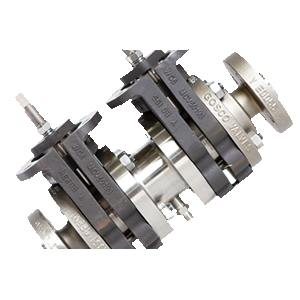

Gosco F-Class Block & Bleed Valves Overview

With Gosco Valves’ cutting edge live-loaded seat technology,Gosco F-Class Block & Bleed Valves can be configured with soft or metal seats and meet both API 6D, and OSHA block & bleed definitions. With our proprietary boronizing procedure for trim hardening, encapsulated soft seats and any exotic alloy options, the Gosco block & bleed valves are extremely versatile and can tackle the toughest severe service applications.

Configurations

Gosco F-Class Block & Bleed Valves are essentially two bi-directional valves with a bleed valve between them. Since both valves are completely bi-directional, we meet all definitions of API 6D for double block & bleed (DBB) and double isolation & bleed (DIB), as well as OSHA double block & bleed (DBB).

Bi-Directional Sealing

The Fab Valve design is completely symmetrical, and seals bubble tight in both directions with both a full pressure differential or a 1 PSI differential. Gosco Valves are completely bi-directional so installers do not need to worry about flow direction and/or high pressure sides.

Exotic Alloys

We matched all the internals of the Fab Valve to the most corrosion resistant spring material on the market – Inconel 718. The four components that are left can be manufactured from any commercially available metal, including Hastelloy, Inconel, Titanium, Tantalum, Monel, Alloy 20, Duplex, etc. The horseshoe body plates for bolting containment never come in to contact with the process media, so they’re cast from less expensive ASTM A217 Grade WC6 material. You get an exotic alloy valve for less money, and you have the same Gosco quality.

Superior Trim Hardening

BORONIZING is a thermo-chemical surface hardening process that creates a surface layer that’s so hard, it can’t be measured on the Rockwell C Scale. We use Inconel 718 because it is the best overall metal for corrosion, high temperature, and wear resistance. Our PROPRIETARY BORONIZING has a layer depth over 100 microns (0.004”) and a hardness between HV 2500-2700.

Compared to HVOF coatings, BORONIZING is:

Substantially harder, markedly more wear resistant, impervious to corrosion, and is capable of handling huge temperature shocks without spalling or flaking.

Seat/Spring Design

Gosco’s patented seat/spring design is perfect for powder/catalyst applications. When powder gets trapped in the spring cavity, it causes the valve to “lock up”. To solve this issue, Gosco uses a completely different approach to the competition – instead of trying to seal the spring from the media, we deliberately open up the cavity around the spring. This allows the media to flow around the spring, but also allows it to escape just as easily. Media never gets trapped in the valve, so we never have issues with valves “locking up”.

-

Block & Bleed Sizes

NPS ½ FP to NPS 8 SP

½″ FP to 8″ SP -

Block & Bleed Connections

150#, 300#, 600#,

NPT, SW, butt weld -

Block & Bleed Configurations

On/Off, Vari-V Control,

Double Isolation and Bleed -

Block & Bleed Temperatures

-50°C to 593°C

-58°F to 1100°F