Seal-less Pumps offer an affordable solution for a high inlet/suction pressure challenge – this is how we quickly helped an Oil & Gas Company solve issues with their sour condensate pumping application.

The Challenge: A Seal-less Pump Design with High Inlet/Suction Pressure – Needed in a Hurry

We partnered with a Calgary-based engineering firm to quickly design and supply a seal-less pumping solution for a high-pressure sour (natural gas) hydrocarbon condensate project for a significant Albertan oil & gas company.

The main challenge with pumping the sour condensate was that it needed to be pumped with a high pump inlet suction pressure of 580 PSI to keep it in a liquid state. Furthermore, the discharge injection pressure was only 682 PSI, resulting in a 102 PSI differential. The high inlet/suction pressure presented a considerable challenge for many typical pumps.

The Solution: Economical Hydra-Cell Seal-less Pumps with High Suction

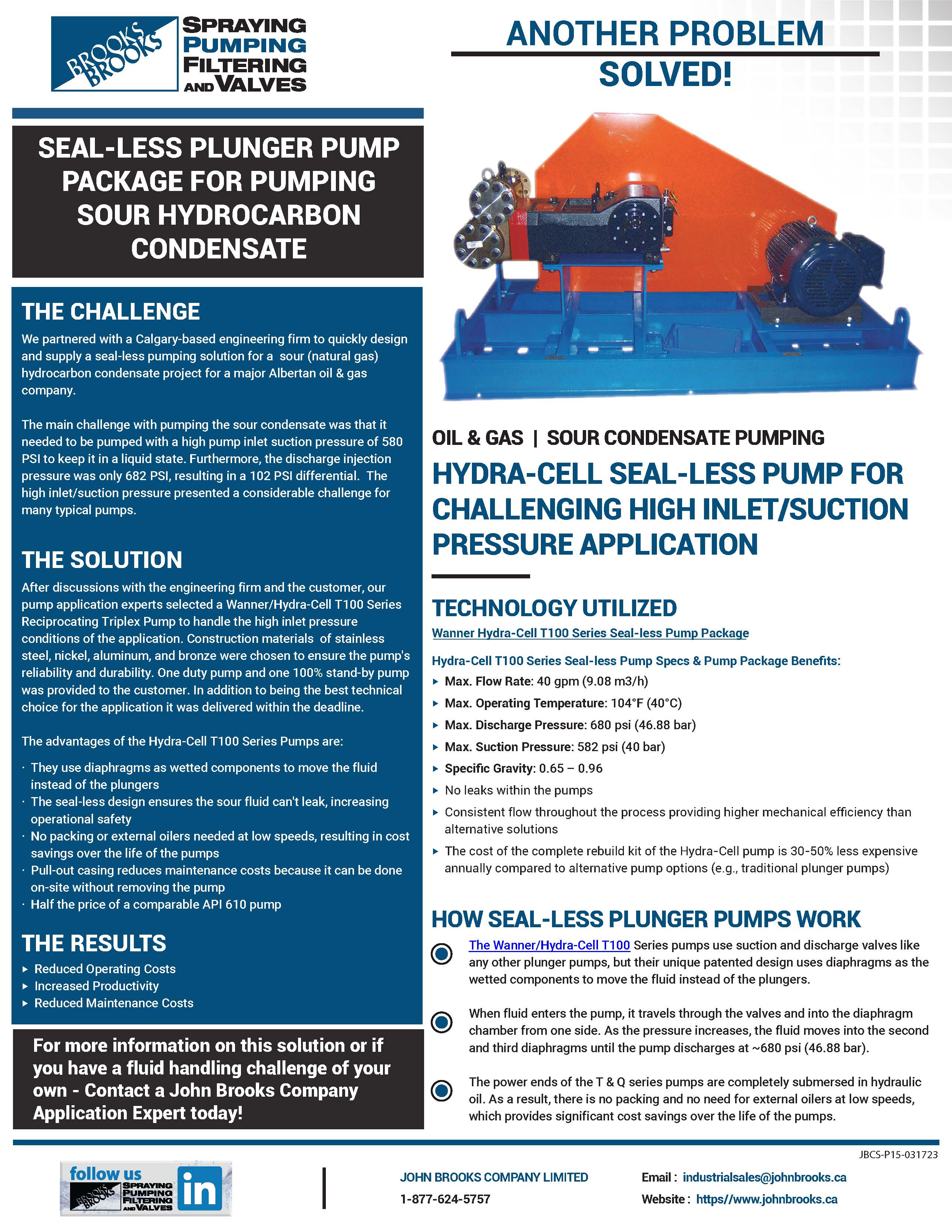

Our pump application experts selected a Wanner/Hydra-Cell T100 Series Reciprocating Triplex Pump to handle the high inlet pressure conditions of the application.

Our specialists determined the correct construction materials (stainless steel, nickel, aluminum, and bronze) to ensure the pump'spump's reliability and durability. In discussions with the engineering firm and the customer, it was agreed that the selected Hydra-Cell T100 pump package was technically the right choice to solve the application challenge. In addition to being the right technical choice, we supplied the pump package promptly that met the customer'scustomer's needs.

The Advantages of Hydra-Cell T100 Series Pumps :

- They use diaphragms as wetted components to move the fluid instead of the plungers

- The seal-less design ensures the sour fluid can't leak, increasing operational safety

- No packing or external oilers are needed at low speeds, resulting in cost savings over the life of the pumps

- Pull-out casing reduces maintenance costs because it can be done on-site without removing the pump

- They were half the price of a comparable API 610 pump

We supplied the customer with one duty pump and one 100% stand-by pump.

The Result: An Affordable, Working Pump Solution that Met the Specs and Was Delivered on Time

The Hydra-Cell pump successfully performed the customer'scustomer's application specifications, and we delivered it within their deadline.

The Results:

- No leaks within the pumps

- Consistent flow throughout the process provides higher mechanical efficiency than alternative solutions

- The cost of the complete rebuild kit of the Hydra-Cell pump is 30-50% less expensive annually compared to alternative pump options (e.g., traditional plunger pumps)

Pump Technology Used

We solved the customer'scustomer's problems using Wanner/Hydra-Cell T100 Series Seal-less Pump Package.

Hydra-Cell T100 Series Pump Specs

- Flow Rate: 40 gpm (9.08 m3/h)

- Suction Pressure: 582 psi (40 bar)

- Discharge Pressure: 680 psi (46.88 bar)

- Operating Temperature: 104°F (40°C)

- Specific Gravity: 65 – 0.96

Other Features & Benefits of Hydra-Cell T100 Series Pumps

- 30% – 50% initial costs savings because Hydra-Cell seal-less pumps use lower horsepower motors to achieve the same flow rates and pressures as other pumps

- Seal-less design reduces maintenance and repair expenditures

- Operates at 85-90% energy efficiency to reduce operating costs

- Tolerates abrasive solids up to 800µm non-ideal operating conditions

- Typically runs up to 6,000 hours between lubricating oil changes.

How Seal-less Plunger Pumps Work

- Wanner/Hydra-Cell T100 Series pumps use suction and discharge valves like other plunger pumps. Still, their unique patented design uses diaphragms as the wetted components to move the fluid instead of the plungers. This design is why the Wanner/Hydra-Cell T & Q series pumps are the only seal-less plunger pumps on the market.

- Fluid entering the pump travels through the valves and into the diaphragm chamber from one side. As the pressure increases, the liquid moves into the second and third diaphragms until the pump discharges at ~680 psi (46.88 bar).

- The power ends of the T & Q series pumps are entirely submersed in hydraulic oil. As a result, there is no packing and no need for external oilers at low speeds, which provides significant cost savings over the life of the pumps.