Seepex Progressive Cavity Pump Ensures Cost-Effective and Safe Ingredient Pumping for Sausage Manufacturing

How We Simplified the Operation, Ensured Better Production Control, and Lowered Wastage for Our Customer

The Challenge:

A meat processor in Eastern Canada needed help with the technology they were using to dispense gel covering their sausage meat. The process caused wasted ingredients and damage to the product, resulting in an inefficient process with high capital expenditures and wasted products. They were looking for a solution to simplify their process, increase production, and save money.

The Solution:

Our pump application experts collaboraed with the Customer to develop a solution. After considering that the gel had a viscosity of 3,000,000 cPs which put the pump at risk of damage by running dry and precise dosing of the gel was needed to ensure a high-quality product since the sheer sensitivity of the liquid influences feed rate, our Experts recommended a progressive cavity pump system. Since this technology is new to the application, a pump trial agreement outlining clear objectives and measurements of success for pump capacity, operational flexibility and accurate gel measurement was offered.

After a three-month trial, the Customer purchased the system. It has been effectively running without issue, saving the customer hundreds of thousands of dollars in capital expenditures and unnecessary product waste.

Pump Specs and Benefits

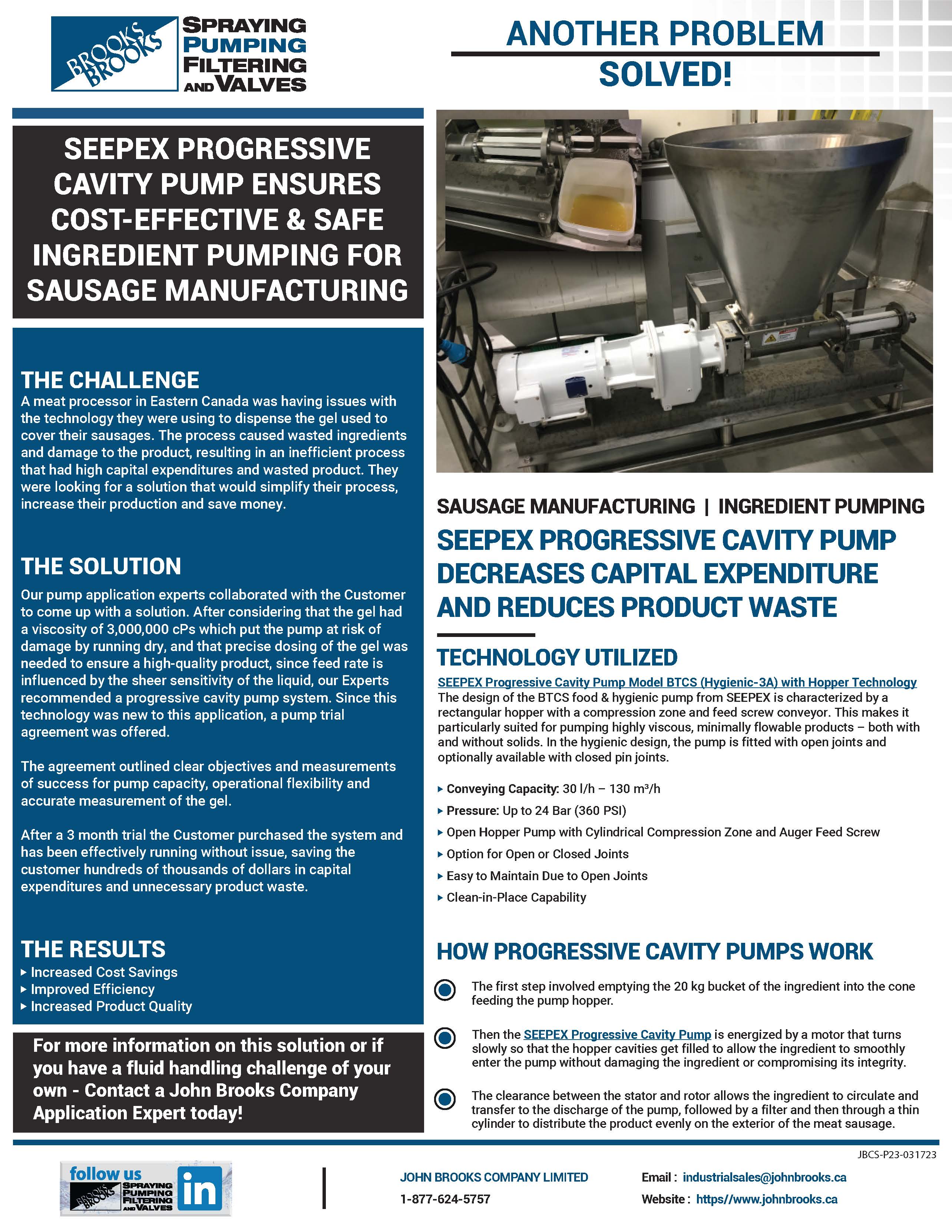

The BTCS food and hygienic pump design from SEEPEX is characterized by a rectangular hopper with a compression zone and feed screw conveyor. This hopper makes the SEEPEX particularly suitable for pumping highly viscous, minimally flowable products with and without solids. In the hygienic design, the pump is fitted with open joints. However, it is optionally available with closed pin joints.

Features and Benefits:

- Available with a choice of open hygienic joints or closed pin joints, suitable to your application

- Certified under the 3-A Sanitary Standards (variant with open joints) and designed in compliance with the EHEDG guidelines, and fitted with FDA-approved and EU 1935-2004 compliant components

- Conveying capacity: 0.03 – 130 m³/h (0.132 USGPM – 572 USGPM)

- Pressure: ≤ 24 bar (350 PSI)

- Unique housing geometry and open, hygienic pin joints facilitate optimal cleaning and sterilization: CIP, SIP, COP

- Optimal filling of conveying chambers through feed screw and conically closing compression zone

- Hermetically sealed elastomer sleeves are particularly suited for abrasive pumping media

- Minimal pulsation and low shear characteristics allow the gentle conveyance of sensitive media

How the Technology Works

- The first step involves emptying the 20 kg bucket of the ingredient into the cone feeding the pump hopper.

- Then the pump is energized by a motor that turns slowly so that the hopper cavities get filled to allow the ingredient to smoothly enter the pump without damaging the component or compromising its integrity.

- The clearance between the stator and rotor enables the feature to circulate and transfer to the pump's discharge, followed by a filter and then through a thin cylinder to distribute the product evenly on the exterior of the meat sausage.