1-1/2” | 38 mm

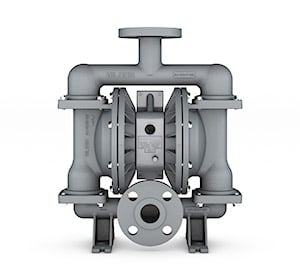

Wilden HS430S FIT Metal High Pressure Pump performance. A reliable performer, this pump has superior flow rates and can produce higher pressures (250 psig vs 200 psig) compared to competitor 1-1/2” (38 mm) pumps.

The FIT design uses a wetted path that minimizes the number of fasteners and allows for single socket reassembly for faster, easier maintenance compared to legacy Wilden pumps and competitor high pressure pumps.

Wilden HS430S FIT Metal High Pressure Pumps are designed for superior containment, are direct replacements for existing 1-1/2” (38 mm) high pressure pumps and do not require repiping of your application. The HS430S FIT high pressure metal pumps feature a “Simplex” design – meaning that one liquid chamber is used to pump fluid while the other is used as a pressure amplification chamber. With a 2:1 pressure ratio, this pump generates 17.2 bar (250 psig) and does not require costly external boosters or amplifiers to achieve this discharge pressure.

- Superior flow rates (+48% more than Yamada, +17% more than ARO)

- 430 designates ANSI or DIN flanged inlet/discharge liquid connections

- Available with Pro-Flo® SHIFT Air Distribution System (ADS)

- Wetted housing materials available: aluminum or stainless steel

- Max. liquid discharge pressure: 17.2 bar (250 psig)

Wilden HS430S FIT Metal Benefits and Features

The Successful Solution

- Higher flow rates/Increased pump output

- High pressure output

- Intrinsically safe

- Bolted connections for superior containment

- Variable flow and pressure

- Shear-sensitive

- Dry-run capable

- Portable and submersible

- Viscous and non-viscous product transfer

- Large solids passage

- High suction lift

- Ease of operation and maintenance

Higher ROI

- Exact fit from bolt-down footprint to inlet/discharge connections to reduce installation costs and eliminate repiping expenses

- Fewer fasteners compared to other pumps with easy accessibility using power tools for faster maintenance and less downtime

- Flexibility in aligning the wetted path assembly through lateral adjustment of the manifolds for easier installation into poorly piped systems

Dependable

- Longest Mean Time Between Repair (MTBR)

- Increased On/Off reliability

- Reduced turbulence

- Superior torque retention

- Anti-freezing ADS

- Reduced internal friction

Economical

- Greater flow per SCFM input

- Reduced air consumption and kilowatt usage

- Lower operational costs and downtime

- Optimized applications

Wilden HS430S FIT Metal Performance

WETTED HOUSINGS

(Water Chambers and Manifolds)

| Material | Ship Wt |

|---|---|

| Aluminum | 29 kg (64 lbs) |

| Stainless Steel | 55 kg (121 lbs) |

NON-WETTED HOUSINGS

| Description | Material |

|---|---|

| Center Section | Aluminum, Stainless Steel |

| Air Valve | Aluminum, Stainless Steel |

FLOW RATE

- TO 280 LPM (74 GPM)

MAX PRESSURE

- 8.6 BAR (125 PSI) – MAX DISCHARGE PRESSURE 17.2 BAR (250 PSIG)

MAXIMUM SUCTION LIFT CAPABILITY

- 2.0 m (6.8’) Dry, 9.0 m (29.5’) Wet

MAXIMUM DIAMETER SOLIDS

- 6.4 mm (1/4″)

DISPLACEMENT PER STROKE

- TPE-Fitted- 1.66 L (0.44 GAL)

Elastomer Options

| Material | Temperature Limits |

|---|---|

| Wil-Flex™ | -40 to +107 °C (-40 to +225 °F) |

Certifications

CE Mark (Conformité Européene – European Conformity)

![]()

Wilden® Pump & Engineering LLC has met the criteria for placing the CE mark on our product line. On December 3, 1999, Wilden fully self-certified its product line by meeting all the regulations of the Machinery and PED (Pressure Equipment) Directives. Every pump manufactured by Wilden will now receive the CE mark. Each pump box will also include a Safety Supplement manual in the eleven official languages of the European Community. This CE mark certification is indicative of Wilden’s pledge to providing our distributor network with all the sales tools necessary to excel in a global economy.

ATEX (ATmosphere EXplosible)

It is only natural that the worldwide leading producer of air-operated double-diaphragm pumps complies with the ATEX 100A directive for explosive atmospheres. The European community and their safety are of the utmost importance to us. We take responsibility for not only our product, but also for the supporting documentation and compliance of necessary directives. Wilden is proud to introduce our metallic X pumps that comply with ATEX 94/9/EC Group I, category M2 and Group II, category 2 zones G & D. Our plastic X pumps comply with ATEX 94/9/EC Group II, category 2, zone G.