Custom Spray Nozzle Solutions – Injection of Water into Engine Manifold

Application #040943

Industry: Automotive

Application: Injection of Water into Engine Manifold

Product Description: Wall-mounted Bete L Nozzle

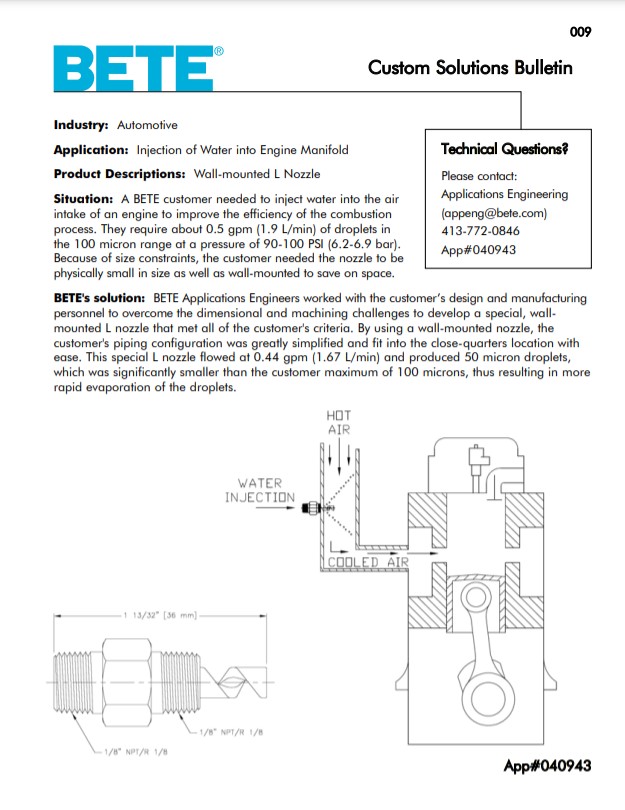

Situation: A BETE customer needed to inject water into the air intake of an engine to improve the efficiency of the combustion process. They require about 0.5 gpm (1.9 L/min) of droplets in the 100 micron range at a pressure of 90-100 PSI (6.2-6.9 bar). Because of size constraints, the customer needed the nozzle to be physically small in size as well as wall-mounted to save on space.

Solution: BETE Applications Engineers worked with the customer’s design and manufacturing personnel to overcome the dimensional and machining challenges to develop a special, wall-mounted L nozzle that met all of the customer’s criteria. By using a wall-mounted nozzle, the customer’s piping configuration was greatly simplified and fit into the close-quarters location with ease. This special L nozzle flowed at 0.44 gpm (1.67 L/min) and produced 50 micron droplets, which was significantly smaller than the customer maximum of 100 microns, thus resulting in more rapid evaporation of the droplets.

Product Information: The Bete L spray nozzle is a series of low flow spiral nozzles with flow rates 0.14 to 3.84 gpm (0.53 to 14.5 L/min). It also has higher flow than the Bete PJ with fine atomization. The Bete L nozzle can produce high flow misting performance (very fine hollow cone fog) at low pressure.

Custom Spray Nozzle Solutions – Injection of Water into Engine Manifold Drawings and Sketches: