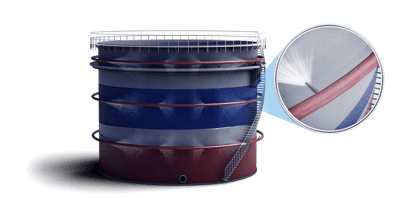

A Water Wall is a spray of water that acts as a barrier to shield personnel and equipment against radiant heat, harmful gases, and flames. The more water sprayed to form the suppression wall, the better the fire protection and shielding. High pressure and flow rates project water faster and further to form a larger buffer between the heat source and the protected areas.

Flat fan style nozzles are common and can produce an adequate barrier for some applications. However, full cone nozzles, particularly wide coverage spiral nozzles, are usually superior as they form a cone of liquid rather than a very thin plane of liquid. The spray pattern of BETE’s spiral full cone nozzles consists of multiple concentric cones. These provide layered security zones with a mix of coarser droplets, ideal for wind drift resistance and surface wetting encapsulating and projecting smaller droplets, ideal for cooling and absorbing heat.

Common Uses And Industries

- Protect personnel, evacuation routes & muster areas, equipment, and structures from radiant heat

- Heat protection from flare booms

- Escape pathways for personnel during fire

- Protection for firefighters and emergency responders

- Curtain off wellheads, storage tanks

- Protect machinery, tools, and the water supply pumps used for fire suppression systems

________________________________________________________________________________________________________________________

Important Factors to Consider When Selecting a Water Wall Nozzle:

Size & Shape of the target area, equipment, or enclosure

Applicable design specifications and requirements

Required flow rates/coverage densities

Available nozzle mounting locations

Available pressure drop (∆P) across the nozzle:

- ∆P = supply pressure at nozzle inlet – process pressure outside nozzle

As a nozzle manufacturer, BETE Fog Nozzle, Inc. cannot assume responsibility for the design of life/safety systems