Custom Spray Nozzle Solutions – Foam Control

Application #041756

Industry: Petroleum Processing

Application: Foam Control

Product Description: Bete MaxiPass (MP) Nozzle Array

Situation: A customer had process condensate wastewater in a petroleum processing facility. The wastewater was in a square tank that measured 10′ x 11′ by 9′ (3m x 3.4m x 2.7m) deep. As the wastewater entered the tank, foam was being generated which was undesirable in this process. The customer had about 25 gpm (94.6 L/min) available to use to control the foam. In addition, the customer was looking for a turnkey system that could be installed as soon as it arrived on site.

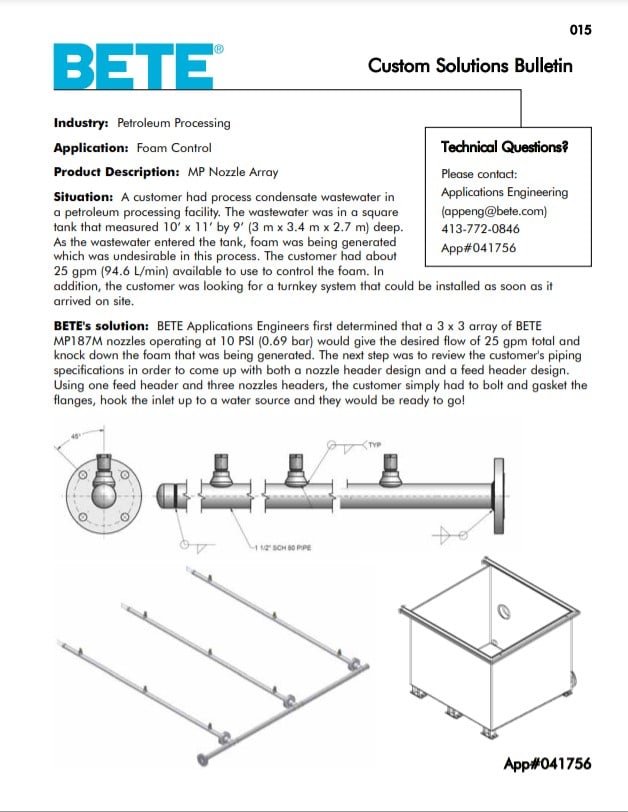

Solution: Bete Applications Engineers first determined that a 3 x 3 array of Bete MP187M nozzles operating at 10 PSI (0.69 bar) would give the desired flow of 25 gpm total and knock down the foam that was being generated. The next step was to review the customer’s piping specifications in order to come up with both a nozzle header design and a feed header design. Using one feed header and three nozzles headers, the customer simply had to bolt and gasket the flanges, hook the inlet up to a water source and they would be ready to go!

Custom Spray Nozzle Solutions – Foam Control Drawings and Sketches:

.jpg)