A much smaller amount of scrubbing fluid is sprayed into the gas flow than in a corresponding wet scrubber system in dry scrubbing. A dry scrubbing system intends to limit the volume of fluid injected so that the liquid component evaporates completely, leaving either a gaseous or solid component that will react with the contaminant and allow it to be removed from the system.

These systems are frequently used to remove acid gases from combustion streams by injecting an alkaline slurry. For example, in coal power plants, a lime slurry will be sprayed into boiler exhaust to remove sulfur oxides (SOx). The flue gas is hot enough. The slurry is sprayed finely enough to fully evaporate while reacting with the flue gases to neutralize the acid and form solid particulates that can be more easily removed from the exhaust gas.

Common Uses and Industries

- Remove contaminants from gas streams

- Acid gas removal from process streams

- HCL removal

- Flue Gas Desulfurization Industry

- SO2 removal from combustion gases

- Chemical Processing Industry

- Petrochemical Processing Industry

- Pollution Control Industry

________________________________________________________________________________________________________________________

Important Factors to Consider When Selecting a Dry Scrubbing Nozzle:

- Scrubber duct size, velocity, pressure, temperature, and fluid composition

- Required coverage

- Nozzle mounting location and orientation

- They may be swept away of they are too small, especially in a fast-moving gas flue

- If they are too large, they may not fully evaporate, leaving a wet residue on the walls of the scrubber that can harden and build up over time

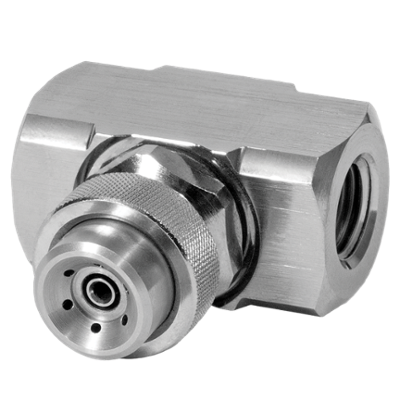

Required materials of constriction for corrosive environments

- Spray media density and viscosity

- Require scrubbing fluid flow rate

- ∆P = supply pressure at nozzle inlet – process pressure outside nozzle

- Availability of compressed air or other gases for atomization