Gosco S-Class Cryogenic Valve Overview

Gosco S-Class Cryogenic Valves can handle temperatures down to -270°C/-454°F. Options include: A 12″ bonnet extension, live-loaded encapsulated seats for bi-directional sealing, high pressure designs (Grayloc hubs for pressures that exceed Class 4500), our patented S-Class shaft sealing system, and a fully grounded shaft and ball. We also offer Monel trim, an arcuate cut ball and oxygen cleaning for liquid oxygen service. A bolt-on retrofit kit is also available.

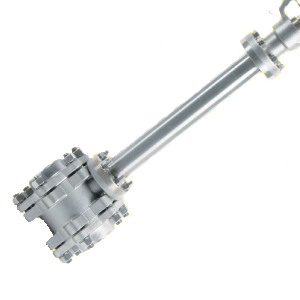

Cryogenic Extension

In cryogenic applications, an ice ball develops around the valve that is often large enough to cover the handle/actuator. S-Class Cryogenic Valves feature a 12” bonnet extension that is always taller than the ice ball, and allows access to the packing adjustments. The extension is also designed to allow the process media to vaporize and travel up the cryogenic extension, creating a gas pad that insulates the packing from the cryogenic temperatures. Cryogenic valves should always be installed at 45° to prevent cryogenic liquids from flowing down to the packing and shrinking it, causing leaks.

Bolt-on Retrofit Kit

When the soft goods need to be replaced, Gosco offers a bolt-on retrofit kit for our cryogenic valves. This fully assembled bonnet has new packing and gaskets, and has been pre-tested to 1.5 times the maximum pressure rating of the valve. The customer simply has to remove the bolts holding the old cryogenic extension to the body, and replace it with the new one. We can also ship new seats and a drilled ball with the retrofit kit, so you can convert a standard S-Class valve to a full cryogenic valve.

Exotic Trim

Gosco S-Class Cryogenic Valves can be custom fitted with several exotic trim options. Monel is a non-sparking metal, making it perfect for oxygen service. In addition to machining the ball out of Monel, we design it so that all edges in the process flow are rounded. This reduces velocities that can cause explosions in an oxygen line. A Niton analyzer is used to do full Positive Material Identification (PMI) on all exotic trim options.

Oxygen Cleaning

Oxygen is extremely explosive and even a tiny particle could cause a spark, potentially causing an explosion in the line. Valves in oxygen service must be oxygen cleaned and bagged in order to guarantee that the valve is 100% free of debris. Special facilities and procedures including a positively-charged clean room, approved cleaning solutions, and ultraviolet inspection lighting are available at Gosco Valves, if you require oxygen cleaning.

Exotic Alloys

Cast, forged or bar stock, Gosco manufactures ball valves out of any metal – even specialty metals that require vacuum casting (like titanium). We are not restricted to making just the body from exotic alloys – we can manufacture any component to suit your needs, right down to the bolting. Our engineering team at Gosco Valves has extensive experience in corrosive applications, and can recommend the appropriate material to use for specific media.

Arcuate Cut Ball

An arcuate cut is a profile in the ball that reduces velocity as the valve opens and closes. When a standard ball valve is in the first and last 10° of opening/closing, velocities are very high (especially in the corners), and erosion occurs. With an arcuate cut, the opening on the ball is almost three times as large. This reduces the velocity by spreading out the flow through a larger opening, which reduces wear on the ball and seats. BORONIZING must be used to harden arcuate cut profiles because HVOF coatings are line of sight and can not evenly coat the ball.

Encapsulated “Soft” Seats

S-Class encapsulated seats are used for high cycle and high pressure applications. Our proprietary live-loaded design allows us to completely encapsulate the insert on all four sides, leaving only a small section of the “Soft” material exposed for sealing. The insert is held in place with “barbs” that prevent it from extruding out of the carrier. A special fixture compresses the seat assembly to 3 times the maximum pressure rating of the valve, so that the insert takes a compression set. The seat profile is then machined in to the insert, and it is match lapped to the ball.

Bi-Directional Sealing

The S-Class Cryogenic Valve has an option for a drilled ball on the upstream side, or a truly

bi-directional design that relieves pressure in the body/ball cavity. It doesn’t have a “Preferred Direction” and seals bubble tight in both directions with a full pressure differential, OR a 1psi drop. Both seats are live loaded with wave springs, so any pressure build-up in the valve cavity, collapses the spring on the low pressure side, and relieve the pressure in the ball/body cavity.

-

Cryogenic Sizes

NPS ½ FP to NPS 16 SP

½″ FP to 16″ SP -

Cryogenic Connections

150# to 4500#, NPT, SW,

BW, Graylock and Custom -

Cryogenic Applications

Low temperatures/high pressures exotic alloys, and custom designs

-

Cryogenic Temperatures

-270°C to 200°C

-454°F to 392°F