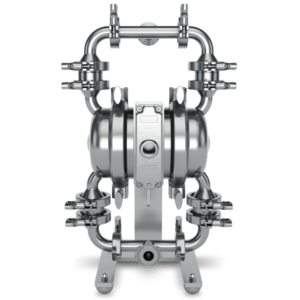

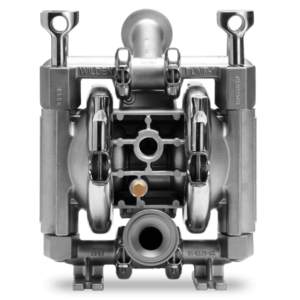

Wilden Pure-Fuse Integral Piston Diaphragms (IPDs) are the ideal solution for food, beverage and pharmaceutical applications. They offer clean-in-place (CIP) capability, and superior flow and suction life over competitive IPDs.

Pure-Fuse Diaphragms in Hygienic Applications

|

|

|

|

|

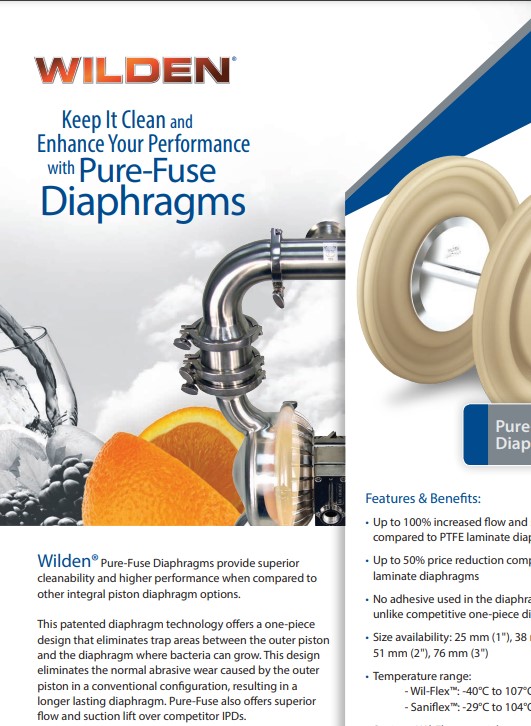

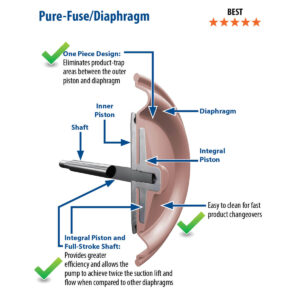

Features & Benefits of Pure-Fuse Diaphragms

Wilden Pure-Fuse Diaphragms (IPD) feature a one-piece design that offers a safe, clean and reliable product transfer with no product entrapment areas to minimize product contamination and risk liabilities. These diaphragms have a smooth, contoured shape and no outer piston. IPDs have greater durability and flex life, and are compatible with existing shafts and supporting hardware. They also provide greater flow rates and faster installation, all without sacrificing performance.

- Up to 100% increased flow and suction lift compared to PTFE laminate diaphragms

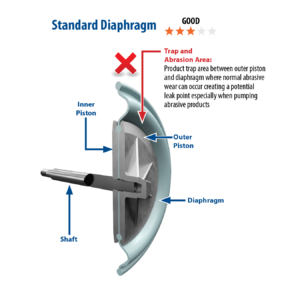

- Elimination of a potential leak point at the outer piston when pumping product

- Elimination of outer-piston abrasion for longer life, especially when pumping abrasive fluids

- No adhesive used in diaphragm construction unlike competitive one-piece diaphragms

- Easy cleanability for faster changeovers between product

- Up to 50% price reduction compared to PTFE laminate diaphragms

- Sanitary materials meet FDA CFR 21.177, 3A requirements, and 1935/2004/EC (1935/2004/EC – only available in Saniflex Material)

- Available Sizes: 25 mm (1”), 38 mm (1-1/2”), 51 mm (2”), 76 mm (3”)

Available Materials:

- Wil-Flex™ (Santoprene®)

- Abrasion and chemical resistant

- For acidic and caustic applications such as sodium hydroxide, sulfuric or hydrochloric acids

- Also available in food grade option that complies with FDA CFR 21.177

- Excellent flex life, abrasion resistance and durability

- Saniflex™ (Hytrel®)

- Outstanding sealing of low specific gravity and highly lubricious materials

- Excellent for food applications, fats and oils, and complies with FDA CFR 21.177 standards

- Good flex life, excellent abrasion resistance and durability