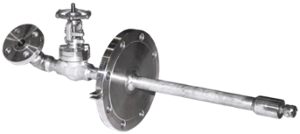

Internal Mix, Pressure-Fed Pneumatic Spray Nozzles

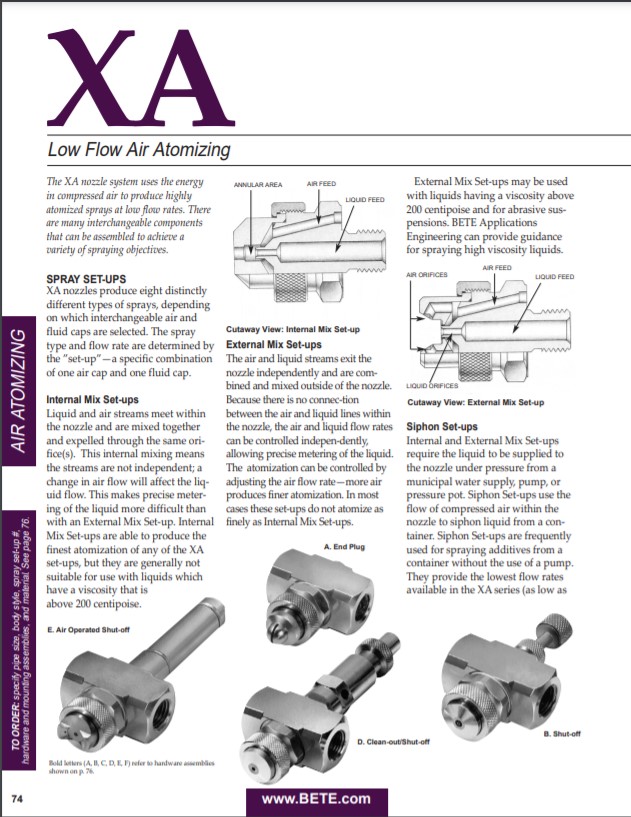

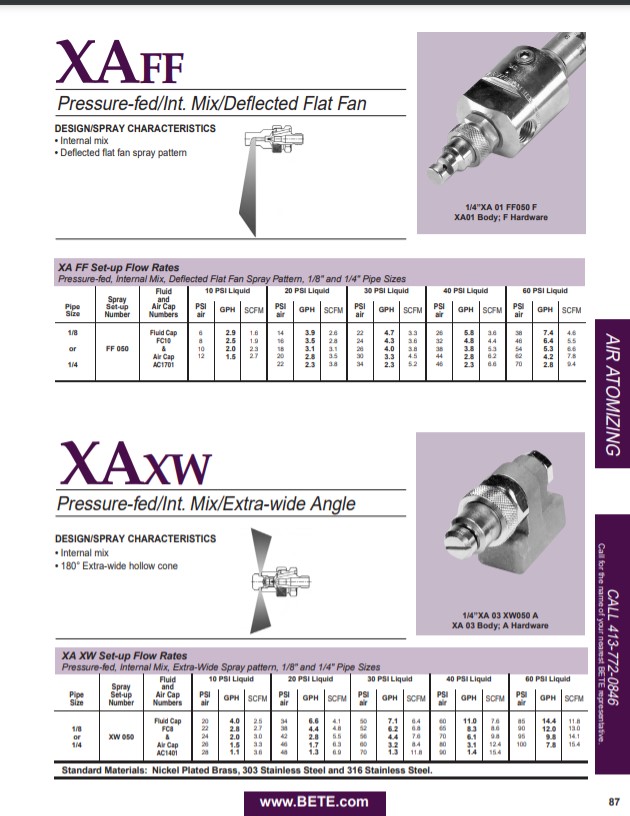

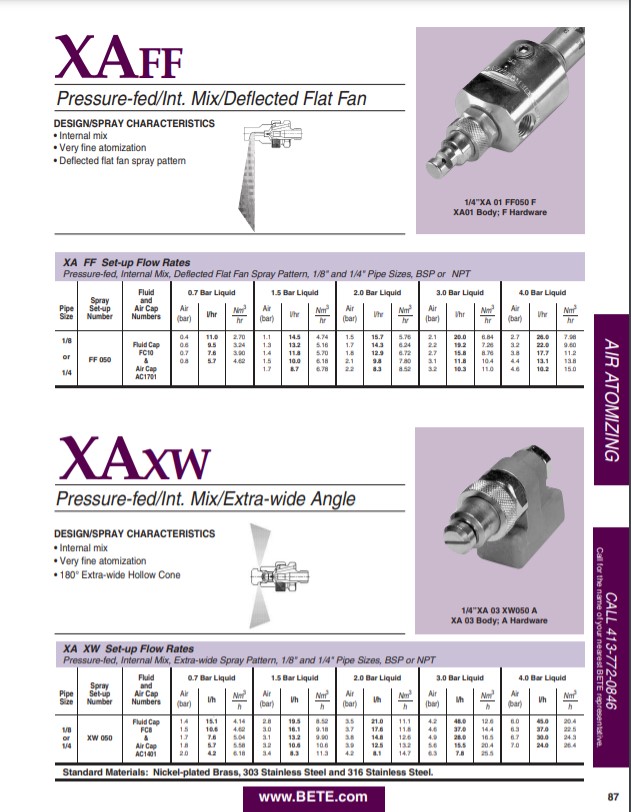

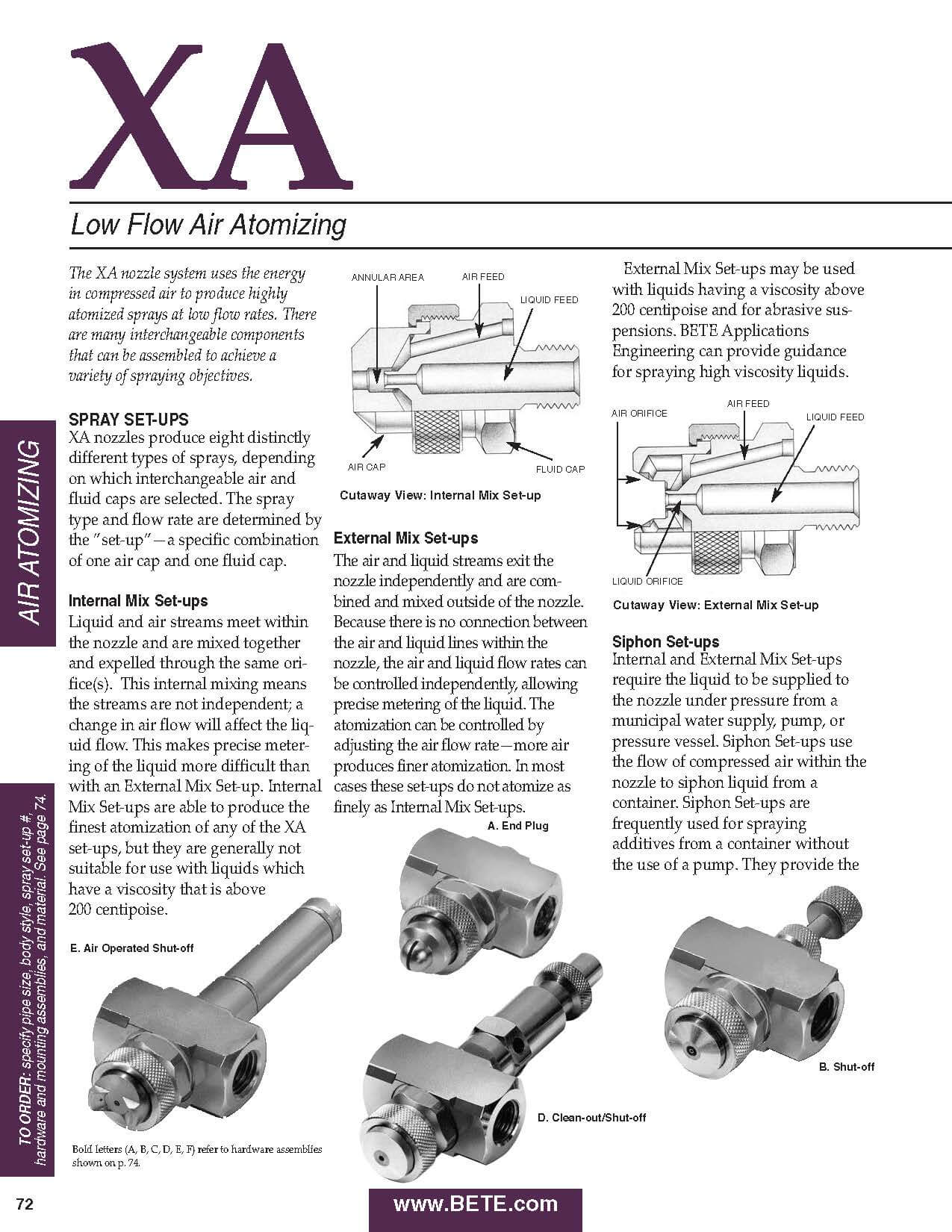

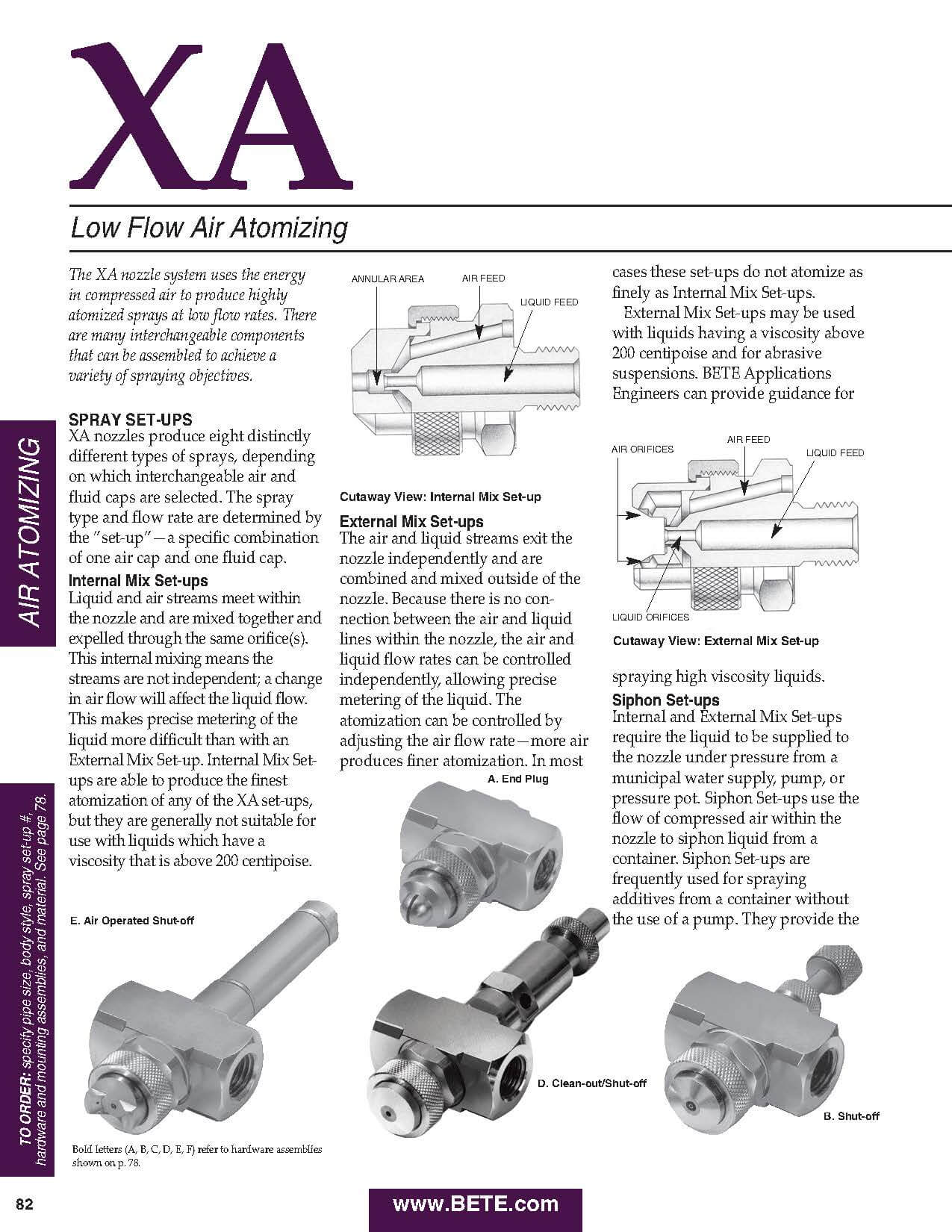

John Brooks Company carries a complete range of two-fluid (typically compressed air & water) atomizing BETE nozzles. The BETE XAFF spray nozzle is part of the BETE XA Spray Nozzle system. It uses the energy in compressed air to produce highly atomized sprays at low flow rates (1.0 to 280 liters per hour). XA nozzles produce eight distinctly different types of sprays, depending on which interchangeable air and fluid caps are selected. The spray type and flow rate are determined by the “set-up”- a specific combination of one air cap and one fluid cap.

Design Features of BETE XAFF Spray Nozzles:

- Internal Mix

- Deflected flat fan spray pattern

- Fine Atomization

Spray Patterns:

- Fan Spray Nozzles

- Air Atomizing Spray Nozzles

| Available Spray Angle | Materials | Available Connection Types |

| 145° | Nickel-plated Brass, 303, 316, Nickel-plated Brass / 304, 303 / 304 |

|

How Spray Pattern is achieved:

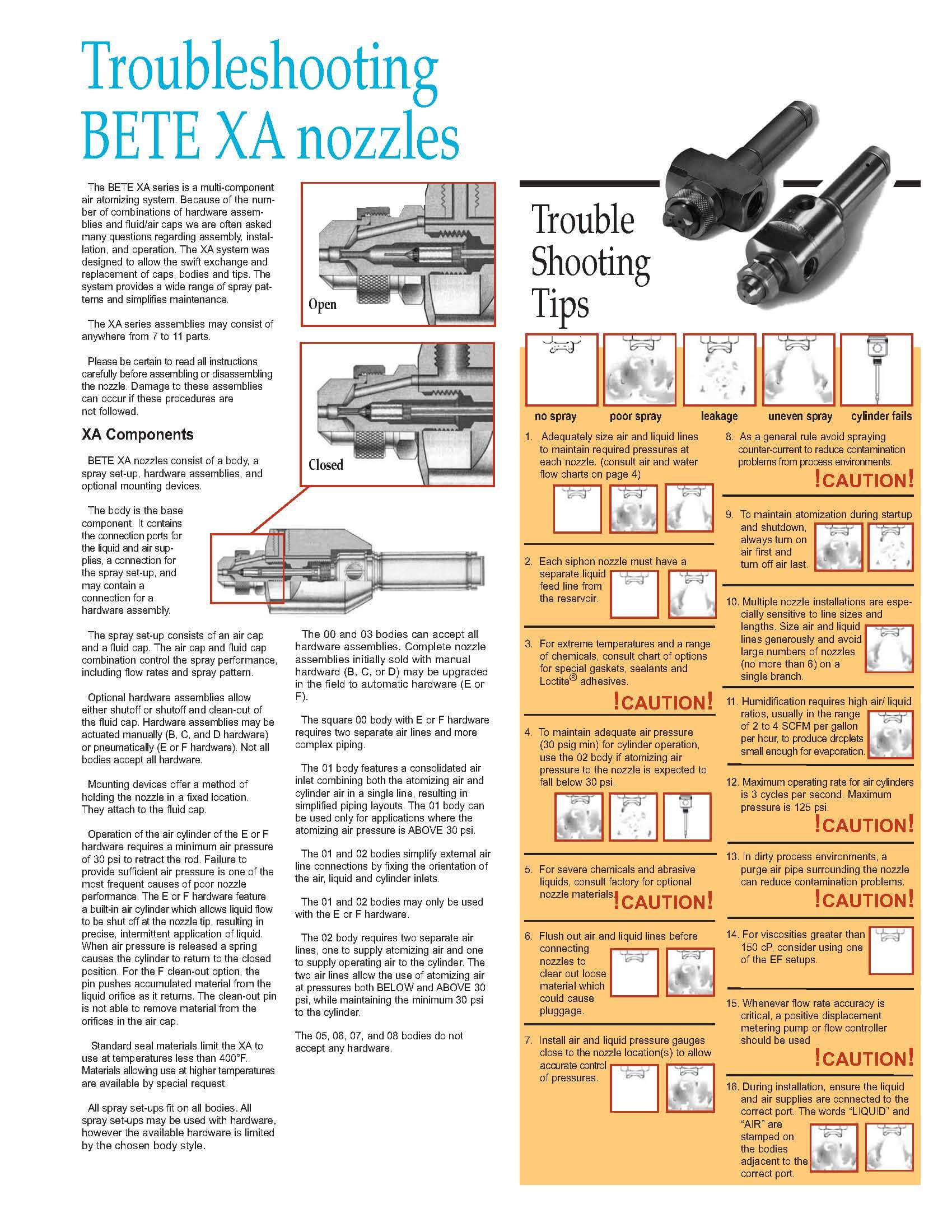

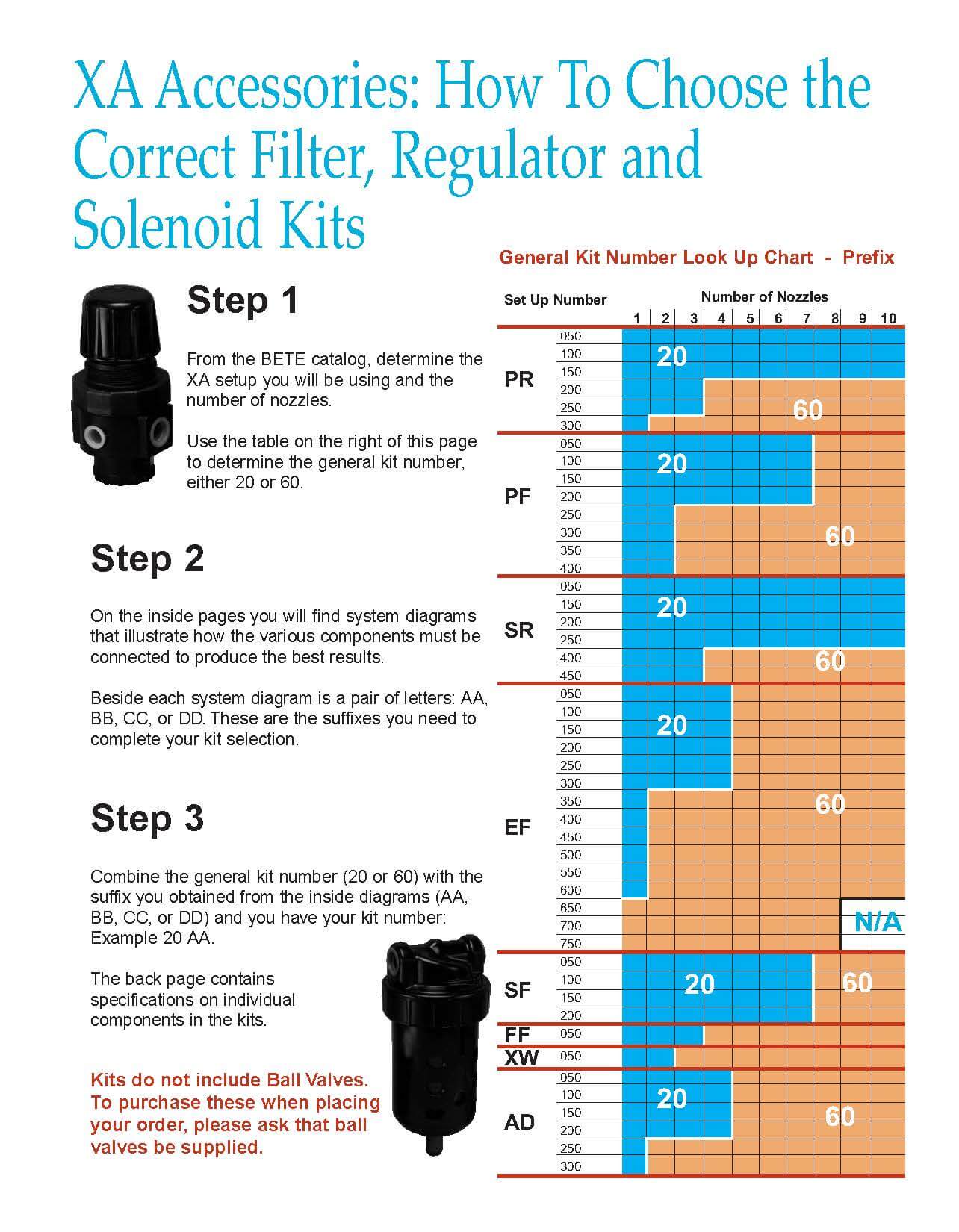

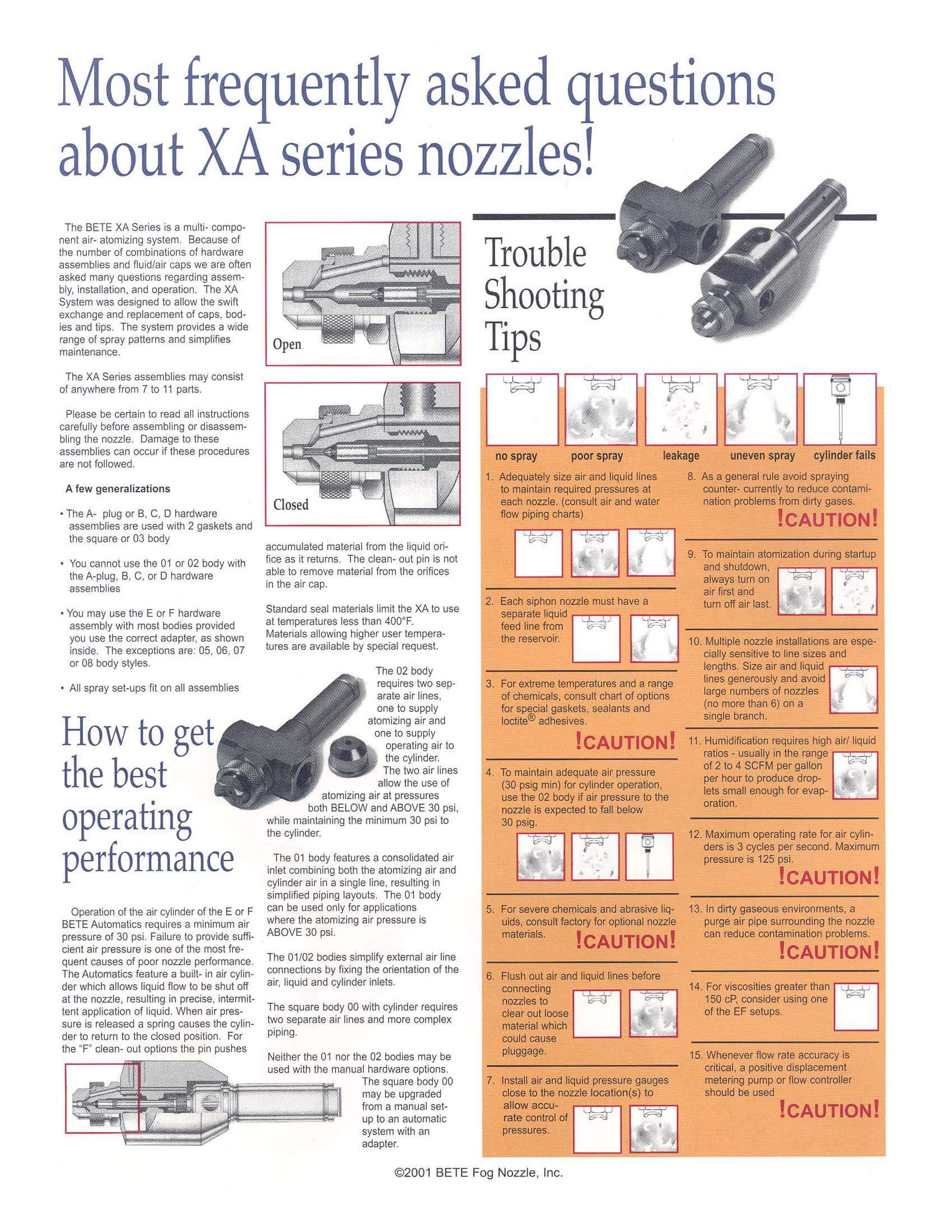

- In a pressure-fed system, the liquid is under pressure to either internal or external mix BETE XA Series nozzles. Air and liquid regulators control the fluid delivery pressure, while the air filter and liquid strainer ensure the supplied fluids are of high quality. Maintaining operational control is done by manual or solenoid valves used with various hardware assemblies.

- Liquid and air streams combine inside the nozzle, are mixed, and exit through the same opening, creating a deflected fan spray pattern.

- The streams are not independent; shifts in airflow will influence the liquid flow.

Spray Nozzle Diagram:

Applications for the BETE XAFF Spray Nozzles:

- Air Atomizing

- Air Conditioning

- Coating

- Concrete Curing

- Cooling: Evaporative

- Fogging

- Humidification

- Lubrication

- Misting

- Moistening

- Odor Control

- Scrubbing: Conditioning

- Scrubbing: Dry