FM and UL Approved Full Cone Nozzles for Offshore Fire Protection

BETE N high-efficiency spiral nozzles are designed specifically with critical fire and explosion suppression applications in mind. These nozzles feature superior performance unequalled by traditional whirl nozzles and feature

- Simplicity of design

- Designed specifically with critical fire and explosion suppression applications in mind

- One-piece/no internal parts

- Clog-resistant

- All N1-N3W nozzles provided with integral strainer

- N1-N3W strainer: 316 SS, 24 mesh (0.027" opening)

- Three standard pipe sizes—½”, 1″ and 1½”

- Male connection

- Factory Mutual, U.S. Coast Guard and Lloyd’s Register approved models

Spray Characteristics of the Bete N Fire Protection Nozzle:

- Two spray cones—an outer, wide angle cone and a narrower inner cone—combine to give full cone effect

- Spray pattern: Full Cone

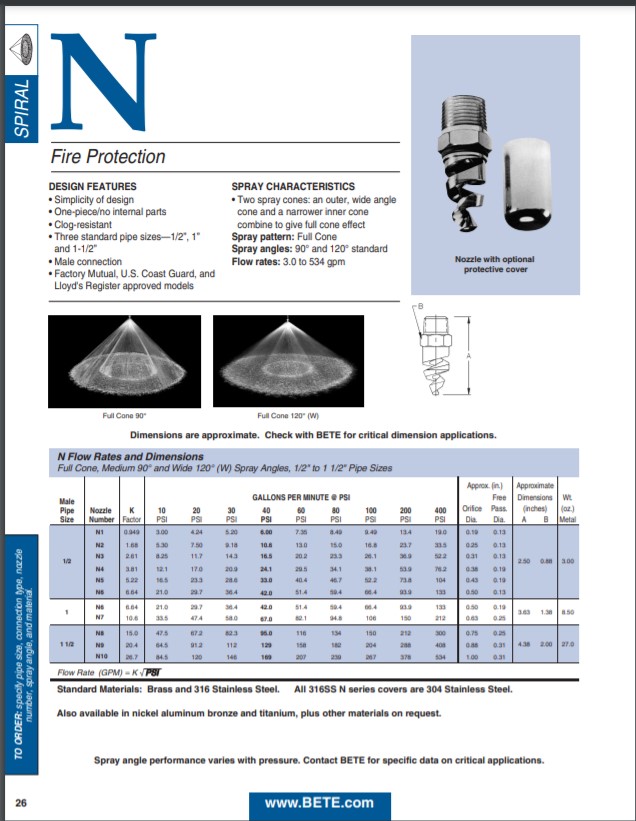

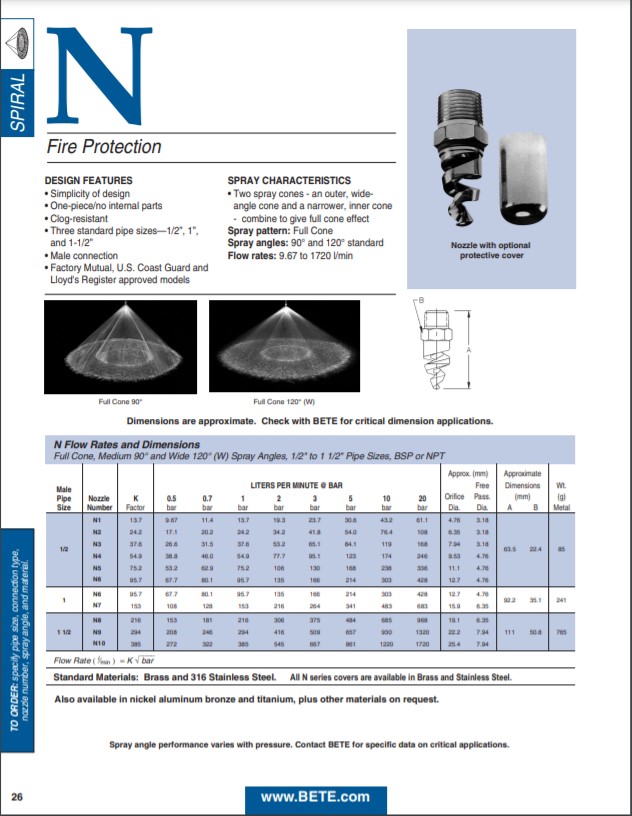

| Available Spray Angles | Flow Rate Range |

| 90 - 120° | 3 to 597 gpm |

| Available Connection Types | Materials |

|

Brass, 316, Nickel Aluminum Bronze, Titanium |

Bete N Superior Performance Characteristics:

- Sprays composed on droplets 30% to 50% smaller than conventional designs at equivalent pressures

- Extraordinarily large surface area of spray enhances evaporation and cooling

- Rugged, compact design

- Multiple concentric cone spray, unique to spiral pattern, maximizes contact

Bete N Superior Fire/Loss Prevention Applications:

- Gas wellhead protection

- Safeguarding ship-borne cargo

- Storage tank protection

- Secondary explosion protection in explosive, dusty environments

- Mitigation of HF and other toxic gas releases

Also available in nickel aluminum bronze and titanium, plus other materials on request.

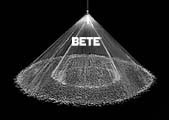

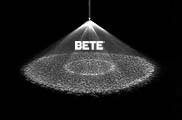

Spray Angle Visual: 90° and 120°

How Spray Pattern is Achieved

- The spray pattern of the spiral nozzle is formed by the fluid shearing along with the turns of the spiral, which produce multiple concentric cones. These cones form 2 to 3 bands of relatively coarse droplets, surrounded by wider bands of relatively fine droplets.

- The large surface area of spray improves evaporation and cooling.