Cycle Oil Quench Drawings and Sketches: