Custom Spray Nozzle Solutions – Chemical-Resistant Tank Washing Nozzle

Application #062006

Industry: Chemical Processing

Application: Tank Washing

Product Description: Chemical-resistant Bete Tank Washing Nozzle

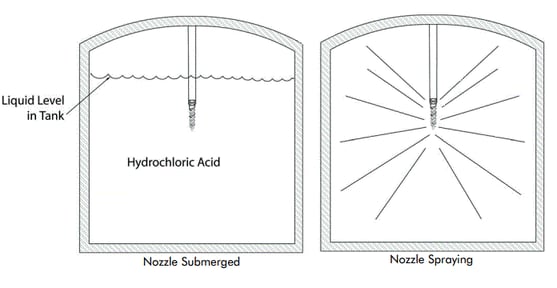

Situation: Bete Applications Engineers received an inquiry from a Bete customer who had an 8′ (2.5m) glass tank he needed cleaned. The tank normally held liquid with a high concentration of hydrochloric acid (HCl). The system was to be a Clean-in-place (CIP) system, which meant the nozzle would always be in the tank. The system was washed with 200° F (93° C) de-ionized water. The available opening into the tank was only 2″ (50mm) in diameter.

Solution: To be compatible with the hydrochloric acid, either a plastic or a nickel alloy (Hastelloy or Inconel) would have to be used. Since the wash water was 200° F (93° C), which is too high to comfortably use plastics, Hastelloy was selected. A TW1 was selected for its compact size that allowed it to fit through the 2″ (50mm) opening on the tank. Since BETE utilizes its own investment casting facility, a small run (two, in this case) of unique materials is not difficult at all. The nozzles were quoted, cast and sent within four weeks, the standard lead time for our production facility.

Custom Spray Nozzle Solutions – Chemical-Resistant Tank Washing Nozzle Drawings and Sketches:

.jpg)