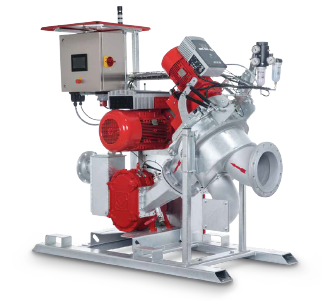

The Universal Standard Pump System

This Vogelsang BioCut VX186-130Q/RCQ-43Gpro is the efficient solution for treating and pumping large volume flows of viscous suspensions and media. And, at the same time, it reliably separates out heavy material and cuts disruptive or solid matter.

A Universal and Diverse Pumping System for Biogas Production and Biogas Applications

The Vogelsang BioCut was developed specifically to handle complex pumping challenges. This unit is highly compact due to its unique construction that combines a Vogelsang rotary lobe pump and the Vogelsang wet grinder, RotaCut. Acting as a central pumping system, the Vogelsang BioCut ensures rich media such as stones and metal parts are reliably removed from organic suspensions, liquid manure, and other fluids. During the process, the Vogelsang BioCut breaks down any troublesome matter in the fluids, such as biomass, and homogenizes the liquid, which makes pumping easier. This comprehensive treatment decreases the viscosity and minimizes the chances of floating layers occurring. This treatment results in a lower amount of energy used and a positive effect on gas yield.

Benefits of the Vogelsang BioCut

- Optimally coordinated components lead to cost-effective pumping

- Treats hard to breakdown matter and separates heavy materials before pumping

- Company design with minimal space requirements

- Reliable conveying of a wide range of challenging media

- Service and maintenance can be performed quickly and easily on site

Design and Operation of the Vogelsang BioCut

The Vogelsang BioCut is a cost-efficient and reliable pump that handles challenging heterogeneous media containing disruptive matter and heavy materials. It comprises a Vogelsang self-riming rotary lobe pump and a wet RotaCut grinder. The Vogelsang Rotary Lobe Pump draws media in and separates challenging foreign matters based on weight and size with the Vogelsang RotaCut. Larger debris is removed through the cleaning port during maintenance work. Solid, lighter media such as fibres and wood can be separated and broken down in the cutting screen, where they are broken down and mixed into the liquid. This results in a homogeneous pumpable suspension.

Service and Maintenance of the Volgesang BioCut Pump System

If necessary, you can also replace the axial wear plates, the pump housing segments and the Quality Cartridge mechanical seal.

The two components can both be maintained quickly on site, allowing the Vogelsang BioCut pump system to be put back into operation after a very short time. There is no need to dismount the pipe, reducing downtime to a minimum.

Features of the Vogelsang BioCut

- Heavy material separation

- QuickSerivce

- Break-proof shafts

- Element-based design

- Cutting screen geometry

- Quality Cartridge

- Compact Design

- Self-priming

Options of the Vogelsang BioCut

Connector BoxThe Connector box is an ideal addition. It improves the suction capacity of the rotary lobe pumps in the VX series and ensures large volumes of air or gas are reliably evacuated or pumped.

InjectionSystemThe InjectionSystem improves suction capabilities and increases efficiency through optimized volumetric efficiency. This addition increases the pump's service life and significantly enhances the foreign matter resistance of the pump.

Radial Wear PlatesThe construction of Radial Wear Plates with wear-resistant steel extends the maintenance intervals, simplifies maintenance and reduces costs.

HiFlo lobesVogelsang's HiFlo lobes ensure pulsation-free pumping and, as a result, an increased lifetime for the drive and coupling. The suction volume is increased due to the higher number of sealing lines, and the enhanced internal sealing allows for suction from deep pits.

Cutting ScreensVogelsang offers cutting screens for the RotaCut with a free passage of 4 mm to up to 50 mm, depending on the unit size. Stainless steel designs are available for aggressive media.

ACC PlusReduces the cost of maintenance and monitoring of the cutting by displaying the blade status on an external display. With the ACC Plus, you no longer require the cutter to be out of service and opened to determine the cutting blade status.

Auto-Reverse functionThe Auto-Reverse function detects blockages caused by heavy matter and takes corrective actions. Reversing the process further ensures that sharp cutting edges are always used while dull ones are sharpened on the opposite side.

Vogelsang, a supplier with over 80 years in the biogas sector, has worked continuously with customers to create innovative biogas fluid handling technologies. They offer a comprehensive portfolio of biogas machinery from start to finish in the fermentation process. Vogelsang has serviced thousands of installations and customers worldwide.