Critical Equipment

Manufacturers who use chemical-based compounds such as caustics, acids, solvents and polymers know that valuable chemicals are pivotal to the production process but can also be extremely dangerous and harmful to site personnel, the environment and the productivity of the operation if not handled properly and correctly contained. This is why it's extremely critical to select equipment that can rise to the challenges inherent in the manufacture, transfer, transport and containment of chemical configurations.

The AODD Pump Solution

Improvements in operational efficiency coupled with the ability to handle most chemicals make the AODD diaphragm pump a perfect choice for chemical processors. AODD pumps not only outperform competitive technologies in terms of reliability and cost-effectiveness, but do so in a manner that prevents leaks and cross-contamination.

Features and Benefits

- Versatile

- Easy to maintain

- Leak-free design

- Seal-less

- Run-dry capable

- Great suction lift

- Portability

- Energy savings

Chemical Process Applications

- Acid transfer

- Polymer transfer

- Chemical dosing

- Low-solvent coating

- Solvent transfer

The Wilden Solution

|

|

|

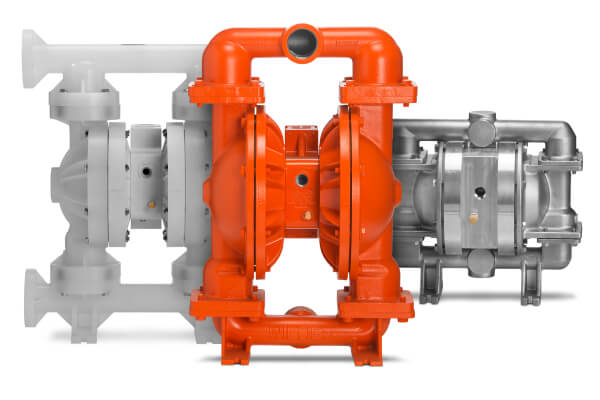

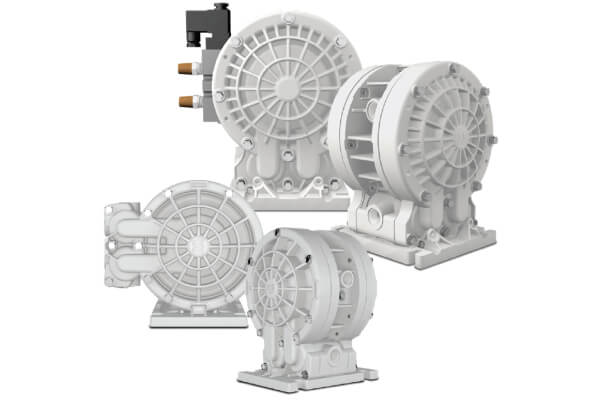

| Pro-Flo SHIFT Series - Bolted Metal and Plastic AODD Pumps | Chem-Fuse Integral Piston Diaphragms for AODD Pumps | Specialty Series – Velocity™ Compact AODD Pumps |

|

|

|

Resources

|

|

|

|

| SABA Success Story | Wilden AODD Pumps in Glue Applications | Wilden AODD Pumps in Sulfuric Acid Applications |

|

|

|

|

Wilden® Pro-Flo® SHIFT AODD Pump Outperforms Competitor In Head-To-Head Test |

Wilden Pumps in Dangerous Chemical Applications |

EMCO Optimizes its Operations at New Facility with Help of Wilden AODD Pumps