Hydro-Thermal Hydroheaters & Jet Cookers – Direct Steam Injection

Hydro-Thermal Hydroheaters (also known as a Jetcookers) are individual units or full custom systems, designed to your specifications. Each heater can be built directly onto a skid, ready to be inserted immediately into your production line.

INDUSTRIAL – Hydro-Thermal Hydroheaters |

|

|

Hydroheater®(Also known as the JetCooker™) Heats a wide range of liquids from water to heavy viscous slurries. - Read More Volume Capability: 1 up to 6,700 gpm [.2 up to 1,522 m³/hr] Uses: Pulp and Paper; Biofuels; Ethanol and Starch Conversion; Large Volume Water; Anaerobic Digestion; Cooking & more. Model Numbers: K410 | K411 | K412 | K413 | K414 | K415 | K416 | K417 | K510 | K511 | K512 | K513 | K514 | K515 | K516 | K517 | K610 | K612 | K613 | K614 | K615 | K616 | K617 | M101 | M103 | M104 | M105 | M106 | M107 | M108 | M109 | M110 |

|

Solaris®Optimized straight-through heater, handles heavy slurries, medium consistency pulp stock or higher solids content. - Read More Volume Capability: 5 up to 25,000 gpm [1 up to 5,678 m³/hr] Uses: Medium Consistency Pulp Stock, Bleaching, Anaerobic Digestion, and other Fibrous Slurries Model Numbers: S101 | S202 | S203 | S204 | S206 | S208 | S210 | S212 | S216 |

|

NOH – Non-Obstructing HeaterRugged, able to handle abrasive materials (such as sand or grit) or large particulate/fibrous materials. - Read More Volume Capability: 30 up to 3,035 gpm [6.8 up to 689 m³/hr] Uses: Pulp Bleaching, Cellulosic Ethanol, Meat Slurry, Diced Vegetables and Blanching, Mining and Metals, Municipal and Industrial Wastewater, and Inline Water Heating with a Large Temperature Rise Model Numbers: NOH2 | NOH4 |

|

ATTEC® SystemATTEC or Advanced Fluid Heating Skids are completely customized solutions that are designed, built and installed to individual specs. Hydro-Thermal will provide necessary components including piping and control systems. These skids can be used for processing any type of slurry including starch cooking, food manufacturing, chemical processing and everything in between. - Read More |

SANITARY |

|

|

Sanitary Hydroheater®The Sanitary Hydroheater is a perfect fit for applications in the food & beverage and pharmaceutical industries. The Sanitary heater is 3A Certified making it the heater of choice for processes that require fast and precise temperature control without any degradation in quality. - Read More Volume Capability: 1 up to 180 gpm [.2 up to 41 m³/hr] Uses: Food and Beverage Cooking, Cheese and Dairy Production, Sauces, and Pharmaceutical Fluids Model Numbers: A304 – A204 – A104 | A206 – A106 | A307 – A207 | A208 – A108 | A209 – A109 | A210 – A110 |

|

SilverLine™ Smart Cooking SystemSanitary 3A, CE certified and FDA compliant, stainless steel system for starches, slurries and high solid products. - Read More Volume Capability: 5 up to 200 gpm [1.1 up to 45 m³/hr] Uses: Soups, Sauces, Beverages, Dairy-based Products, Tomato-based Products, Starch-based Products, High or Low Shear Products, Pasteurization, Batch or Continuous Processing. |

|

Infuze Sanitary Cooking SkidCompact and fully sanitary cooking skid that helps products achieve finished recipe results, pasteurization or blended emulsification through 3-A, EHEDG and FDA certifications. - Read More Minimum Volume Capability: 3 up to 22 gpm [0.7 up to 5.0 m3/hr] Maximum Volume Capability: 30 up to 255 gpm [6.8 up to 57.9 m3/hr] Uses: Soups, Sauces, Slurries, Beverages, Dairy-based Products, Tomato-based Products, Starch-based Products, High or Low Shear Products, Blended Emulsification, Pasteurization, Batch or Continuous Processing. |

WATER ONLY |

|

|

EZ Heater®Water only applications - Read More Volume Capability: 2 up to 1,350 gpm [.5 up to 306 m³/hr] Uses: Tank Heating/Filling, Washdown, Clean-in-Place (CIP), Sanitation, Clean-Up Can Topping, Cook Pots, Chemical Reactors. Model Numbers: H310 | H320 | H330 | H340 | H360 | H2010 | H2015 | H2020 | H2030 | H2040 |

|

EZ Skid™ SystemFor Hot Water only, utilizes the EZ Heater. - Read More Volume Capability: 2 up to 1,350 gpm [.5 up to 306 m³/hr] Uses: Tank Heating/Filling, Washdown, Clean-in-Place (CIP), Sanitation, Clean-Up Can Topping, Cook Pots, Chemical Reactors Model Numbers: H310 | H320 | H330 | H340 | H360 | H2010 | H2015 | H2020 | H2030 | H2040 |

FLOW TECHNOLOGY |

|

|

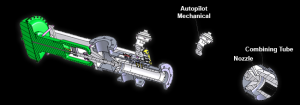

Autopilot | Autopilot Lite | CopilotAutomatic product flow technology that adjusts a Hydroheater to maintain constant pressure drop across the unit. - Read More Uses: Any K610 – K617 Hydroheater installations (also compatible on older K510 – K515 models) Local control panel with inputs for differential pressure transmitter signal, pressure drop set point and system enable (Auto/Manual). |