Pulsafeeder PULSAtron Product Line

Pulsafeeder PULSAtron product line has evolved into a philosophy of design that continues to set the standards for the entire industry. Pulsafeeder engineers have developed a guided check valve system with a proven ‘seat and ball’ design that ensures reliable and accurate metering year after year.

PULSAtron Industrial Construction

Pulsafeeder’s fin cooled Solenoid enclosure dissipates heat ensuring that the pressure handling capability of the pump can be maintained. The thermally protected solenoid protects the pump from seizing up in extreme heat conditions with an automatic reset feature allowing the pump to resume operation up on cool-down. All PULSAtrons are tested and rated under hot conditions guaranteeing that the flow and pressure ratings meet the specifications. There are no standards when it comes to the type of chemicals our pumps may encounter. Therefore there is a variety of wet-end materials that the customer can choose from. Every pump is ‘configured to order’ with the customer designated wet-end materials that match the chemical requirements of the target application.

Application Expertise

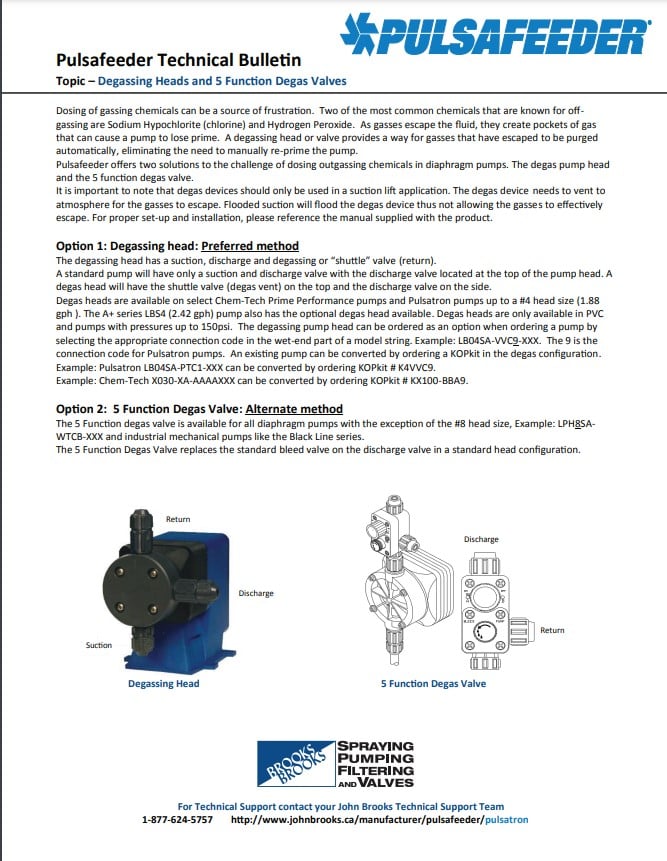

With more than 10 years of product evolution, the PULSAtron family continues to set the standard with the Degas Five Function Valve. PULSAtron can handle a variety of gaseous solutions. The PULSAtron family consists of nine unique series with 80 flow and pressure envelops to select from. Most models include our standard bleed valve assembly, foot strainer, injection valve and tubing. No matter what your application is, choose the PULSAtron that is right for you. Over 25 years of excellence, PULSAtron pumps carry agency approvals of ETL, ETL Sanitation, CE and NSF 61 (PVDF material and Degassing Head models).

Download the Technical Bulletin – Degassing Heads and 5 Function Degas Valves

|

|

|

|

|

| Series A Plus | Series C | Series C Plus | Series E |

|

|

|

|

| Series E Plus | Series E-DC | Series HV | Series MP |

|

| Series T7 |

Pulsafeeder, has been a leading manufacturer of metering pumps for over 80 years and offers a breadth of products used for the chemical injection or metering processes in the mining industry for the extraction of metals, minerals, stones, and fuels.

Have a Fluid Handling Problem? We can help you find a Pumping Solution.

John Brooks Company caters to diverse industries, offering suitable pump solutions for nearly all fluid handling needs - including yours! Our success hinges on fostering a collaborative partnership with you, where we help you find a tailored solution to enhance your systems, boost productivity, and minimize operational expenses

Consult with a John Brooks Company Pump expert today to help you determine the most suitable pump type for your application needs.