Custom Spray Nozzle Solutions – Gas Cooling and Cleaning

Application #050994

Industry: Steel

Application: Gas Cooling

Product Description: Titanium Lance with Multiple Bete Twist & Dry nozzles

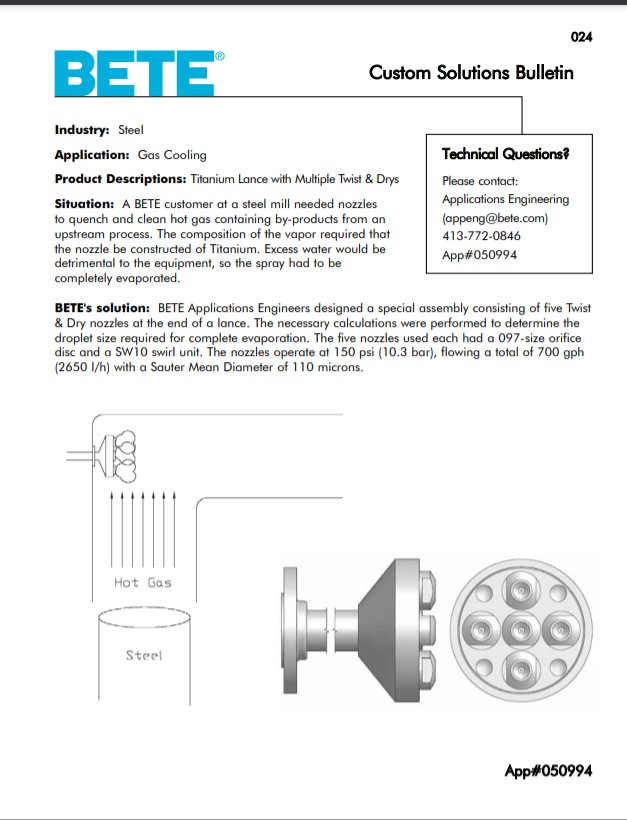

Situation: A Bete customer at a steel mill needed nozzles to quench and clean hot gas containing by-products from an upstream process. The composition of the vapor required that the nozzle be constructed of Titanium. Excess water would be detrimental to the equipment, so the spray had to be completely evaporated.

Solution: Bete Applications Engineers designed a special assembly consisting of five Twist & Dry nozzles at the end of a lance. The necessary calculations were performed to determine the droplet size required for complete evaporation. The five nozzles used each had a 097-size orifice disc and a SW10 swirl unit. The nozzles operate at 150 psi (10.3 bar), flowing a total of 700 gph (2650 l/h) with a Sauter Mean Diameter of 110 microns.

Custom Spray Nozzle Solutions – Gas Cooling and Cleaning Drawings and Sketches: