GAS PURIFIERS

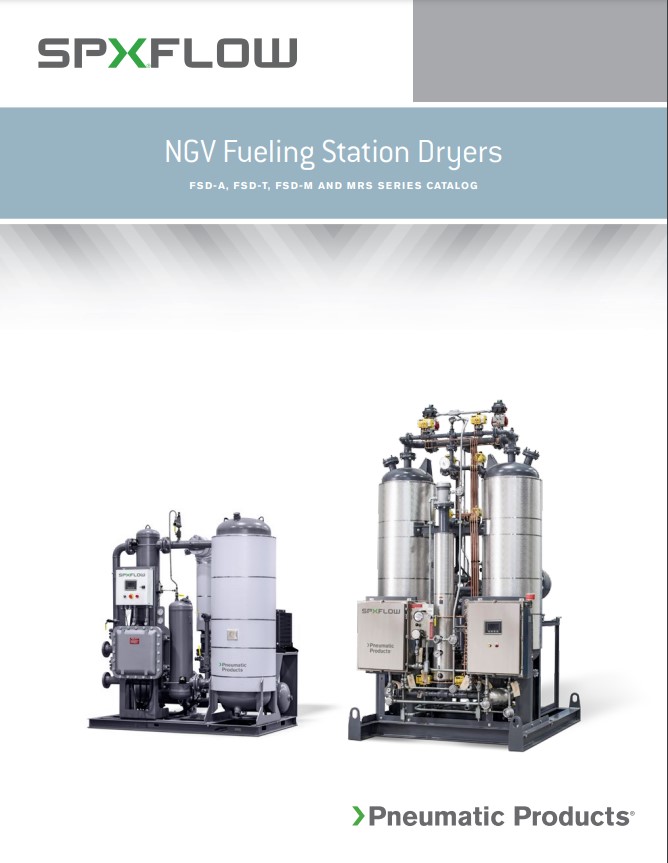

FSD-T Series twin tower purification systems are completely self-contained, fully automatic, heat-reactivated, closed-loop blower purge desiccant dryers designed to remove water vapor from natural gas.

Using molecular sieve as the drying media, these systems will continuously dry CNG down to an outlet moisture content of 0.5 lbs/MMscf, or lower.Specifically engineered for large flow heavy-duty NGV fleet refueling applications, FSD-T Series Twin Tower systems provide dry CNG 24 hours a day.

- Certified Quality Assurance – ASME Section VIII designed pressure vessels and piping designed per ASME B31.3

- Three-valve block and bypass piping for dryer isolation

- Ease of Service & Superior Corrosion Resistance – Removable stainless steel diffusers

- Downflow Drying – eliminates fluidization to extend desiccant life

- No Gas Lost to Purge – closed loop convection regeneration

- Energy Savings & Complete Diagnostics – microprocessor based

- Safe, Reliable & Dependable Operation –

– Electrical Enclosures for Class 1, Division 2, Group C and D classifications (Optional Class 1, Division 1)

– Heater Element and Over-Temperature Shutdowns

– Blower and Heater Interlocks - Air-cooled heat exchanger with TEFC fan motor, non-sparking fan blades, fan cycling control

- Complete Purification System – Factory mounted and piped coalescing 0.0014 ppmw oil & aerosol removal prefilter and 0.9m absolute particulate removal afterfilter

- Moisture separator and condensate collection vessel

- Heavy-Duty blower ensures reliable operation

- Incoloy sheathed, low watt density heater and insulated heater housing, dual set point temperature controller for monitoring and over-temperature protection