Understanding Foam in Industrial Processes and the Need for Foam Control

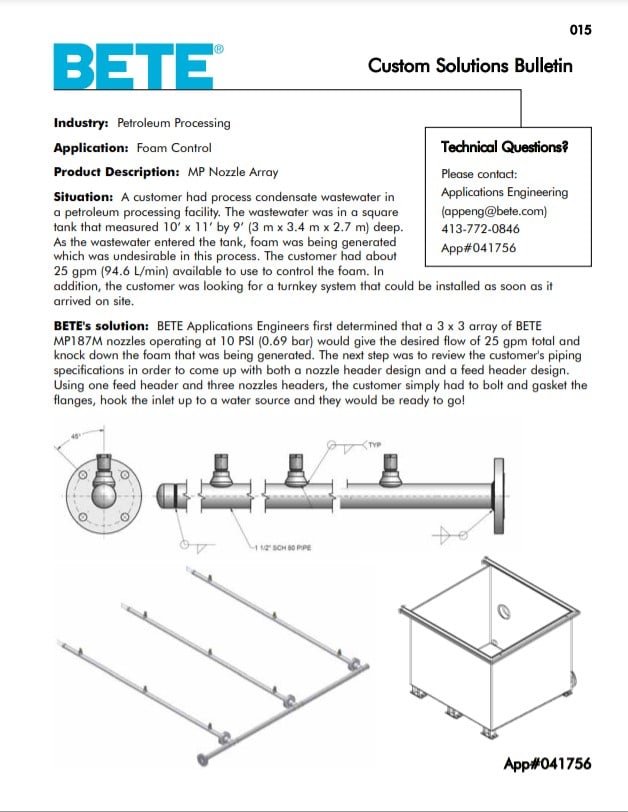

Foam, a dispersion of gas (usually air) in a liquid, can be problematic in various industrial processes and facilities. It can lead to overflow in vessels, hazardous working conditions, processing interference, material damage, and slow tank drainage. Efficiently managing foam involves spraying liquid onto the surface of the affected area, like a pool, vessel, or reservoir, to break the foam bubbles upon impact with droplets from the spray.

Common Uses & Industries Benefiting from BETE Spray Nozzles

In foam control applications, utilizing specialized nozzles is crucial. BETE spray nozzles play a pivotal role in this context, offering effective solutions for foam mitigation across a range of industries and applications, including:

In foam control applications, utilizing specialized nozzles is crucial. BETE spray nozzles play a pivotal role in this context, offering effective solutions for foam mitigation across a range of industries and applications, including:

- Aerobic and anaerobic digesters

- Food & Beverage Industry

- Launders

- Mitigation of foam in vegetable juices and high yeast content beverages

- Mixing vessels

- Seawater intakes

- Water and Wastewater Treatment Industry

- Weirs and spillways

Important Factors to Consider When Selecting BETE Foam Control Nozzles

When considering foam control nozzles, several important factors come into play:

- Required coverage: Strategically placing a line of BETE spray nozzles across a rotating tank vessel ensures comprehensive coverage, effectively mitigating foam.

- Static vs. moving fluids: Tailoring nozzle selection based on whether the fluid is static or in motion is crucial for optimal foam control.

- Available pressure drop (∆P): Adhering to specific pressure drop requirements ensures the production of appropriate droplet size and velocity for effective foam control.

- Available nozzle mounting locations: Considering the optimal mounting locations for BETE spray nozzles ensures efficient foam control in targeted areas.

- Foam thickness and rate of build-up: Properly gauging and adjusting droplet size to break up and mitigate foam effectively is essential for efficient foam control.

- Nozzle clog resistance: Selecting BETE spray nozzles with excellent clog resistance is crucial, especially in applications involving recirculated foam control fluid with solid particles.

-

Control high starch content in juice processing

Optimizing Foam Control: Leveraging BETE Spray Nozzles

For foam control applications, leveraging BETE Spray Nozzles is a smart choice, particularly when dealing with high starch content in juice processing and other challenging scenarios. Explore our range of BETE Spray Nozzles to optimize foam control in your specific industry and application.