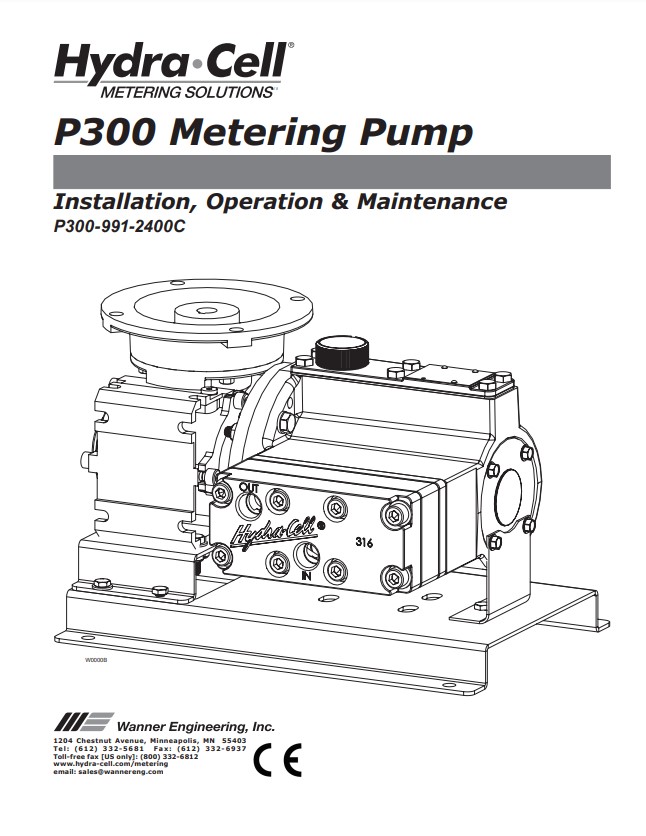

Hydra-Cell P300 Series Pumps Electronic Precision Metering

Versatile, Reliable Pumps for a Wide Range of Applications

- Designed to handle a wide range of fluids from clear water to thick slurries

- Electronic flow control increases accuracy and reliability

- Multiple diaphragm design provides linear, virtually pulse-less flow

- Smaller footprint saves valuable space

- One pump covers a wide range of flows and pressures - reducing inventory requirements with fast, simple field conversion

- Duplexing option doubles capacity and equipment savings

- Hydraulically-actuated, balanced diaphragms provide superior performance across entire pressure range

- Rugged construction with a variety of affordable choices for liquid end, diaphragm and check valve materials

| Maximum Flow Rate: | 81.4 gph |

| Maximum Pressure: | 2500 psi (172 bar) for Metallic Pump Heads |

| 350 psi (24 bar) for Non-metallic Pump Heads |

Hydra-Cell Electronic Precision Metering Specifications

________________________________________________________________________________________________________________________

| Diaphragms per Liquid End | 3 |

| Flow Control | Electronic variable speed drive |

| Maximum Discharge Pressure | |

| Metallic Heads: | 2500 psi (172 bar) |

| Maximum Inlet Pressure | 500 psi (34 bar) |

| Maximum Operating Temperature | |

| Metallic Heads: | 250 ̊F (121 ̊C)* |

| Inlet Port | 1/2 inch NPT or BSPT |

| Discharge Port | 1/2 inch NPT or BSPT |

| Weight (less motor)** | |

| Metallic Heads: | 54.5 lbs (24.7 kg) |

| Dimensions (less motor)** | |

| Metallic Heads: | 15.79” W x 12.25” D x 9.46” H |

| (401.2 mm W x 311.0 mm D x 240.2 mm H) | |

| * Consult factory for correct component selection for temperatures from 160 ̊F (71 ̊C) to 250 ̊F (121 ̊C). | |

| ** For 56C motor frame only. Consult factory for other motor frame sizes. | |

________________________________________________________________________________________________________________________

Hydra-Cell Pumps for Mining, Tunneling, Quarrying & Dust Suppression

Applications by Mining Market

- Borehole Stabilization (Injecting bentonite and other substances)

- Liquid Explosives (Charging liquid explosives into blast holes and rigs)

- Drill Head Cooling (Cooling the picks and coal cutters and tunneling machines while reducing dust generation)

- Hazardous Chemical Pumping (Metering hazardous solutions in metal extraction)

- Conveyor Cleaning (24/7 continuous duty in high-pressure jet cleaning)

- Gland Seal Flushing (Protecting large slurry pumps from seal damage)

- Gas Extraction (Powering a Venturi jet pump to lift drill hole water and release gas to the surface)

Have a Fluid Handling Problem? We can help you find a Pumping Solution.

John Brooks Company caters to diverse industries, offering suitable pump solutions for nearly all fluid handling needs - including yours! Our success hinges on fostering a collaborative partnership with you, where we help you find a tailored solution to enhance your systems, boost productivity, and minimize operational expenses

Consult with a John Brooks Company Pump expert today to help you determine the most suitable pump type for your application needs.