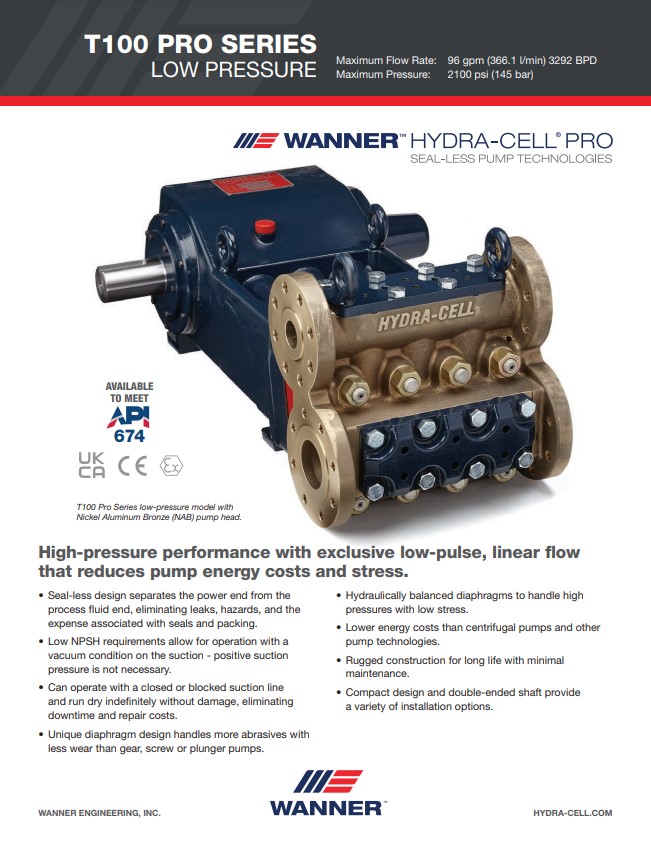

Hydra-Cell T100 Series pumps feature the Hydra-Cell seal-less design, eliminating clean-up costs from leaking seals or packing and protecting operators from dangerous fluids such as those containing hydrogen sulfide.

Hydra-Cell T100 Series Low Pressure Diaphragm Pump Features

Hydra-Cell Low Pressure Models T100E, T100F & T100H

- Seal-less design eliminates leaks, hazards and the expense associated with seals and packing

- Low NPSH requirements allow for operation with a vacuum condition on the suction - positive suction pressure is not necessary

- Can operate with a closed or blocked suction line and run dry indefinitely without damage, eliminating downtime and repair costs

- Unique diaphragm design handles more abrasives with less wear than gear, screw or plunger pumps

- Hydraulically balanced diaphragms to handle high pressures with low stress

- Lower energy costs than centrifugal pumps

- Rugged construction for long life with minimal maintenance

- Compact design and double-ended shaft provide a variety of installation options

| Maximum Flow Rate: | 96 gpm (366.1 l/min) 3292 BPD |

| Maximum Pressure: | 2100 psi (145 bar) |

Hydra-Cell T100 Series Low Pressure Pump Specifications

Hydra-Cell T100 Series Low Pressure

________________________________________________________________________________________________________________________

| Model | Flow Capacities @ Pressure psi (bar) | rpm | gpm | l/min | BPD |

|---|---|---|---|---|---|

| T100E | 1500 (103) | 450 | 96.0 | 366.1 | 3292 |

| T100F | 1850 (128) | 450 | 76.5 | 289.6 | 2623 |

| T100H | 2100 (145) | 450 | 68.0 | 257.8 | 2332 |

| Delivery @ Pressure psi (bar) | gal/rev | liters/rev | |

|---|---|---|---|

| T100E | 500 (34) | 0.220 | 0.831 |

| 1000 (69) | 0.217 | 0.821 | |

| 1500 (103) | 0.214 | 0.809 | |

| T100F | 500 (34) | 0.177 | 0.669 |

| 1000 (69) | 0.173 | 0.655 | |

| 1850 (128) | 0.170 | 0.644 | |

| T100H | 500 (34) | 0.159 | 0.601 |

| 1000 (69) | 0.155 | 0.587 | |

| 2100 (145) | 0.152 | 0.575 |

| rpm | gal/rev |

|---|---|

| Maximum: | 450 |

| Maximum API 674: | 375 |

| Minimum: | 45 |

| Consult factory for speeds less than 45 rpm |

| Maximum Discharge Pressure | |

| Metallic Heads: | |

| T100E | 1500 psi (103 bar) |

| T100F | 1850 psi (128 bar) |

| T100H | 2100 psi (145 bar) |

| Maximum Inlet Pressure | 500 psi (34 bar) |

| Operating Temperature | |

| Maximum: | 180 ̊F (82.2 ̊C) |

| Minimum: | 40 ̊F (4.4 ̊C) |

| Consult factory for temperatures outside this range | |

| Maximum Solids Size | 800 microns |

| Input Shaft | Left or Right Side |

| Inlet Ports | 3-1/2 inch Class 300 RF ANSI Flange |

| Discharge Ports | 2 inch Class 900 RF ANSI Flange |

| Plunger Stroke Length | 3-1/2 inch (88.9 mm) |

| Shaft Diameter | 3 inch (76.2 mm) |

| Shaft Rotation | Uni-directional (See rotation arrow.) |

| Oil Capacity | 18 US quarts (17 liters) - blank back cover |

| 20.5 US quarts (19.4 liters) - oil level back cover | |

| See page 5 for oil selection and specification. | |

| Weight | |

| Metallic Heads: | 1100 lbs. (499 kg) |

| Fluid End Materials | |

| Manifold: | Nickel Aluminum Bronze (NAB) |

| Duplex Alloy 2205 Stainless Steel | |

| 316L Stainless Steel CF3M | |

| Hastelloy CX2M | |

| Diaphragm/Elastomers: | FKM |

| Buna-N | |

| Aflas | |

| EPDM | |

| Diaphragm Follower Screw: | 316 Stainless Steel |

| Valve Spring Retainer: | 316 SST |

| Hastelloy C | |

| Check Valve Spring: | Elgiloy |

| Hastelloy C | |

| Valve Disc/Seat : | Tungsten Carbide |

| 17-4 Stainless Steel | |

| Nitronic 50 | |

| Hastelloy C | |

| Outlet Valve Retainer: | 316 Stainless Steel |

| Plug-Outlet Valve Port: | 316 Stainless Steel |

| Inlet Valve Retainer: | 316 Stainless Steel |

| Power End Materials | |

| Crankshaft: | Forged Q&T Alloy Steel |

| Connecting Rods: | Ductile Iron |

| Crossheads: | 12L14 Steel |

| Crankcase: | Ductile Iron |

| Bearings: | Spherical Roller/Journal (main) |

| Steel Backed Babbit (crankpin) | |

| Bronze (wristpin) |

Hydra-Cell Pumps for Mining, Tunneling, Quarrying & Dust Suppression

Applications by Mining Market

- Borehole Stabilization (Injecting bentonite and other substances)

- Liquid Explosives (Charging liquid explosives into blast holes and rigs)

- Drill Head Cooling (Cooling the picks and coal cutters and tunneling machines while reducing dust generation)

- Hazardous Chemical Pumping (Metering hazardous solutions in metal extraction)

- Conveyor Cleaning (24/7 continuous duty in high-pressure jet cleaning)

- Gland Seal Flushing (Protecting large slurry pumps from seal damage)

- Gas Extraction (Powering a Venturi jet pump to lift drillhole water and release gas to the surface)

Have a Fluid Handling Problem? We can help you find a Pumping Solution.

John Brooks Company caters to diverse industries, offering suitable pump solutions for nearly all fluid handling needs - including yours! Our success hinges on fostering a collaborative partnership with you, where we help you find a tailored solution to enhance your systems, boost productivity, and minimize operational expenses

Consult with a John Brooks Company Pump expert today to help you determine the most suitable pump type for your application needs.