Custom Spray Nozzle Solutions – Ethanol Making Process

Application #061969

Industry: Ethanol

Application: Material Injection

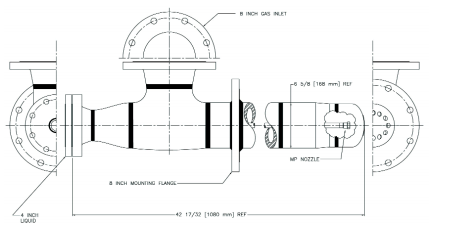

Product Description: Large Scale Bete SpiralAir-type Nozzle

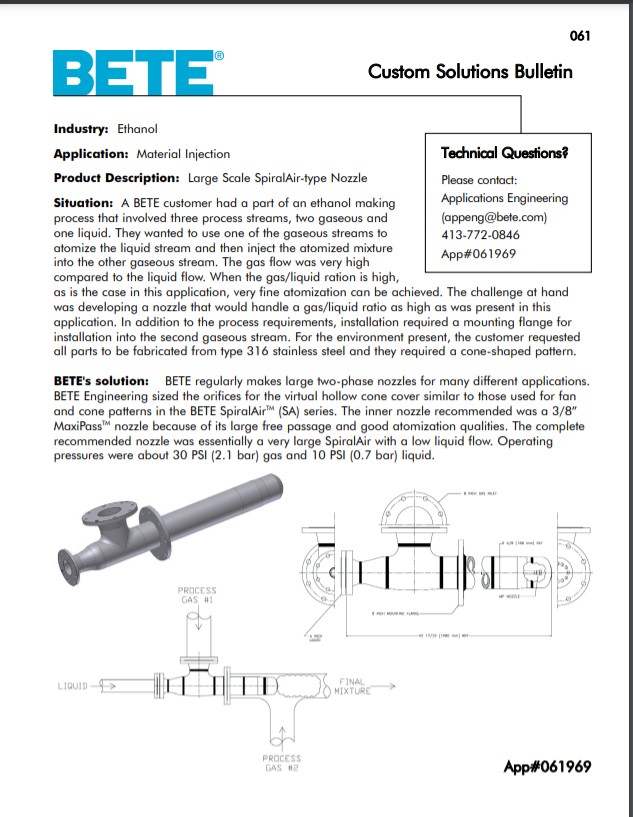

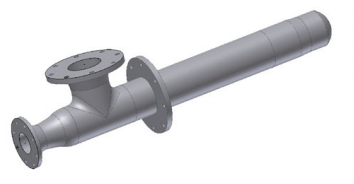

Situation: A Bete customer had a part of an ethanol making process that involved three process streams, two gaseous and one liquid. They wanted to use one of the gaseous streams to atomize the liquid stream and then inject the atomized mixture into the other gaseous stream. The gas flow was very high compared to the liquid flow. When the gas/liquid ratio is high, as is the case in this application, very fine atomization can be achieved. The challenge at hand was developing a nozzle that would handle a gas/liquid ratio as high as was present in this application. In addition to the process requirements, installation required a mounting flange for installation into the second gaseous stream. For the environment present, the customer requested all parts to be fabricated from type 316 stainless steel and they required a cone-shaped pattern.

Solution: Bete regularly makes large two-phase nozzles for many different applications. Bete Engineering sized the orifices for the virtual hollow cone cover similar to those used for fan and cone patterns in the Bete SpiralAir (SA) series. The inner nozzle recommended was a 3/8″ MaxiPass nozzle because of its large free passage and good atomization qualities. The complete recommended nozzle was essentially a very large SpiralAir with a low liquid flow. Operating pressures were about 30 PSI (2.1 bar) gas and 10 PSI (0.7 bar) liquid.

Custom Spray Nozzle Solutions – Ethanol Making Process Drawings and Sketches:

.jpg)