Custom Spray Nozzle Solutions – Tantalum Nozzle Deluge Wash

Application #031377

Industry: Chemical Processing

Application: Deluge Wash

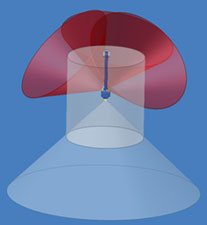

Product Description: Tantalum Bete CLUMP

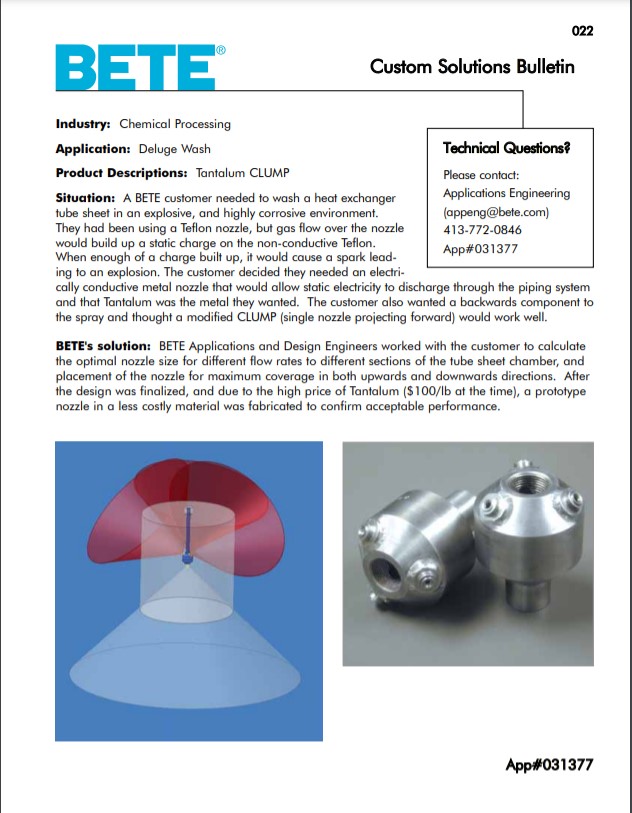

Situation: A Bete customer needed to wash a heat exchanger tube sheet in an explosive, and highly corrosive environment. They had been using a Teflon nozzle, but gas flow over the nozzle would build up a static charge on the non-conductive Teflon. When enough of a charge built up, it would cause a spark leading to an explosion. The customer decided they needed an electrically conductive metal nozzle that would allow static electricity to discharge through the piping system and that Tantalum was the metal they wanted. The customer also wanted a backwards component to the spray and thought a modified Bete CLUMP (single nozzle projecting forward) would work well.

Solution: Bete Applications and Design Engineers worked with the customer to calculate the optimal nozzle size for different flow rates to different sections of the tube sheet chamber, and placement of the nozzle for maximum coverage in both upwards and downwards directions. After the design was finalized, and due to the high price of Tantalum ($100/lb at the time), a prototype nozzle in a less costly material was fabricated to confirm acceptable performance.

Custom Spray Nozzle Solutions – Tantalum Nozzle Deluge Wash Drawings and Sketches:

.jpg)