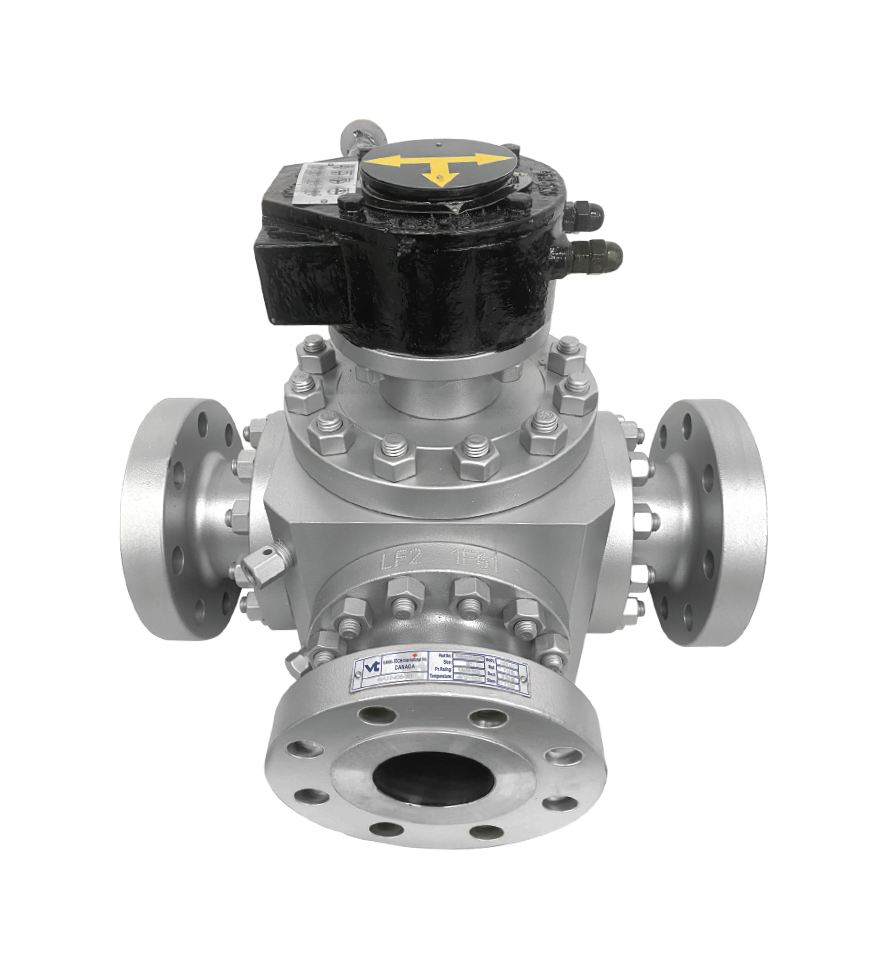

Three-way ball valves are used to switch over, mix and divide the flow of corrosive or non-corrosive liquid, steam or gas media. VAHN-TECH three-way ball valves are durable, versatile and cost-effective use in Chemical, Oil & Gas, Desalination or LNG application. Upon opening and closing, the smooth flow channel reduces the pressure loss. There are five choices of flow direction (1 for L-shaped and 4 for T-shaped) to meet each specific applications. VAHN-TECH three-way valves are easy to maintain, reducing the overall cost of operation. VAHN-TECH offers 2 design for 3-way valves: Floating ball design with cast body and Trunnion ball design with forged body. Forged body design is ideal for higher pressure operation, abrasive and corrosive media.

Features

- Valve seat can be designed into four-side seated floating ball and fixed ball, with smooth fluid state and reliable seal;

- Anti-blow out stem design;

- Anti-static design;

- Two position locking mechanism.

Specifications

| Design Standard | API 6D / API 608 / BS 5351 |

| Size Range | 2” – 24” |

| Pressure Rating | Cast Body (Floating Ball): Class 150 - 300 Forged Body (Trunnion Ball): Class 150 - 2500 |

| Working Temperature | -46˚C to 220˚C -50˚F ~ +428˚F |

| End Connection | ANSI B16.5 ASME B16.47 |

| Face-to-Face | ANSI B16.34 ASME B16.10 |

| Test & Inspection | API 598 / API 6D |